Douglas B Snell

age ~57

from South Portland, ME

- Also known as:

-

- Douglas Brian Snell

- Doug B Snell

- Douglas Shell

Douglas Snell Phones & Addresses

- South Portland, ME

- 10700 W 124Th St, Overland Park, KS 66213 • 9782703919

- Olathe, KS

- 3370 Lafayette Rd, Portsmouth, NH 03801

- Rotonda West, FL

- Amesbury, MA

- East Wakefield, NH

- Lynchburg, VA

- Forest, VA

- 214 Elwyn Ave, Portsmouth, NH 03801 • 9783883724

Work

-

Company:Happe spineFeb 2018

-

Position:Engineering and program director

Education

-

Degree:Bachelors, Bachelor of Science

-

School / High School:University of Maine1986 to 1991

-

Specialities:Mechanical Engineering

Skills

Medical Devices • Iso 13485 • Product Development • Fda • Design Control • Product Design • R&D • Orthopedic • V&V • Design For Manufacturing • Solidworks • Product Launch • Engineering • Project Management • Pro Engineer • Biomedical Engineering • Commercialization • Cross Functional Team Leadership • Quality System • Orthopedics • Design of Experiments • Iso • Mechanical Engineering • Validation • Biomaterials • Innovation Development • Arthroscopy • Minimally Invasive Procedures • Gd&T • Surgical Instruments • U.s. Food and Drug Administration • Implants • Iso 14971 • Quality Auditing • Working With Surgeons

Languages

English • French

Interests

Endurance Sports • Travel • Skiing • Sailing

Industries

Medical Devices

Us Patents

-

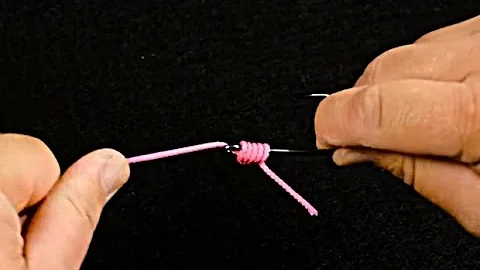

Heater Assembly For Suture Welder

view source -

US Patent:8592730, Nov 26, 2013

-

Filed:Dec 19, 2007

-

Appl. No.:11/959882

-

Inventors:Douglas Snell - Amesbury MA, US

Francis P. Harrington - Peabody MA, US

Paul Westhaver - Dartmouth, CA

Tom David Marro - Magnolia MA, US

Paul Schmitt - North Andover MA, US -

Assignee:Tomier, Inc. - Bloomington MN

-

International Classification:H05B 1/02

-

US Classification:219497, 219494, 219505, 219541, 219543, 219546

-

Abstract:Disclosed is a heater device for thermally welding suture strands, including: a substrate extending from a first end to a second end along a substrate axis, and having a substantially planar heater support surface; a joinder layer disposed on the heater support surface; a heater element extending from a first end to a second end along a heater axis thereof and disposed on the joinder layer, the heater element being a layer and being coupled to the support surface by the joinder layer; an electrical interface including a first electrically conductive element coupled to the first end of the heater element, and a second electrically conductive element coupled to the second end of the heater element. In some embodiments, the heater element is elongated along the heater axis.

-

Personal Floatation Device For Infant

view source -

US Patent:20050101202, May 12, 2005

-

Filed:Sep 16, 2004

-

Appl. No.:10/942190

-

Inventors:Douglas Snell - Amesbury MA, US

-

International Classification:B63C009/06

-

US Classification:441087000

-

Abstract:A personal floatation device to be used with an infant safety seat to provide a proper fitting, self-righting device to comply with USCG safety requirements. The device includes a floatation ring adaptable to encircle and securely attach to the infant safety seat by means of one or more capture straps and one or more retention straps. The floatation ring provides sufficient floatation to maintain the occupant airway above the water surface when floating in the water. The device further includes a righting means, which provides buoyancy-righting capability should the seat become inverted in the water. The righting strap helps secure the floatation ring to the infant safety seat.

