Albert J Moses

age ~62

from West Chester, PA

- Also known as:

-

- Bert J Moses

- Albert J Moss

- Bert A Moses

- Al J Moses

- Michael Petrollese

- Phone and address:

-

1204 Withers Way, West Chester, PA 19382

6107932637

Albert Moses Phones & Addresses

- 1204 Withers Way, West Chester, PA 19382 • 6107932637

- 819 Sharon Aly, West Chester, PA 19382 • 6106925925

- 934 Hill St, West Chester, PA 19380 • 6106925925

- Orrstown, PA

- 2129 182Nd St, Omaha, NE 68130 • 4029336038

- Broomall, PA

- Hopewell Junction, NY

Us Patents

-

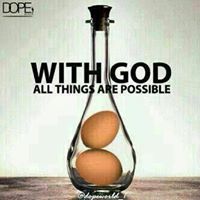

Sealed-System Critical Temperature Indicator

view source -

US Patent:20060065183, Mar 30, 2006

-

Filed:Sep 24, 2004

-

Appl. No.:10/949485

-

Inventors:Michael Drummond - Malvern PA, US

Albert Moses - West Chester PA, US -

Assignee:Drummond Scientific Company - Broomall PA

-

International Classification:G01K 1/02

-

US Classification:116217000

-

Abstract:An apparatus that indicates whether an object has been exposed to a predetermined critical temperature T. The apparatus housing has a reservoir portion and a capillary tube portion in fluid connection with the reservoir portion. A first fluid is contained within the reservoir portion. A second fluid is contained within the capillary portion. A barrier is located intermediate the first fluid and second fluid. The barrier prevents the first and second fluids from intermixing until the apparatus is exposed to the critical temperature, and then allows at least a portion of the second fluid to mix with the first fluid when the apparatus is exposed to the critical temperature. An observable characteristic of one of the fluids irreversibly changes when the apparatus is exposed to the critical temperature. The housing completely encapsulates the fluids and barrier within the housing and prevents evaporation of the fluids and barrier from the housing.

-

Pipette With Contamination Indicator

view source -

US Patent:20070086924, Apr 19, 2007

-

Filed:Oct 18, 2005

-

Appl. No.:11/252833

-

Inventors:Albert Moses - West Chester PA, US

-

Assignee:Drummond Scientific Company - Broomall PA

-

International Classification:B01L 3/02

-

US Classification:422100000

-

Abstract:A disposable, contamination-indicating pipette for metering liquids containing a specified agent. The pipette has a main body portion having a volume V and a diameter D, an open-ended upper connection portion, and an open-ended lower tip portion. An indicator in the connection portion provides an observable indication that liquid has entered the connection portion.

-

Dual-Temperature, Sealed-System Critical Temperature Indicator

view source -

US Patent:20110011330, Jan 20, 2011

-

Filed:Jul 20, 2009

-

Appl. No.:12/506248

-

Inventors:Albert J. Moses - West Chester PA, US

Michael E. Drummond - Broomall PA, US -

Assignee:Drummond Scientific Company - Broomall PA

-

International Classification:G01K 1/02

-

US Classification:116216

-

Abstract:An inexpensive, disposable apparatus that visually indicates whether an object has been exposed to either one or both of two predetermined critical temperatures such as a critical high T or a critical low T temperature. The apparatus includes a housing having a reservoir portion, and a capillary tube portion with a first, proximal end in fluid connection with the reservoir portion and an open, second, distal end. A first fluid is contained within the reservoir portion and a portion of the proximal capillary tube portion. A second fluid is contained within the capillary portion intermediate the first fluid and the distal end. A barrier is located intermediate the first fluid and the second fluid. The barrier prevents the first and second fluids from intermixing until the apparatus is exposed to T and then allows at least a portion of the second fluid to mix with the first fluid when the apparatus is exposed to T and irreversibly changes an observable characteristic of the second fluid. An indicator material is fixed proximate to and in fluid communication with the distal end of the capillary tube portion. The indicator material has an observable characteristic that irreversibly changes at T when contacted with the second fluid. An outer sheath encapsulates the indicator and the distal open end of the capillary tube portion to prevent the fluids and barrier from evaporating from the housing.

