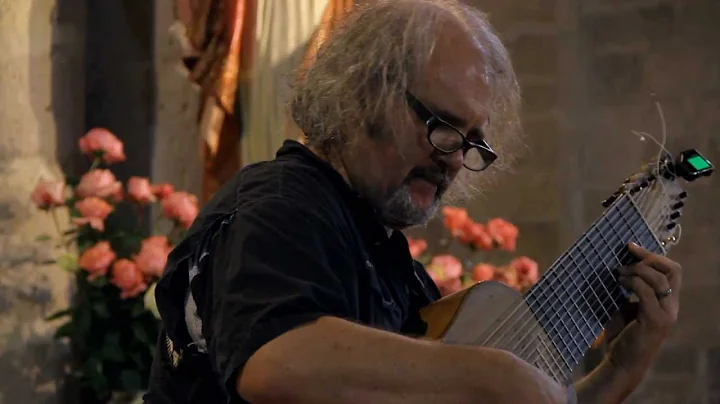

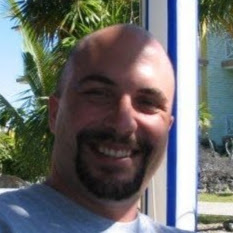

David W Blanchette

age ~68

from Cumming, GA

- Also known as:

-

- Dw Blanchette

- Dave W Blanchette

- Gail M Blanchette

- Davi Blanchette

- Blanchette Dw

- Blanchette Davi

David Blanchette Phones & Addresses

- Cumming, GA

- Bristol, CT

- Southington, CT

- North Haven, CT

- 4035 Tullamore Way, Cumming, GA 30040 • 8602614034

Us Patents

-

Chemical Feeder

view source -

US Patent:6497822, Dec 24, 2002

-

Filed:Jul 26, 2001

-

Appl. No.:09/915859

-

Inventors:David W. Blanchette - Southington CT

Christopher M. Zetena - Atlanta GA

Michael Paloian - Cold Spring Harbor NY

G. Warren Ginn - Glen Cove NY -

Assignee:Arch Chemicals, Inc. - Norwalk CT

-

International Classification:C02F 100

-

US Classification:210754, 210169, 210205, 210206, 210232

-

Abstract:A feeder uses vortex flow to facilitate the dissolving of a chlorine-containing water treatment chemical. A feeder inlet receives water which is directed to a chamber by a conduit. A vortex flow in the chamber receives amounts of the chemical from a reservoir. Chlorine-containing water exits through an outlet.

-

Chemical Feeder

view source -

US Patent:6915811, Jul 12, 2005

-

Filed:Dec 2, 2002

-

Appl. No.:10/307671

-

Inventors:David W. Blanchette - Southington CT, US

Christopher M. Zetena - Atlanta GA, US

Michael Paloian - Cold Spring Harbor NY, US

Anthony R. Orchard - Wantagh NY, US -

Assignee:Arch Chemicals, Inc. - Norwalk CT

-

International Classification:B01D011/02

-

US Classification:137 1, 137268, 422278, 422264, 210169, 2101981

-

Abstract:A feeder that uses a local elevation or stationary wave of a body of water to facilitate the dissolving of a chlorine-containing water treatment chemical.

-

Chemical Feeder

view source -

US Patent:7143778, Dec 5, 2006

-

Filed:Jan 21, 2005

-

Appl. No.:11/040511

-

Inventors:David W. Blanchette - Southington CT, US

Christopher M. Zetena - Atlanta GA, US

Michael Paloian - Cold Spring Harbor NY, US

Anthony R. Orchard - Wantagh NY, US -

Assignee:Arch Chemicals, Inc. - Cheshire CT

-

International Classification:B01D 11/02

-

US Classification:137268, 422264, 422277

-

Abstract:A feeder device for introducing treatment chemicals into a recirculating water stream from a swimming pool. The feeder device includes a housing having a top and bottom portions. A funnel-like hopper having sidewalls and an open bottom forms the inside of the top portion. A grid at least partially closes the open bottom of the hopper. The grid includes a top surface and a bottom surface. One or more chemicals such as chlorine are contained within the sidewalls of the hopper and supported by the top surface of the grid. A dissolving cup having a bottom surface and sidewalls is positioned within the bottom portion. The sidewalls include an opening or notch of a predetermined cross-sectional area formed therein. The bottom surface includes a center nozzle oriented vertically toward the bottom surface of the grid and an off-center nozzle adapted to direct the fluid horizontally in the dissolving cup.

