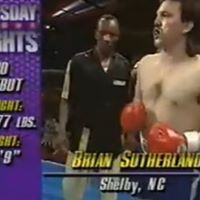

Brian P Sutherland

age ~44

from Hampshire, IL

- Also known as:

-

- Brian Patrick Sutherland

- Brian Patric Sutherland

Brian Sutherland Phones & Addresses

- Hampshire, IL

- South Elgin, IL

- Elgin, IL

- Chicago, IL

- Kane, IL

Work

-

Company:Highland group inc

-

Address:200 S Michigan Ave # 1000, Chicago, IL 60604

-

Phones:3128637500

-

Position:Owner

-

Industries:Computer Programming Services

Resumes

Branch Manager/Executive Mlo At Southeast Mortgage

view sourcePosition:

Branch Manager/Executive MLO at Southeast Mortgage, Branch Manager/Executive MLO at Southeast Mortgage, Branch Manager at Citizens Fidelity Mortgage

Location:

Suwanee, Georgia

Industry:

Financial Services

Work:

Southeast Mortgage since Feb 2011

Branch Manager/Executive MLO

Citizens Fidelity Mortgage since 1998

Branch Manager

Branch Manager/Executive MLO

Citizens Fidelity Mortgage since 1998

Branch Manager

Martial Arts Instructor

view sourceLocation:

Boulder, Colorado

Industry:

Professional Training & Coaching

Data Warehousing Consultant

view sourcePosition:

Owner at Zeniquity LLC

Location:

Austin, Texas

Industry:

Computer & Network Security

Work:

Zeniquity LLC since 2004

Owner

Owner

Education:

The University of Texas at Austin 2013 - 2016

Bachelor of Science, Electrical and Computer Engineering

Bachelor of Science, Electrical and Computer Engineering

Languages:

English

Japanese

Japanese

Brian Sutherland

view sourceLocation:

United States

Brian Sutherland

view sourceLocation:

United States

Brian Sutherland South Elgin, IL

view sourceWork:

Career Education Corporation

2012 to 2000

Document Imaging Supervisor Imaging Associate/Senior Document Imaging Associate/Document Imaging Team Lead

2004 to 2012

2012 to 2000

Document Imaging Supervisor Imaging Associate/Senior Document Imaging Associate/Document Imaging Team Lead

2004 to 2012

Education:

Loyola University Chicago

Chicago, IL

2003

Bachelor of Arts in Communication

Chicago, IL

2003

Bachelor of Arts in Communication

Brian Sutherland Chicago, IL

view sourceWork:

World Kitchen, LLC

May 2010 to 2000

Contract Engineer Metso Minerals

Brookfield, WI

Jan 2008 to Oct 2009

Design Engineer Springs Window Fashions, LLC

Middleton, WI

Jul 2007 to Jan 2008

Intern University of Wisconsin Engineering Department

2006 to 2006

Student Volunteer

May 2010 to 2000

Contract Engineer Metso Minerals

Brookfield, WI

Jan 2008 to Oct 2009

Design Engineer Springs Window Fashions, LLC

Middleton, WI

Jul 2007 to Jan 2008

Intern University of Wisconsin Engineering Department

2006 to 2006

Student Volunteer

Education:

University of Illinois

Chicago, IL

Jan 2011 to Jan 2013

MS in Energy Engineering University of Wisconsin

Madison, WI

Jan 2002 to Jan 2007

BS in Mechanical Engineering

Chicago, IL

Jan 2011 to Jan 2013

MS in Energy Engineering University of Wisconsin

Madison, WI

Jan 2002 to Jan 2007

BS in Mechanical Engineering

License Records

Brian J. Sutherland

License #:

E097985 - Expired

Category:

Emergency medical services

Issued Date:

May 4, 2013

Expiration Date:

Oct 2, 2015

Type:

Orange County EMS Agency

Isbn (Books And Publications)