Name / Title

Company / Classification

Phones & Addresses

President

Quality Carpet Cleaning Inc

Carpet/Upholstery Cleaning

Carpet/Upholstery Cleaning

3233450309

President , Director

Christian Faith Missionary Baptist Church of Port Arthur, Texas

Isbn (Books And Publications)

Durable Powers of Attorney and Health Care Directives

view sourceAuthor

Albert L. Moses

ISBN #

0071725083

Drafting the Durable Power of Attorney: A Systems Approach

view sourceAuthor

Albert L. Moses

ISBN #

0960845011

Resumes

Senior Director, Medical Device And Combination Products Quality At Teva Pharmaceuticals

view sourceLocation:

West Chester, PA

Industry:

Pharmaceuticals

Work:

Teva Pharmaceuticals

Senior Director, Medical Device and Combination Products Quality at Teva Pharmaceuticals

Streck Aug 2009 - May 2012

Director of Quality and Regulatory

Drummond Scientific Co Jun 1992 - Aug 2009

Director of Quality and Regulatory Compliance

Centocor 1986 - 1992

Iqa Unit Manager

Senior Director, Medical Device and Combination Products Quality at Teva Pharmaceuticals

Streck Aug 2009 - May 2012

Director of Quality and Regulatory

Drummond Scientific Co Jun 1992 - Aug 2009

Director of Quality and Regulatory Compliance

Centocor 1986 - 1992

Iqa Unit Manager

Education:

West Chester University of Pennsylvania

Bachelors, Bachelor of Science, Biology West Chester University of Pennsylvania

Master of Business Administration, Masters, Bachelors, Bachelor of Science

Bachelors, Bachelor of Science, Biology West Chester University of Pennsylvania

Master of Business Administration, Masters, Bachelors, Bachelor of Science

Skills:

Quality System

Quality Auditing

Fda

Medical Devices

Iso 13485

Gmp

Iso

Pharmaceutical Industry

Change Control

21 Cfr Part 11

Capa

Process Improvement

Regulatory Submissions

Validation

Regulatory Affairs

Drug Delivery

U.s. Food and Drug Administration

Iso 14971

Contract Negotiation

Glp

Ivd

V&V

Gxp

Regulatory Requirements

Verification and Validation

Combination Products

European Union

Design Control

Business Process Improvement

21 Cfr Part 820

Pen Injectors

Needle Based Injection Systems

In Vitro Diagnostics

21 Cfr Part 4

Quality Assurance

Quality Control

Quality Auditing

Fda

Medical Devices

Iso 13485

Gmp

Iso

Pharmaceutical Industry

Change Control

21 Cfr Part 11

Capa

Process Improvement

Regulatory Submissions

Validation

Regulatory Affairs

Drug Delivery

U.s. Food and Drug Administration

Iso 14971

Contract Negotiation

Glp

Ivd

V&V

Gxp

Regulatory Requirements

Verification and Validation

Combination Products

European Union

Design Control

Business Process Improvement

21 Cfr Part 820

Pen Injectors

Needle Based Injection Systems

In Vitro Diagnostics

21 Cfr Part 4

Quality Assurance

Quality Control

Engineer

view sourceWork:

Stiver

Engineer

Engineer

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view source

Albert Moses

view sourceClassmates

Albert Moses

view sourceSchools:

West High School Auburn WA 1995-1999

Community:

Eric Loughmiller, Joe Adams, Lonnie Brown, Mike Petersen

Albert E Moses

view sourceSchools:

Harrisonville High School Harrisonville MO 1976-1980

Community:

Marie Thomas, Linda Gordon, Damon Fair, Richonda Mullen, Sherry Grant

West High School, Auburn,...

view sourceGraduates:

Mimi Haskins (1992-1996),

Mike Petersen (1983-1987),

Albert Moses (1995-1999),

Amanda Fry (1994-1998),

Arianna Lancastria (1990-1994),

Angela Gaffke (1996-1996)

Mike Petersen (1983-1987),

Albert Moses (1995-1999),

Amanda Fry (1994-1998),

Arianna Lancastria (1990-1994),

Angela Gaffke (1996-1996)

Port Arthur Memorial High...

view sourceGraduates:

Travis Chisholm (1999-2003),

Markiese Cohea (2003-2007),

Sandra Bennette (1970-1974),

Karen Harmon (1986-1990),

Albert Moses (2000-2004)

Markiese Cohea (2003-2007),

Sandra Bennette (1970-1974),

Karen Harmon (1986-1990),

Albert Moses (2000-2004)

Myspace

Youtube

Googleplus

Albert Moses

Albert Moses

Albert Moses

Albert Moses

Flickr

Get Report for Albert J Moses from West Chester, PA, age ~62