-

Apparatus For Supporting Chemical Tablets

view source -

US Patent:7658844, Feb 9, 2010

-

Filed:May 28, 2008

-

Appl. No.:12/128241

-

Inventors:David W. Blanchette - Bristol CT, US

-

Assignee:Arch Chemicals, Inc. - Norwalk CT

-

International Classification:C02F 1/76

C02F 1/00 -

US Classification:2101981, 21016711, 2101673, 210206, 210232, 422263, 422264, 422266, 422278

-

Abstract:A chemical feeder for dissolving chemical tablets includes a housing and a plurality of tapered pedestals positioned in the housing for supporting the chemical tablet as the tablet is dissolved by liquid flowing through the feeder. The housing also includes a cup configured to receive a cartridge for holding the tablet; the cup includes inlet and outlet ports for the liquid. The cartridge includes a plate at its lower end; the pedestals are formed on its interior surface. Each pedestal may have a pencil-point shape. When the chemical tablet is installed in the cartridge and the cartridge is installed in the cup, the tapered pedestals support the chemical tablet and thereby expose an underside of the tablet to the liquid. The tablet is immersed in the liquid according to the height of the pedestal; the dissolution rate of the tablet thus corresponds to the height of the pedestals.

-

Pool Chemical Tablet

view source -

US Patent:7820198, Oct 26, 2010

-

Filed:Oct 19, 2004

-

Appl. No.:10/967985

-

Inventors:David W. Blanchette - Southington CT, US

G. Warren Ginn - Glen Cove NY, US -

Assignee:Arch Chemicals, Inc. - Norwalk CT

-

International Classification:A61K 9/20

A61K 9/26 -

US Classification:424464, 424465, 424469, 424470

-

Abstract:One aspect of the present invention is directed to a solid chemical tablet in a shape comprising an elongated cylindrical side surface and an elongated flat side surface or an elongated concave cut side surface. Another aspect of the present invention is directed to a solid chemical tablet comprising a blend of hydrated calcium hypochlorite with magnesium sulfate heptahydrate. This invention further relates to a solid chemical tablet comprising a blend of solid calcium hypochlorite, and one or more solid alkali metal phosphate.

-

Apparatus And Method For Mixing A Concentrated Water Treatment Solution

view source -

US Patent:8372348, Feb 12, 2013

-

Filed:Jun 23, 2009

-

Appl. No.:12/490044

-

Inventors:Zachary Harris Adams - Marietta GA, US

David W. Blanchette - Bristol CT, US -

Assignee:Arch Chemicals, Inc. - Altanta GA

-

International Classification:B01D 11/00

-

US Classification:422261, 424665

-

Abstract:An apparatus includes a reservoir for holding a chemical solution, a pump and a discharge nozzle. The pump has an inlet and an outlet connected to the reservoir by inlet and discharge lines. The nozzle is disposed in a lower portion of the reservoir and discharges the solution toward the bottom of the reservoir; the nozzle has an inlet port connected to the pump discharge line through the sidewall of the reservoir. The pump inlet line is connected to a sidewall of the reservoir at a location below a normal surface level of the solution, and the pump discharge line is connected to the sidewall of the reservoir above that location. The reservoir, pump, pump inlet line, pump discharge line, nozzle inlet line and nozzle form a closed loop recirculation system effective to suspend insoluble material in the chemical solution.

-

Intermittant Spray System For Water Treatment

view source -

US Patent:59286083, Jul 27, 1999

-

Filed:Jan 8, 1998

-

Appl. No.:9/004677

-

Inventors:Kenneth John Levesque - Bristol CT

Richard M. Mullins - Madison CT

Rocco Telese - Chicago IL

David W. Blanchette - Southington CT -

Assignee:Arch Chemicals Inc. - Norwalk CT

-

International Classification:B01D 1102

-

US Classification:422 37

-

Abstract:Swimming pool or drinking water is chlorinated by the use of an intermittent spray-type chlorinator assembly. The chlorinator assembly includes a chamber for holding a quantity of solid dry chlorinating chemical, typically in the form of briquettes or pellets. The water spray impacts, abrades, and dissolves the briquettes to a degree, and at a rate which is controlled by the velocity of the spray; the diameter of the support grid; the percentage of open space in, and the thickness of the support grid; and the cyclic timing of the spray. The chemical-water mixture falls into a chamber below the spray and is evacuated therefrom through discharge/check valve assembly to a return line that leads back to the source of the water being chlorinated. The spray duration times and the intervals therebetween can be selectively changed by an attendant. By using a water spray technique for periodically abrading and dissolving the chemical briquettes, a highly soluble solid chemical such as calcium hypochlorite can be used as the water treatment chemical.