-

Thermal Suture Welding Apparatus And Method

view source -

US Patent:20090182353, Jul 16, 2009

-

Filed:Aug 15, 2008

-

Appl. No.:12/192758

-

Inventors:Douglas Snell - Amesbury MA, US

Keith Boudreau - Beverly MA, US

Daniel McCormick - Westford MA, US

Dan Morgan - Salem MA, US

Francis P. Harrington - Peabody MA, US

Paul Westhaver - Dartmouth, CA

David Marro - Magnolia MA, US

John Yannone - Seabrook NH, US

Philip Hui - Boston MA, US

Thomas Egan - Marblehead MA, US -

International Classification:A61B 17/10

-

US Classification:606144, 606139

-

Abstract:A method of suture welding is disclosed which includes: receiving suture segments between first and second jaw members, the first and second jaw members being in an open state. closing the first and second jaw members to captively hold and position the suture segments between the first and second jaw members; selectively applying an elongated joiner element to the suture segments where the joiner element has a selectively operative heating element facing the suture segments; and applying energy to the heating element to weld the suture segments-to-be-welded, whereby the heating element has a temperature above a predetermined threshold adapted to at least partially melt the suture segments.

-

Sub-Cortical Suture Cutter

view source -

US Patent:20120136378, May 31, 2012

-

Filed:May 31, 2011

-

Appl. No.:13/149214

-

Inventors:Douglas B. SNELL - Amesbury MA, US

Daniel E. MORGAN - Salem MA, US -

International Classification:A61B 17/04

-

US Classification:606148

-

Abstract:An arthroscopic suture cutting device according to embodiments of the invention includes an outer tube; an inner rod including an outer surface and an aperture, a distalmost edge of a second distal opening located distally of a distalmost edge of a first distal opening, the inner rod can receive a suture extending through both distal openings; in a loading position, the inner rod extends distally of the outer tube to receive the suture; in an intermediate position, the distal openings are closer to the outer tube, such that the suture is permitted to slide through the aperture without release; and in a cut position, the distalmost edges of the distal openings are within the outer tube. Moving from intermediate position to cut position draws the suture between outer tube and inner rod, urging the inner rod radially toward the second distal opening, cutting the suture between the outer tube and the distalmost edge of the second distal opening.

-

Implant Delivery Device

view source -

US Patent:20220249250, Aug 11, 2022

-

Filed:Feb 28, 2022

-

Appl. No.:17/682748

-

Inventors:- Norfolk VA, US

Robert J. Ball - West Olive MI, US

Douglas Snell - Overland Park KS, US

Isaac Running - Bozeman MT, US

Christopher K. Jones - Colorado Springs CO, US

Brandon Bryant - Vienna VA, US -

International Classification:A61F 2/46

A61B 17/34 -

Abstract:An implant delivery device may include an implant holding portion proximate the distal end, the implant holding portion being configured to retain a sheet-like implant during implantation of the implant. In addition, the implant holding portion may be configured to receive the implant with a fixed implant supporting flange member configured to support the implant on one side, and a movable implant supporting flange member. The movable implant supporting flange member may be configured to be slidable between a distal position and a proximal position, wherein, in the distal position, the movable implant supporting flange member and secures the implant against the fixed implant supporting flange member, and in the proximal position, the movable implant supporting flange member is withdrawn from the distal end of the implant delivery device, thus enabling release of the implant.

