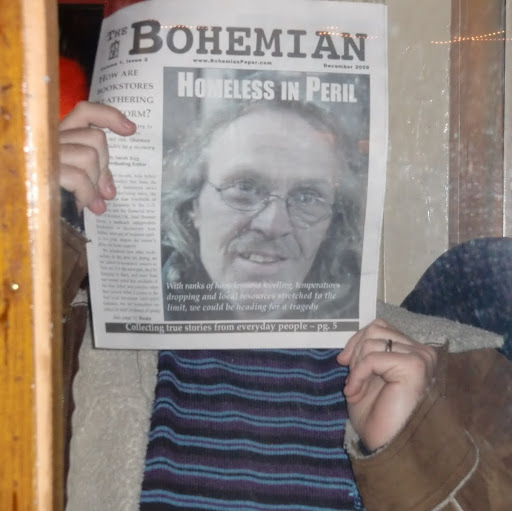

Daniel Corey Hendricks

age ~39

from Bremerton, WA

- Also known as:

-

- Daniel C Hendricks

- Corey Hendricks

- Daniel C Hendrick

- Phone and address:

- 2415 20Th St, Bremerton, WA 98312

Daniel Hendricks Phones & Addresses

- 2415 20Th St, Bremerton, WA 98312

- Moreno Valley, CA

- 1108 Oakhill St, Seffner, FL 33584

- Saint Petersburg, FL

- Tampa, FL

- Tulsa, OK

- Riverside, CA

Us Patents

-

Wireless Collection Of Fastener Data

view source -

US Patent:20110181393, Jul 28, 2011

-

Filed:Jan 22, 2010

-

Appl. No.:12/691796

-

Inventors:Brian J. Tillotson - Kent WA, US

Bradley J. Mitchell - Snchomish WA, US

Peter E. Herley - Renton WA, US

Brenda K. Carlson - Bothell WA, US

Kevin Y. Ung - Bellevue WA, US

Tamaira E. Ross - Seattle WA, US

Steven C. Venema - Kirkland WA, US

Kristina A. Chinn - Renton WA, US

James T. Farricker - North Bend WA, US

Daniel A. Hendricks - Kenmore WA, US

Richard R. Rocks - Spanoway WA, US

Charles B. Spinelli - Bainbaidge WA, US

David B. Blackwell - Seattle WA, US -

International Classification:H04Q 5/22

F16B 31/02 -

US Classification:340 101, 73761

-

Abstract:Data is remotely collected from a plurality of fasteners in response to a query signal wirelessly transmitted by a reader. Each of the fasteners includes a sensor for measuring a parameter related to the stress on the fastener. A device adapted to be attached to each of the fasteners receives the query signal, activates the sensor to measure the parameter and wirelessly transmits the data including the parameter to the reader.

-

Automatic Fastening Tool And Method Therefor

view source -

US Patent:57132500, Feb 3, 1998

-

Filed:Sep 26, 1996

-

Appl. No.:8/721388

-

Inventors:Daniel Albert Hendricks - Bothell WA

Arlen Ray Pumphrey - Arlington WA

Robert Stephen Schempp - Bothell WA -

Assignee:The Boeing Company - Seattle WA

-

International Classification:B25B 2100

-

US Classification:81 54

-

Abstract:Apparatus for assembling fasteners includes a fastening wrench operated by a first operator and having interchangeable sockets of different sizes for engaging nuts of different sizes. The nuts are required to be tightened to different torque values on their respective bolts. When the first operator removes a socket from a socket tray in preparation for attaching the socket to the fastening wrench, a signal is sent to a controller which determines the torque value associated with that socket size. When the fastening wrench reaches the specified torque value during the tightening operation, the controller automatically shuts the fastening wrench off. The apparatus also includes a second wrench, operated by a second operator, for engaging the heads of the bolts to prevent them from turning during the tightening process. During the tightening process the second operator may not be in communication with the first operator. The second wrench includes a safety switch which when not depressed by the second operator, prevents the fastening wrench from operating for the protection of the second operator.

-

Device For Orienting And Conveying A Headed Fastener

view source -

US Patent:47004711, Oct 20, 1987

-

Filed:Nov 14, 1985

-

Appl. No.:6/797962

-

Inventors:Paul J. Shemeta - Seattle WA

Daniel A. Hendricks - Bothell WA -

Assignee:The Boeing Company - Seattle WA

-

International Classification:B23Q 710

B23Q 712

B65H 900 -

US Classification:29809

-

Abstract:Disclosed is device (10) for orienting and conveying a headed fastener (14), wherein the device is positioned beneath any suitable dispenser (12) whereby headed fasteners are removed from a supply container and successively dropped with random orientation onto the device. The device (10) is configured to receive the headed fasteners (14) within a selected groove (32, 132) so that the headed fastener will assume a predetermined orientation within the device. The oriented fastener is then conveyed from the point it is received in the groove to a conduit (55, 57) which directs the headed fastener into the feeder tube (16) of the fastening machine. The fasteners are rotated as they are conveyed along the device in order to create a gyroscopic effect in the fastener as a means of maintaining the relative orientation of the fastener as it moves through the groove toward the feeder tube.