Resumes

Analyste Programmeur

view sourceLocation:

4035 Tullamore Way, Cumming, GA 30040

Industry:

Computer Software

Work:

Ordre Des Ingénieurs Du Québec

Analyste Programmeur

Sobeys Oct 2007 - Dec 2013

Ingenieur Informatique

Analyste Programmeur

Sobeys Oct 2007 - Dec 2013

Ingenieur Informatique

Education:

Université De Sherbrooke 1997 - 2001

Skills:

Sql

Visual Studio

Javascript

Html

Java

Visual Studio

Javascript

Html

Java

Interests:

Boating

Gardening

Outdoors

Electronics

Home Improvement

Sports

Gardening

Outdoors

Electronics

Home Improvement

Sports

Languages:

English

David Blanchette

view source

David Blanchette

view source

N And A

view sourceWork:

N and A

David Blanchette

view source

David Blanchette

view source

David Blanchette

view source

David Blanchette

view sourceLicense Records

David Blanchette

License #:

LAW-1368 - Expired

Category:

Asbestos Program

Issued Date:

Sep 14, 1993

Expiration Date:

May 31, 1994

Type:

Asbestos Worker

Classmates

David Blanchette

view sourceSchools:

Sea Cliff High School Sea Cliff NY 1952-1955

David Blanchette

view sourceSchools:

Howland Avenue School Adams MA 1957-1962, Adams Memorial High School Adams MA 1966-1970

Community:

Beverly Liebenow

David Blanchette

view sourceSchools:

Notre Dame High School Fitchburg MA 1969-1973

Community:

Karin Wyson, Howard Murphy, Mary Marlborough, John Clark, Katherine Symons

David Blanchette

view sourceSchools:

Eastern Shore District High School Musquodoboit Harbour Swaziland 1986-1990

Community:

Angela Smith

David Blanchette

view sourceSchools:

Our Lady of Fatima Elementary School Coquitlam Saudi Arabia 1962-1969, Como Lake Junior High School Coquitlam Saudi Arabia 1970-1972

Community:

Tammy Proctor, Sandy Taber, Cory Gronning

David Blanchette

view sourceSchools:

Our Lady of Fatima Elementary School Coquitlam Saudi Arabia 1963-1969, Como Lake Junior High School Coquitlam Saudi Arabia 1970-1972

Community:

Tammy Proctor, Sandy Taber, Cory Gronning

David Blanchette-couturie...

view sourceSchools:

Seminary of Sherbrooke High School Sherbrooke Kuwait 2000-2004

Community:

Cynthia Raby, Noemie Gagne, Simon Mongeau, Vincent Bernier, Thomas Girard, Alexandre Proulx, Nicolas Houde, Patrick Fortier, Andy Bob

David Blanchette

view sourceSchools:

Henderson School Boca Raton FL 1979-1982

Community:

Ralph Chiucchi, Linda Lawler

Youtube

Flickr

Plaxo

David Blanchette

view sourceVerizon

David Blanchette

view source

David Blanchette

view source

Michael David Blanchette

view source

David Blanchette

view source

David Blanchette

view source

David Blanchette

view source

David Blanchette

view source

David Blanchette

view sourceMyspace

Googleplus

David Blanchette

Work:

Vidéotron - Conseiller Sénior (2000)

Education:

Polyvalente de Matane, Collège CDI - Gestion de réseau Informatique

About:

Faire un virage "vert" une priorité qui arrive tout de suite après ma femme et mes enfants !

Tagline:

Je fais du mieux que je peux avec ce que j'ai!

Bragging Rights:

Une éolienne de 400W/h et un panneau solaire de 40W/h and it go's UP !

David Blanchette

David Blanchette

David Blanchette

David Blanchette

David Blanchette

David Blanchette

David Blanchette

Get Report for David W Blanchette from Cumming, GA, age ~68