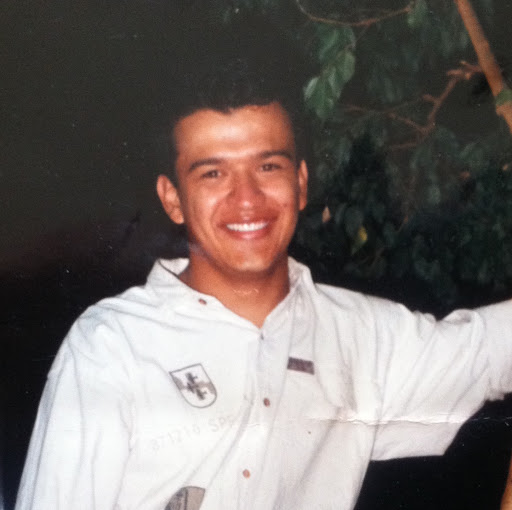

Alexander Paul Calderon

age ~58

from Tracy, CA

- Also known as:

-

- Alexander P Calderon

- Alexander Adela Calderon

- Alexander Te Calderon

- Alex P Calderon

- Aley Calderon

- Calderon Alexanderp

- Cynthia Calderon

- Alexander Calderdon

- Phone and address:

-

1261 Appalosa Way, Tracy, CA 95376

2098361242

Alexander Calderon Phones & Addresses

- 1261 Appalosa Way, Tracy, CA 95376 • 2098361242

- Fremont, CA

- Colfax, CA

- 2839 Sombrero Cir, San Ramon, CA 94583

- Union City, CA

Resumes

Service Agent

view sourceWork:

Service Agent

Alexander Calderon

view source

Alexander Calderon

view source

Alexander Nernandez Calderon

view source

Alexander Calderon

view source

Operations Associate

view sourceWork:

Kohl's

Operations Associate

Operations Associate

Us Patents

-

Combination Homogenizer-Vacuum Loader For Meat Products With Improved Ring Seal

view source -

US Patent:53340817, Aug 2, 1994

-

Filed:Jan 27, 1992

-

Appl. No.:7/826904

-

Inventors:Alexander Calderon - Fremont CA

-

International Classification:A22C 1102

-

US Classification:452 35

-

Abstract:A combination homogenizer-vacuum loader for a machine that stuffs meat product into a casing which includes an upright cylindrical chamber that can be evacuated and an agitator assembly that is rotated inside the chamber. An entrance port with a sliding gate valve is located on the side of the chamber so that when the valve is opened, ground meat is drawn by vacuum into the chamber. An exit port is located on the floor of the cylinder. The agitator assembly is detachably mounted on one end of a spindle having its other end external to the chamber for attachment to a drive means. A number of agitator assemblies are provided, each having a configuration designed to homogenize a particular meat product having its own consistency, depending on content of fat, moisture, and fiber. A ring seal features three elastomeric seals operating in combination to provide a reliable vacuum seal between the homogenizing unit and the meat stuffing machine. The homogenizer may be lifted off the meat stuffing machine by actuating a hydraulic ram hingably attached to the homogenizer and base stand.

-

Combination Homogenizer-Vacuum Loader For Meat Products

view source -

US Patent:51293161, Jul 14, 1992

-

Filed:Jan 28, 1991

-

Appl. No.:7/647462

-

Inventors:Alexander Calderon - Fremont CA

-

International Classification:B01F 700

-

US Classification:99472

-

Abstract:A combination homogenizer-vacuum loader for a machine that stuffs meat product into a casing which includes an upright cylindrical chamber that can be evacuated and an agitator assembly that is rotated inside the chamber. An entrance port with a sliding gate valve is located on the side of the chamber so that when the valve is opened, ground meat is drawn by vacuum into the chamber. An exit port is located on the floor of the cylinder. The agitator assembly is detachably mounted on one end of a spindle having its other end external to the chamber for attachment to a drive means. A number of agitator assemblies are provided, each having a configuration designed to homogenize a particular meat product having its own consistency, depending on content of fat, moisture, and fiber.

-

Active Seat Bolster Adjustment Based On Occupant Pressure Map And Method

view source -

US Patent:20190031057, Jan 31, 2019

-

Filed:Jul 28, 2017

-

Appl. No.:15/663321

-

Inventors:- Dearborn MI, US

Andres Senatore - Mountain View CA, US

John Wayne Jaranson - Dearborn MI, US

Alexander Alborzi Calderon - San Carlos CA, US -

International Classification:B60N 2/42

B60R 21/015

B60N 2/02 -

Abstract:A seat assembly includes one or more adjustable components disposed in a seat portion or a seatback of the seat assembly and are actively operable between stowed and deployed positions based on real-time occupant position information. A controller is operably coupled to the adjustable components and configured to adjust the adjustable components towards the deployed position when a pressure force is detected by one or more sensors disposed in either the seat portion or the seatback, or both. The pressure forces are applied by the vehicle occupant as the vehicle occupant applies pressure to portions of the vehicle seat during movement of the vehicle. The adjustable components are moveable to a degree that is calculated as a function of the pressure value sensed by the sensors in the seat assembly.