Glazes from Natural Sources: A Working Handbook for Potters

view sourceAuthor

Brian Sutherland

ISBN #

0713442042

Glazes from Natural Sources: A Working Handbook for Potters

view sourceAuthor

Brian Sutherland

ISBN #

0713647558

Glazes from Natural Sources: A Working Handbook For Potters

view sourceAuthor

Brian Sutherland

ISBN #

0812219457

Name / Title

Company / Classification

Phones & Addresses

Highland Solutions

Computers Hardware. Software & Services. Web Design. Internet Services. Computers - Networks. Computers - Disaster Recovery

Computers Hardware. Software & Services. Web Design. Internet Services. Computers - Networks. Computers - Disaster Recovery

200 S Michigan Ave #1000, Chicago, IL 60604

3128637500, 8153521078

3128637500, 8153521078

Owner

Highland Group Inc

Computer Programming Services

Computer Programming Services

200 S Michigan Ave # 1000, Chicago, IL 60604

Website: highlandsolutions.com

Website: highlandsolutions.com

Secretary, Owner

Highland Group, Inc

Management Consulting Services · Custom Computer Programming Svcs

Management Consulting Services · Custom Computer Programming Svcs

200 S Michigan Ave, Chicago, IL 60604

3128637500

3128637500

Highland Solutions

Computers Hardware · Software & Services · Web Design · Internet Services · Computers - Networks · Computers - Disaster Recovery

Computers Hardware · Software & Services · Web Design · Internet Services · Computers - Networks · Computers - Disaster Recovery

200 S Michigan Ave #1000, Chicago, IL 60604

3128637500, 8153521078

3128637500, 8153521078

President

Anchor Advisors, Ltd.

Management Consulting · Business Consulting Services

Management Consulting · Business Consulting Services

5366 N Elston Ave SUITE #203, Chicago, IL 60630

Chicago, IL 60630

7732827677, 7739304619

Chicago, IL 60630

7732827677, 7739304619

Principal

Decision Design Corp

Business Services

Business Services

342 Park Ave, Glencoe, IL 60022

Principal

Media Propulsion

Communication Services

Communication Services

200 S Michigan Ave, Chicago, IL 60604

Us Patents

-

Method For Surface Stabilized Combustion (Ssc) Of Gaseous Fuel/Oxidant Mixtures And A Burner Design Thereof

view source -

US Patent:20160230986, Aug 11, 2016

-

Filed:Feb 5, 2016

-

Appl. No.:15/016469

-

Inventors:Vladimir SHMELEV - Moscow, RU

Nikolay VASILIK - Moscow, RU

Mark KHINKIS - Morton Grove IL, US

Aleksandr KOZLOV - Buffalo Grove IL, US

David CYGAN - Villa Park IL, US

David KALENSKY - Chicago IL, US

Brian SUTHERLAND - Chicago IL, US -

International Classification:F23D 14/14

F23D 14/84

F23D 14/08 -

Abstract:Methods of burning combustible gas mixtures on a surface of a permeable matrix providing surface stabilized combustion (SSC) with increasing amounts of radiation energy emitted by the surface of the permeable matrix and decreasing concentrations of pollutant components in the combustion products are provided. The gas mixture is fed to a burner that includes a permeable matrix material having a first thermal conductivity. The gas mixture is preheated as it travels through the permeable matrix material. The gas mixture is then combusted at or near exit pores and channels formed at a combustion surface of the permeable matrix material, the combustion surface at least in part coated with a coating material having a thermal conductivity less than the permeable matrix material thermal conductivity and a high optical transmittance in the infrared spectrum.

