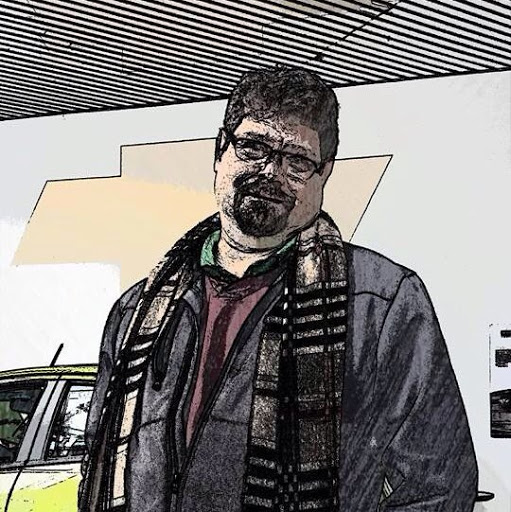

Dennis C Morrison

age ~55

from Lincolnton, NC

- Also known as:

-

- Denny C Morrison

- Phone and address:

-

4113 Stoney Creek Dr, Lincolnton, NC 28092

7042409981

Dennis Morrison Phones & Addresses

- 4113 Stoney Creek Dr, Lincolnton, NC 28092 • 7042409981

- Linthicum Heights, MD

- Baltimore, MD

- Glen Burnie, MD

- Linthicum Hts, MD

Work

-

Position:Professional/Technical

Vehicle Records

-

Dennis Morrison

view source -

Address:4113 Stoney Crk Dr, Lincolnton, NC 28092

-

VIN:1ZVFT85H275323183

-

Make:FORD

-

Model:MUSTANG

-

Year:2007

Medicine Doctors

Dennis N. Morrison

view sourceSpecialties:

Family Medicine

Work:

Ozarks Community Hospital Family Medicine

2828 N National Ave STE G, Springfield, MO 65803

4178744510 (phone), 4178754720 (fax)

2828 N National Ave STE G, Springfield, MO 65803

4178744510 (phone), 4178754720 (fax)

Education:

Medical School

Kansas City University of Medicine and Biosciences College of Osteopathic Medicine

Graduated: 1976

Kansas City University of Medicine and Biosciences College of Osteopathic Medicine

Graduated: 1976

Procedures:

Arthrocentesis

Vaccine Administration

Osteopathic Manipulative Treatment

Vaccine Administration

Osteopathic Manipulative Treatment

Conditions:

Abnormal Vaginal Bleeding

Acne

Acute Conjunctivitis

Acute Sinusitis

Allergic Rhinitis

Acne

Acute Conjunctivitis

Acute Sinusitis

Allergic Rhinitis

Languages:

English

Description:

Dr. Morrison graduated from the Kansas City University of Medicine and Biosciences College of Osteopathic Medicine in 1976. He works in Springfield, MO and specializes in Family Medicine. Dr. Morrison is affiliated with Mercy Hospital Joplin and Ozarks Community Hospital.

License Records

Dennis Lee Morrison

License #:

70100119 - Active

Category:

EMS Licensing

Issued Date:

Jun 14, 2016

Expiration Date:

Jun 30, 2018

Type:

First Responder (EMR)

Name / Title

Company / Classification

Phones & Addresses

Co-Owner

Lawn Doctor

Small Engine Repair. Welding. Lawn Mowers - Sharpen & Repair. Generators

Small Engine Repair. Welding. Lawn Mowers - Sharpen & Repair. Generators

1432 Travis Rd, Conover, NC 28613

8284655439, 8284651981

8284655439, 8284651981

Owner

Doctor Lawnmower

Repair Services

Repair Services

1432 Travis Rd, Conover, NC 28613

Co-Owner

Lawn Doctor

Small Engine Repair · Welding · Lawn Mowers - Sharpen & Repair · Generators

Small Engine Repair · Welding · Lawn Mowers - Sharpen & Repair · Generators

1432 Travis Rd, Conover, NC 28613

8284655439, 8284651981

8284655439, 8284651981

FAIRBORN ALTERNATIVE MIDDLE SCHOOL, INC

Partner

PRICE WATERHOUSE LLP

S.I.S. PRODUCTIONS, INC

PRIMEAU CORPORATION, INC

DPE ENTERPRISES, INC

Us Patents

-

Fiber Optic Connector Sub-Assemblies And Fiber Optic Connectors Including The Same

view source -

US Patent:20190227243, Jul 25, 2019

-

Filed:Apr 3, 2019

-

Appl. No.:16/374011

-

Inventors:- Hickory NC, US

Rebecca Lynn Burt - Painted Post NY, US

Jeffrey Dean Danley - Hickory NC, US

Darrin Max Miller - Hickory NC, US

Dennis Craig Morrison - Lincolnton NC, US -

International Classification:G02B 6/38

C09J 161/02

C09J 171/08

C09J 179/08

C09J 181/04 -

Abstract:A fiber optic connector sub-assembly includes a ferrule having a front end, a rear end, and a ferrule bore extending between the front and rear ends along a longitudinal axis. The fiber optic connector sub-assembly also includes a bonding agent disposed in the ferrule bore and having first and second ends along the longitudinal axis. The bonding agent has been melted and solidified at the first and second ends without there being an optical fiber present in the ferrule bore.