-

Hand Tool For Installing Plastic Fasteners

view source -

US Patent:46533095, Mar 31, 1987

-

Filed:Jan 7, 1986

-

Appl. No.:6/816904

-

Inventors:Daniel A. Hendricks - Bothell WA

Warren E. Townsend - Seattle WA -

Assignee:The Boeing Company - Seattle WA

-

International Classification:B21B 3100

-

US Classification:72391

-

Abstract:One end of a pull rod (66) is pivotably attached to a lever (82), and the other end of rod (66) has a T-shaped slot (70) for receiving the head (28) and part of the shaft (24) of a plastic blind rivet fastener (22). Rod (66) slides axially in a tube (54) which has a radial end wall (60) with a slot (62) for slidably receiving the shaft (24). A spring (76) biases the rod (66) into a fastener-receiving position adjacent to wall (60). The lever (82) is squeezed toward a handle (56) to pull the rod (66) away from the wall (60) and the fastener head (28) axially inwardly. The abutment of the wall (60) against a collar (36) on shaft (24) slides collar (36) along shaft (24) to force a portion of a sleeve (30) on shaft (24) radially outwardly. A bent tube (104) may be provided instead of the straight tube (54). The pull member (110) received in the tube (104) has two rod portions (112,120) on oposite sides of the bend (106).

-

Quick Change Drill Chuck Systems

view source -

US Patent:47431458, May 10, 1988

-

Filed:Nov 26, 1986

-

Appl. No.:6/935370

-

Inventors:Daniel A. Hendricks - Bothell WA

Paul J. Shemeta - Seattle WA -

Assignee:The Boeing Company - Seattle WA

-

International Classification:B23B 4514

B23Q 1110 -

US Classification:408 59

-

Abstract:Quick change chuck systems with integral fluid inducer. A quick change drill bushing system reduces misalignment of bushing to motor spindles and enables rapid change of cutting tools and bushing thereby reducing the number of dedicated working systems. The quick change chuck system with integral fluid inducer may utilize a quick change nosepiece system in combination.

-

Quick Change Drill Chuck Systems

view source -

US Patent:47493160, Jun 7, 1988

-

Filed:Nov 26, 1986

-

Appl. No.:6/935371

-

Inventors:Daniel A. Hendricks - Bothell WA

-

Assignee:The Boeing Company - Seattle WA

-

International Classification:B23B 4514

B23Q 1110 -

US Classification:408239R

-

Abstract:Quick change chuck systems with integral fluid inducer. A quick change drill bushing system reduces misalignment of bushing to motor spindles and enables rapid change of cutting tools and bushing thereby reducing the number of dedicated working systems. The quick change chuck system with integral fluid inducer may utilize a quick change nosepiece system in combination.

Name / Title

Company / Classification

Phones & Addresses

1ST CHOICE STAFFING SOLUTIONS, INC

Resumes

Lot Attendant

view sourceLocation:

337 northeast Fairgrounds Rd, Bremerton, WA 98311

Industry:

Automotive

Work:

Advantage Nissan

Lot Attendant

Manpower Mar 2014 - Apr 2014

Customer Service Representative

Pacific Fuels May 2012 - Dec 2013

Customer Service Representative

Olympic High School Student Store Feb 2010 - Jun 2011

Student Manager

Lot Attendant

Manpower Mar 2014 - Apr 2014

Customer Service Representative

Pacific Fuels May 2012 - Dec 2013

Customer Service Representative

Olympic High School Student Store Feb 2010 - Jun 2011

Student Manager

Education:

Olympic College 2011 - 2015

Olympic High School

Olympic High School

Skills:

Microsoft Office

Microsoft Excel

Microsoft Word

Microsoft Excel

Microsoft Word

President

view sourceWork:

President

Software Developer Ii

view sourceWork:

Software Developer Ii

Daniel Hendricks

view source

Daniel Hendricks

view sourceLocation:

United States

Daniel Hendricks

view sourceLocation:

United States

Daniel Hendricks

view sourceLocation:

United States

Medicine Doctors

Daniel E. Hendricks

view sourceSpecialties:

Diagnostic Radiology, Vascular & Interventional Rad

Work:

Corvallis Radiology PC

525 N Santiam Hwy, Lebanon, OR 97355

5417585047 (phone), 5417583713 (fax)

Corvallis Radiology

3600 NW Samaritan Dr, Corvallis, OR 97330

5417585047 (phone), 5417583713 (fax)

East Linn MRI

505 N Santiam Hwy, Lebanon, OR 97355

5414516950 (phone), 5414516953 (fax)

Corvallis MRI A Joint Venture

3615 NW Samaritan Dr, Corvallis, OR 97330

5417685187 (phone), 5417685092 (fax)

525 N Santiam Hwy, Lebanon, OR 97355

5417585047 (phone), 5417583713 (fax)

Corvallis Radiology

3600 NW Samaritan Dr, Corvallis, OR 97330

5417585047 (phone), 5417583713 (fax)

East Linn MRI

505 N Santiam Hwy, Lebanon, OR 97355

5414516950 (phone), 5414516953 (fax)

Corvallis MRI A Joint Venture

3615 NW Samaritan Dr, Corvallis, OR 97330

5417685187 (phone), 5417685092 (fax)

Education:

Medical School

University of Virginia School of Medicine

Graduated: 2003

University of Virginia School of Medicine

Graduated: 2003

Languages:

English

Description:

Dr. Hendricks graduated from the University of Virginia School of Medicine in 2003. He works in Corvallis, OR and 3 other locations and specializes in Diagnostic Radiology and Vascular & Interventional Rad. Dr. Hendricks is affiliated with Good Samaritan Regional Medical Center, Samaritan Lebanon Community Hospital and Samaritan North Lincoln Hospital.

Daniel Ewell Hendricks

view sourceSpecialties:

Surgery

Thoracic Surgery

Cardiothoracic Vascular Surgery

Thoracic Surgery

Cardiothoracic Vascular Surgery

Education:

University of Virginia (1957)

License Records

Daniel K Hendricks

License #:

11359 - Expired

Category:

Emergency Medical Care

Issued Date:

Dec 31, 1995

Effective Date:

Jan 5, 2011

Expiration Date:

Dec 31, 2010

Type:

EMT

Daniel K Hendricks

License #:

4211 - Expired

Category:

Emergency Medical Care

Issued Date:

Dec 31, 1995

Effective Date:

Mar 8, 1999

Type:

EMT A/D

Classmates

Daniel Hendricks

view sourceSchools:

Queen of Apostles High School Madison WI 1960-1964

Community:

Shelly Finn, Bill Berge, Jeffrey Romnes, Julia Sarbacker, Sally Adebayo, Dennis Meyer

Daniel Hendricks

view sourceSchools:

New Hope-Solebury High School New Hope PA 1948-1952

Community:

Robin Pinero, Kevin Mckeever, Robert Proctor

Daniel Hendricks

view sourceSchools:

Jewett-Scio High School Scio OH 1983-1987

Community:

Aimee Gauker, Lois Emery

Daniel Hendricks

view sourceSchools:

The Center School Highland Park NJ 1993-1997

Community:

Christopher Clark, James Mcgowan, Monel Walker

Daniel Hendricks | West N...

view source

Daniel Hendricks, Merkel ...

view source

Daniel Hendricks | Spring...

view source

Daniel Hendricks | Mt. Ca...

view sourceYoutube

Daniel Hendricks

view source

Daniel Hendricks

view source

Daniel Hendricks

view source

Daniel Hendricks

view source

Daniel Hendricks

view source

Daniel Hendricks

view source

Daniel Hendricks

view source

Daniel Nathan Hendricks

view sourceMyspace

Googleplus

Daniel Hendricks

Work:

Wal-Mart - Electronics Sales Associate (2009)

Chattanooga Times Free Press - Graphic Designer (2008-2008)

Ann Arbor News - Inserter (2005-2008)

Chattanooga Times Free Press - Graphic Designer (2008-2008)

Ann Arbor News - Inserter (2005-2008)

Education:

Cleveland State Community COllege, Western Governors University, Washtenaw Community College - Graphic Design, Wasthenaw Technical Middle College - High School

Daniel Hendricks

Education:

Olympic College - Engineering, Olympic High School - High School

Tagline:

I reject your reality, and substitute my own.

Daniel Hendricks

Work:

FedEx - Courier (2010)

Daniel Hendricks

Tagline:

Yet another Social Network.... anyone on here that doesn't work for Google?

Daniel Hendricks

Daniel Hendricks

Daniel Hendricks

Daniel Hendricks

Get Report for Daniel Corey Hendricks from Bremerton, WA, age ~39