-

Porous Metal Foam Burner

view source -

US Patent:20150253005, Sep 10, 2015

-

Filed:Mar 7, 2014

-

Appl. No.:14/200567

-

Inventors:Brian Sutherland - Chicago IL, US

Michael JOHNSON - Elmhurst IL, US

Chakravarthy SISHTLA - Plainfield IL, US -

International Classification:F23D 14/16

-

Abstract:A gas burner including a gas distribution element and a metal foam matrix burner covering the distribution element. A heat sink partially surrounds, and is spaced apart from, the metal foam matrix. The heat sink has an open end to vent exhaust emissions. The gas burner provides reduced nitrous oxide and carbon monoxide emissions and effective heat transfer modes (conduction, convection and radiation) compared to state-of-the-art burner technologies.

Plaxo

Brian Sutherland

view sourceElgin, ILImaging Team Lead at Career Education Corporation

brian sutherland

view sourceActor

Brian Sutherland

view sourceEAST COAST CAPITAL

Classmates

Brian Sutherland

view sourceSchools:

Plymouth Salem High School Canton MI 1995-1999

Community:

Michelle Campagna, Lynn Koza, Rachelle Carrier

Brian Sutherland

view sourceSchools:

Whitewood High School Whitewood VA 1989-1993

Community:

Lori Rainey, Jackie Breeden, Carol Goss, Roger Cantrell, David Mullins

Brian Sutherland

view sourceSchools:

Crocus Plains Regional High School Brandon Palestinian Territory, Occupie 1992-1996

Community:

Malcolm Wall

Brian Sutherland

view sourceSchools:

Salome High School Salome AZ 1981-1985

Community:

Kim Ramsey, Debbie Hines, Michael Whitlow, Jason Himelstein

Brian Sutherland

view sourceSchools:

Daniel Boone High School Gray TN 1983-1987

Community:

Sherri Spell, Kathryn Moore, Jason Carter, George Mauk

Brian Sutherland

view sourceSchools:

Martin Luther King Elementary School Edison NJ 1994-1998

Community:

Marcus Neyor, Kalena Reeves, Olivia Chen, Dua Amit, Janay Wright, Daniel Ivasco

Brian Sutherland

view sourceSchools:

Brampton Centennial High School Brampton Morocco 1993-1997

Community:

Carol Fagan

Brian Sutherland

view sourceSchools:

Banting Memorial High School Alliston Morocco 1965-1969

Community:

Melody Kozeyah, Mike Kenny, Raymond Graham, Deborah Bishop, Lana King, Cindy Little

Youtube

Brian Sutherland Demo 2018 COMEDY

Brian Sutherland Demo Reel 2017 [email protected]... Represented by:...

-

Duration:2m 54s

Myspace

Brian Sutherland

view sourceGoogleplus

Brian Sutherland

Work:

Magic Geek, Inc - President (1994)

Falcon Vision, LLC - Partner (2009)

Falcon Vision, LLC - Partner (2009)

Education:

Antioch College - Business, Santa Barbara City College - General Studies, University of California, Santa Barbara - Computer Programing

Brian Sutherland

Work:

Synchronoss Technologies, Inc. - Business Analyst (2004)

Education:

East Stroudsburg University of Pennsylvania - Computer Security, Allentown Business School - Computer Science

Brian Sutherland

Work:

Build-A-Bear Workshop - Bear Stuffer

Education:

School for Scoundrels - Being Bad :D

Tagline:

Really?

Brian Sutherland

Work:

Self employed - Consultant

Brian Sutherland

Work:

University of Toronto

Brian Sutherland

Work:

Mixed Nuts Media

Brian Sutherland

Brian Sutherland

Brian Sutherland

view sourceFriends:

Cory Flaherty, Ashley Jeanne Long, Joey Keck, Alex William Jones, Brian Sutherland. Photo Log in to contact Brian Sutherland.

Brian Sutherland. Photo Log in to contact Brian Sutherland.

Brian Sutherland Nc

view source

Brian A Sutherland

view source

Brian Sutherland

view source

Brian Sutherland

view source

Brian M. Sutherland

view source

Brian Sutherland

view source

Brian Sutherland

view sourceFlickr

Get Report for Brian P Sutherland from Hampshire, IL, age ~44