-

Active Seat Bolster Adjustment Based On Occupant Pressure Map And Method

view source -

US Patent:20190031058, Jan 31, 2019

-

Filed:Oct 13, 2017

-

Appl. No.:15/783261

-

Inventors:- Dearborn MI, US

Andres Senatore - Mountain View CA, US

John Wayne Jaranson - Dearborn MI, US

Alexander Alborzi Calderon - San Carlos CA, US -

International Classification:B60N 2/42

B60N 2/02

B60R 21/015 -

Abstract:A seat assembly includes one or more adjustable components disposed in a seat portion or a seatback of the seat assembly. The adjustable components are operable between stowed and deployed positions. A controller is operably coupled to the adjustable components and configured to adjust the adjustable components towards the deployed position when a seat occupant is seated in the seat assembly. The controller moves one or more of the adjustable components towards the deployed position until a pressure force is detected by one or more sensors disposed in either the seat portion or the seatback, or both. The pressure forces are detected by the sensors as one or more of the adjustable components contacts a vehicle occupant. Movement of the adjustable components may cease immediately when a pressure value is detected and may also continue until a threshold pressure value is reached.

-

Active Seat Bolster Adjustment Based On Occupant Pressure Map And Method

view source -

US Patent:20190031137, Jan 31, 2019

-

Filed:Jul 28, 2017

-

Appl. No.:15/663342

-

Inventors:- Dearborn MI, US

Andres Senatore - Mountain View CA, US

John Wayne Jaranson - Dearborn MI, US

Alexander Alborzi Calderon - San Carlos CA, US -

International Classification:B60R 22/44

B60R 21/015

B60N 2/02 -

Abstract:A method for actively adjusting an adjustable component in a vehicle seat includes the steps of: (1) providing a seat assembly having a seat portion with first and second side bolsters disposed on opposite sides of the seat portion, first and second adjustable components and first and second sensors disposed in the first and second side bolsters, and a controller operably coupled to both the first and second adjustable components and the first and second sensors; (2) detecting a pressure value using one of the first and second sensors; (3) determining if the pressure value exceeds a threshold value; and moving an articulating support plate of the adjustable component associated with the sensor detecting the pressure value towards an extended position from a retracted position to a degree commensurate with pressure value detected.

-

Active Seat Bolster Adjustment Based On Occupant Pressure Map And Method

view source -

US Patent:20190031138, Jan 31, 2019

-

Filed:Oct 13, 2017

-

Appl. No.:15/783292

-

Inventors:- Dearborn MI, US

Andres Senatore - Mountain View CA, US

John Wayne Jaranson - Dearborn MI, US

Alexander Alborzi Calderon - San Carlos CA, US -

International Classification:B60R 22/44

B60N 2/02

B60R 21/015 -

Abstract:A method for adjusting an adjustable component in a seat assembly includes the steps of: (1) providing a seat assembly having an adjustable support plate and a sensor; (2) supporting a seat occupant on the seat assembly; (3) moving the support plate into contact with the seat occupant; (4) sensing a pressure value applied to the support plate using the sensor as the support plate contacts the seat occupant; and (5) retaining the support plate in a deployed position. The movement of the support plate is configured to cease when the pressure value is initially detected or when the pressure value exceeds a predetermined threshold.

Googleplus

Alexander Calderon

Work:

Surfaces/desing gallery - Fabricación e instalation de granite (2011)

Alexander Calderon

Alexander Calderon

Relationship:

Single

Alexander Calderon

Relationship:

In_a_relationship

Alexander Calderon

Alexander Calderon

Alexander Calderon

Alexander Calderon

Alexander Calderon

view source

Alexander Calderon

view source

Alexander James Calderon

view source

Alexander Calderon

view source

Alexander Calderon

view source

Alexander Calderon

view source

Alexander Calderon

view source

Alexander Van Calderon

view sourceClassmates

Alexander Calderon

view sourceSchools:

William T. Machan Elementary School Phoenix AZ 2002-2006

Community:

Kathy Norton, Cynthia Carlton, Gayle Crittenden, John Harris, David Molina

Alexander Calderon

view sourceSchools:

Huntley High School Huntley IL 1999-2003

Community:

Jan Goecks

Alexander Serna Calderon

view sourceSchools:

Colegio Cafam High School Bogota Colombia 1999-2003

Community:

Nelsy Acero

Alexander Duarte (Calderon)

view sourceSchools:

Henry M. Flagler Elementary School Miami FL 1991-1995

Community:

Anamaria Ana, Gayle Rocap, Richard Rump, Ed Ochoa

Henry M. Flagler Elementa...

view sourceGraduates:

Jennifer Barillas (1997-2001),

Marilyn Ravelo (1964-1970),

Alexander Calderon (1991-1995)

Marilyn Ravelo (1964-1970),

Alexander Calderon (1991-1995)

William T. Machan Element...

view sourceGraduates:

Alexander Calderon (2002-2006),

Brent McDonald (1977-1981),

Izamar Loeza (2001-2005),

Maryann Geary (1974-1982)

Brent McDonald (1977-1981),

Izamar Loeza (2001-2005),

Maryann Geary (1974-1982)

Central High School, Memp...

view sourceGraduates:

cheryl hopson (1983-1987),

Paula Benovitz (1951-1955),

jerry jones (1975-1979),

sonya Delapaz (1974-1978),

alex calderon (1979-1983)

Paula Benovitz (1951-1955),

jerry jones (1975-1979),

sonya Delapaz (1974-1978),

alex calderon (1979-1983)

Worcester Voc-Tech High S...

view sourceGraduates:

Alex Calderon (2004-2008),

Matt Shircliff (1987-1991),

Alisha Johnston (1993-1997),

Tina Swanson (2004-2008),

John Patterson (1987-1991)

Matt Shircliff (1987-1991),

Alisha Johnston (1993-1997),

Tina Swanson (2004-2008),

John Patterson (1987-1991)

Youtube

Myspace

Alexander Calderon

view sourceLocality:

The Place Where The Desert Is Your Backyard

Gender:

Male

Birthday:

1948

Flickr

Get Report for Alexander Paul Calderon from Tracy, CA, age ~58