-

Fiber Optic Connector Sub-Assemblies And Related Methods

view source -

US Patent:20180180821, Jun 28, 2018

-

Filed:Feb 21, 2018

-

Appl. No.:15/900876

-

Inventors:- Hickory NC, US

Darrin Max Miller - Hickory NC, US

Dennis Craig Morrison - Lincolnton NC, US -

International Classification:G02B 6/38

-

Abstract:A fiber optic connector sub-assembly includes a ferrule having a front end, a rear end, and a ferrule bore extending between the front and rear ends along a longitudinal axis. The ferrule bore has a first section extending inwardly from the rear end of the ferrule, a second section extending inwardly from the front end of the ferrule and having a width that is less than the first section, and a transition section located between the first and second sections. The fiber optic connector sub-assembly also includes a bonding agent disposed in at least a portion of both the transition section and the second section of the ferrule bore. At least some of the bonding agent in the second section of the ferrule bore has been melted and solidified.

-

Methods Of Making Fiber Optic Connector Sub-Assemblies

view source -

US Patent:20180180822, Jun 28, 2018

-

Filed:Feb 21, 2018

-

Appl. No.:15/900963

-

Inventors:- Hickory NC, US

Rebecca Lynn Burt - Painted Post NY, US

Jeffrey Dean Danley - Hickory NC, US

Darrin Max Miller - Hickory NC, US

Dennis Craig Morrison - Lincolnton NC, US -

International Classification:G02B 6/38

C09J 161/02

C09J 181/04

C09J 171/08

C09J 179/08 -

Abstract:A method of making a fiber optic connector sub-assembly involves: initially disposing a bonding agent in a ferrule bore of a ferrule; heating at least a portion of the ferrule above a melting temperature of the bonding agent so that some of the bonding agent melts; and solidifying the bonding agent that has melted to form the fiber optic connector sub-assembly, all without an optical fiber being disposed within the ferrule bore.

-

Methods Of Making Fiber Optic Connector Sub-Assemblies

view source -

US Patent:20180180823, Jun 28, 2018

-

Filed:Feb 21, 2018

-

Appl. No.:15/901151

-

Inventors:- Hickory NC, US

Rebecca Lynn Burt - Painted Post NY, US

Jeffrey Dean Danley - Hickory NC, US

Darrin Max Miller - Hickory NC, US

Dennis Craig Morrison - Lincolnton NC, US -

International Classification:G02B 6/38

C09J 181/04

C09J 161/02

C09J 171/08

C09J 179/08 -

Abstract:A method of making a fiber optic connector sub-assembly involves: initially disposing a bonding agent in a ferrule bore of a ferrule; heating at least a portion of the ferrule above a melting temperature of the bonding agent so that some of the bonding agent melts; and solidifying the bonding agent that has melted to form the fiber optic connector sub-assembly, all without an optical fiber being disposed within the ferrule bore.

-

Fiber Optic Connector Sub-Assemblies Including A Bonding Agent, Along With Related Methods

view source -

US Patent:20180059336, Mar 1, 2018

-

Filed:Aug 25, 2017

-

Appl. No.:15/686490

-

Inventors:- Hickory NC, US

Darrin Max Miller - Hickory NC, US

Dennis Craig Morrison - Lincolnton NC, US -

International Classification:G02B 6/38

-

Abstract:A fiber optic connector sub-assembly includes a ferrule having a front end, a rear end, and a ferrule bore extending between the front and rear ends along a longitudinal axis. The fiber optic connector sub-assembly also includes a bonding agent disposed in the ferrule bore and having first and second ends along the longitudinal axis. The bonding agent has been melted and solidified at the first and second ends.

-

Method Of Forming An Optical Connector

view source -

US Patent:20180052286, Feb 22, 2018

-

Filed:Oct 27, 2017

-

Appl. No.:15/795779

-

Inventors:- Hickroy NC, US

Darrin Max Miller - Hickory NC, US

Dennis Craig Morrison - Lincolnton NC, US -

International Classification:G02B 6/38

-

Abstract:A method of forming an optical fiber connector comprises preloading an adhesive plug into a ferrule bore of a ferrule. The ferrule bore extends between a first face and a second face of the ferrule and includes a large diameter bore section extending inwardly from the first face, a micro-hole section extending inwardly from the second face, and a transition section located between the large diameter bore section and the micro-hole section. The adhesive plug: a) is coupled to at least the transition section during the preloading, b) comprises an adhesive composition in a stable form, and c) blocks an entrance into the micro-hole section from the transition section. The method also comprises storing the adhesive plug in the ferrule bore for at least one day without coupling the optical connector to an optical fiber.