-

Locking System For Interspinous Implant Insertion Instrument

view source -

US Patent:20220226026, Jul 21, 2022

-

Filed:Apr 8, 2022

-

Appl. No.:17/716813

-

Inventors:- Overland Park KS, US

Douglas Snell - Portland ME, US

Annaria Barnds - Roeland Park KS, US

Melissa Frock - Lenexa KS, US -

International Classification:A61B 17/70

A61F 2/46 -

Abstract:An insertion instrument for inserting an implant includes an elongated main body having a proximal handle and a distal portion that selectively couples to the implant. A plunger is slidably engaged in a central passage of the elongated main body to fix the implant to the elongated main body. A hex nut driver is concentrically located about the plunger and elongated main body to deploy an actuation plunger of the implant. The proximal handle portion of the main body includes a staggered path therethrough for accepting a tab of the plunger therein. Advancement and retraction of the plunger tab within the staggered path alternates the insertion instrument between an unlocked position to mount the implant on the distal portion, a locked position to lock the implant on the distal portion, and a deployed position configured to secure the implant in position.

-

Interspinous Implant Insertion Instrument With Wing Actuation Tool

view source -

US Patent:20220226027, Jul 21, 2022

-

Filed:Apr 8, 2022

-

Appl. No.:17/716822

-

Inventors:- Overland Park KS, US

Douglas Snell - Portland ME, US

Annaria Barnds - Roeland Park KS, US

Adam Frock - Lenexa KS, US

Jeffrey David Lee - Prairie Village KS, US

Jeff Slover - Lee's Summit MO, US -

International Classification:A61B 17/70

A61F 2/46 -

Abstract:An insertion instrument for inserting an implant includes an elongated main body having a proximal handle and a distal portion that selectively couples to the implant. A wing actuation tool is slidably engaged in a central passage of the elongated main body to fix the implant to the elongated main body. The wing actuation tool temporarily attaches to the implant allowing for deployment and retraction of wings of the implant during surgery. Longitudinal translation of the wing actuation tool deploys an actuation plunger of the implant.

-

Implantable Medical Device With Varied Composition And Porosity, And Method For Forming Same

view source -

US Patent:20230089343, Mar 23, 2023

-

Filed:Jul 22, 2022

-

Appl. No.:17/870911

-

Inventors:- Grand Rapids MI, US

Kevin Lee BROWN - Fort Wayne IN, US

Douglas B. SNELL - Overland Park KS, US

Ryan K. ROEDER - Granger IN, US

Mark G. MESSMAN - Larwill IN, US -

Assignee:HAPPE SPINE LLC - Grand Rapids MI

-

International Classification:B29C 43/00

A61F 2/28

A61F 2/30 -

Abstract:A method for forming a thermoplastic body having regions with varied material composition and/or porosity. Powder blends comprising a thermoplastic polymer, a sacrificial porogen and an inorganic reinforcement or filler are molded to form complementary parts with closely toleranced mating surfaces. The parts are formed discretely, assembled and compression molded to provide a unitary article that is free from discernible boundaries between the assembled parts. Each part in the assembly has differences in composition and/or porosity, and the assembly has accurate physical features throughout the sections of the formed article, without distortion and nonuniformities caused by variable compaction and densification rates in methods that involve compression molding powder blends in a single step.

Resumes

Engineering And Program Director

view sourceLocation:

21 Water St, Amesbury, MA 01913

Industry:

Medical Devices

Work:

Happe Spine

Engineering and Program Director

Genesis Innovation Group

Engineering and Program Director

Spinal Simplicity Jan 2016 - Feb 2018

Interim Director of Quality and Regulatory

Spinal Simplicity Jun 2015 - Feb 2018

Director of Engineering

Makhaira Jun 2015 - Feb 2018

Owner

Engineering and Program Director

Genesis Innovation Group

Engineering and Program Director

Spinal Simplicity Jan 2016 - Feb 2018

Interim Director of Quality and Regulatory

Spinal Simplicity Jun 2015 - Feb 2018

Director of Engineering

Makhaira Jun 2015 - Feb 2018

Owner

Education:

University of Maine 1986 - 1991

Bachelors, Bachelor of Science, Mechanical Engineering

Bachelors, Bachelor of Science, Mechanical Engineering

Skills:

Medical Devices

Iso 13485

Product Development

Fda

Design Control

Product Design

R&D

Orthopedic

V&V

Design For Manufacturing

Solidworks

Product Launch

Engineering

Project Management

Pro Engineer

Biomedical Engineering

Commercialization

Cross Functional Team Leadership

Quality System

Orthopedics

Design of Experiments

Iso

Mechanical Engineering

Validation

Biomaterials

Innovation Development

Arthroscopy

Minimally Invasive Procedures

Gd&T

Surgical Instruments

U.s. Food and Drug Administration

Implants

Iso 14971

Quality Auditing

Working With Surgeons

Iso 13485

Product Development

Fda

Design Control

Product Design

R&D

Orthopedic

V&V

Design For Manufacturing

Solidworks

Product Launch

Engineering

Project Management

Pro Engineer

Biomedical Engineering

Commercialization

Cross Functional Team Leadership

Quality System

Orthopedics

Design of Experiments

Iso

Mechanical Engineering

Validation

Biomaterials

Innovation Development

Arthroscopy

Minimally Invasive Procedures

Gd&T

Surgical Instruments

U.s. Food and Drug Administration

Implants

Iso 14971

Quality Auditing

Working With Surgeons

Interests:

Endurance Sports

Travel

Skiing

Sailing

Travel

Skiing

Sailing

Languages:

English

French

French

Flickr

Youtube

Classmates

Douglas Snell

view sourceSchools:

Mt. Hermon High School Mt. Hermon LA 1953-1957

Community:

Sherita Lewis, Sherry James, Barry Mckinney, Gloria James

Douglas Snell

view sourceSchools:

Mt. Hermon High School Mt. Hermon LA 1945-1957

Community:

Sherita Lewis, Sherry James, Barry Mckinney, Gloria James

Douglas Snell

view sourceSchools:

Red Land High School Lewisberry PA 1966-1970

Community:

Stacey Bumbernick, Robert Swenson

Douglas Snell

view sourceSchools:

Upper Dauphin High School Elizabethville PA 1997-2001

Mt. Hermon High School, M...

view sourceGraduates:

Douglas Snell (1953-1957),

Bill Courtright (1979-1983),

Michael Alford (1965-1969),

Carolyn McClendon (1967-1971),

Janice Brumfield (1981-1985)

Bill Courtright (1979-1983),

Michael Alford (1965-1969),

Carolyn McClendon (1967-1971),

Janice Brumfield (1981-1985)

Red Land High School, Lew...

view sourceGraduates:

Priscilla Pope (1996-2000),

Robin Harbold (1976-1980),

Sergio Perez (2001-2005),

Douglas Snell (1966-1970),

Loretta Witters (1995-1999)

Robin Harbold (1976-1980),

Sergio Perez (2001-2005),

Douglas Snell (1966-1970),

Loretta Witters (1995-1999)

Find people: Doug Snell |...

view source

Amherst County High Schoo...

view sourceGraduates:

Christina Douglas (1994-1998),

Marcia Goodwin (1974-1978),

Michael Campbell (1971-1975),

Heather Chenault (1990-1994),

Douglas Snell (1982-1986)

Marcia Goodwin (1974-1978),

Michael Campbell (1971-1975),

Heather Chenault (1990-1994),

Douglas Snell (1982-1986)

Thomas Douglas Snell Hou...

view sourceThomas Douglas Snell (Houston, TX)

Douglas Snell Jersey Sho...

view sourceDouglas Snell (Jersey Shore, NJ)

Doug Snell

view source

Douglas Snell

view sourceGoogleplus

Douglas Snell

Douglas Snell

Plaxo

Douglas W. Snell, Sr. CFM...

view sourceEphrata, PAPast: Area Manager SE PA at Windstream Communications, VP Facilities & Purchasing; Director;... Seasoned professional in the telecommunications industry. Present facilities management consultant. Past positions include responsibility for real estate... Seasoned professional in the telecommunications industry. Present facilities management consultant. Past positions include responsibility for real estate, facilities engineering and maintenance (environmentals that support switching centers and office buildings to include but not limited to fire...

Myspace

Get Report for Douglas B Snell from South Portland, ME, age ~57