-

Method Of Forming An Optical Connector

view source -

US Patent:20170131484, May 11, 2017

-

Filed:Jan 25, 2017

-

Appl. No.:15/414840

-

Inventors:- Hickory NC, US

Darrin Max Miller - Hickory NC, US

Dennis Craig Morrison - Lincolnton NC, US -

International Classification:G02B 6/38

-

Abstract:A method of forming an optical fiber connector is provided. The optical connector includes a body having a passage with a first section extending inwardly from a first face of the body, a second section extending inwardly from a second face from the body, and a transition section located between the first and second sections. The first section of the passage has a first width and the second section of the passage has a second width that is less than the first width. The method comprises loading an adhesive composition into the passage and storing the adhesive composition for at least one day without coupling the optical connector to an optical fiber. The adhesive composition is a meltable, substantially solid material maintained the first passage section, transition section, or both the second passage section and transition section.

-

Fiber Optic Connector Sub-Assemblies And Related Methods

view source -

US Patent:20170052328, Feb 23, 2017

-

Filed:Oct 19, 2015

-

Appl. No.:14/886905

-

Inventors:- Hickory NC, US

Rebecca Lynn Burt - Painted Post NY, US

Jeffrey Dean Danley - Hickory NC, US

Darrin Max Miller - Hickory NC, US

Dennis Craig Morrison - Lincolnton NC, US -

International Classification:G02B 6/38

C09J 161/02

C09J 179/08

C09J 181/04

C09J 171/08 -

Abstract:A fiber optic connector sub-assembly includes a ferrule having a front end, a rear end, and a ferrule bore extending between the front and rear ends along a longitudinal axis. The fiber optic connector sub-assembly also includes a bonding agent disposed in the ferrule bore and having first and second ends along the longitudinal axis. The bonding agent has been melted and solidified at the first and second ends.

Youtube

Myspace

Flickr

Plaxo

Dennis Morrison, PhD

view sourceBloomington, INCEO at Centerstone Research Institute Past: CEO at Center for Behavioral Health

Dennis Morrison

view sourceLondon, United Kingdom

Dennis Morrison

view source

Dennis Morrison

view sourceFrontier Kemper

Classmates

Dennis Morrison

view sourceSchools:

Memorial Elementary School New Gloucester ME 1990-1994

Community:

Dennis Brackley, Danielle Plante, Norman Sybert

Dennis Morrison

view sourceSchools:

Charleston Catholic High School Charleston WV 1962-1966

Community:

Richard Norcross, Catherine Kee, Joyce Guinn, Gary Jarrell, Patrick Parker, Dan Moriarty

Dennis Morrison

view sourceSchools:

St. Viator High School Arlington Heights IL 1978-1982

Community:

Todd Harris, Anthony Russo, Lisa Jarolin, Karie Kordick

Dennis Morrison

view sourceSchools:

Hot Springs High School Hot Springs AR 1964-1968

Community:

Marilynne Murray, Tommy Parsons

Dennis Morrison

view sourceSchools:

Mexico High School Mexico NY 1985-1989, Lowville Academy Lowville NY 1987-1989

Community:

Anita Miuccio

Dennis Morrison

view sourceSchools:

Sleepy Hollow High School North Tarrytown NY 1983-1987

Community:

Medard Lizotte, Albert Butkovich

Dennis Morrison

view sourceSchools:

Oil City High School Oil City PA 1958-1962

Community:

Anthony Lange, James Nichols, Benny Esparza, William Fillgrove

Dennis Morrison

view sourceSchools:

Clarenceville High School Livonia MI 1973-1977

Community:

Ray Smith, Mary Flores

Googleplus

Dennis Morrison

About:

I'm the author of 'Online Video Success Toolkit - Use video to capture and keep your audience'

Tagline:

Creative Technologist

Dennis Morrison

Dennis Morrison

Dennis Morrison

Dennis Morrison

Dennis Morrison

Dennis Morrison

Dennis Morrison

Dennis Bear Morrison

view source

Dennis Gary Morrison

view source

Dennis Morrison

view source

Dennis Morrison

view source

Dennis Nathaniel Morrison

view source

Dennis Morrison Morrison

view source

Dennis Nhyira Morrison

view source

Dennis Wayne Morrison

view sourceGet Report for Dennis C Morrison from Lincolnton, NC, age ~55