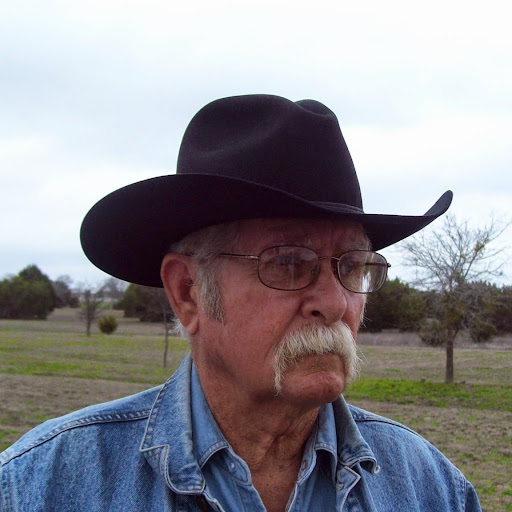

Francis Gerald Smith

age ~91

from Grosse Pointe Shores, MI

- Also known as:

-

- Francis G Smith

- Fg Smith

- Gail M Smith

- Smith F Gerald

Francis Smith Phones & Addresses

- Grosse Pointe Shores, MI

- 3101 Lake Shore Dr, Lake Leelanau, MI 49653 • 2312567809 • 2312569093

- Naples, FL

- Farmington Hills, MI

- Buffalo, NY

- Novi, MI

Lawyers & Attorneys

Francis Smith - Lawyer

view sourceOffice:

UMass Memorial Health Care, Inc.

Specialties:

Health Care

Corporate Law

Real Estate

Corporate Law

Real Estate

ISLN:

914128609

Admitted:

1995

University:

University of Massachusetts, B.A., 1988

Law School:

Suffolk University, J.D., 1994

Francis Smith - Lawyer

view sourceISLN:

901440615

Admitted:

1990

University:

Southern Methodist University, B.A.; University of Dallas, 1985

Law School:

Southern Methodist University, J.D., 1989

Francis Smith - Lawyer

view sourceSpecialties:

Health Law

Managed Care

Government Contracts

Managed Care

Government Contracts

ISLN:

903624655

Admitted:

1973

University:

Johns Hopkins University, B.A., 1970

Law School:

Georgetown University Law Center, J.D., 1973

Isbn (Books And Publications)

The Queen, on the Prosecution of Giovanni Giacinto Achilli V John Henry Newman for Criminal Libel, Court of Queen's Bench, Westminister [sic] 1851-1853

view sourceAuthor

Francis Benjamin Smith

ISBN #

0731548140

Children from Broken Homes: An Empirical Study

view sourceAuthor

Francis Benjamin Smith

ISBN #

0869652133

Wikipedia References

Francis Smith

About:

Died:

1701

Work:

In 1687 he was appointed Lord-Lieutenant of Worcestershire, a post he held until 1689..

Us Patents

-

Motor Vehicle Seat System

view source -

US Patent:6572171, Jun 3, 2003

-

Filed:Nov 17, 2000

-

Appl. No.:09/732426

-

Inventors:Rick F Pautz - Bloomfield Hills MI

Francis Nile Smith - Clarkston MI

Donna A Watson - Clinton Township MI -

Assignee:General Motors Corporation - Detroit MI

-

International Classification:B60N 202

-

US Classification:296 64, 296 6509, 296 6516, 2773441

-

Abstract:A motor vehicle seat system includes a row of front seats, a row of back seats separated from the row of front seats by a lateral isle, a longitudinal aisle through the front row, and a middle seat in the back row having a full-row position behind the lateral aisle and a half-row position overlapping the front row and the lateral aisle. In its full-row position, the middle seat cooperates with the back row seats for bench-type seating. In its half-row position, the middle seat provides a rigid platform for a child seat closer to occupants of the front row seats. The middle seat includes a removable lower frame, a seat cushion frame, a seat back frame pivotally connected to the seat cushion frame, and a mechanical linkage supporting the seat cushion frame on the lower frame for translation between an extended position corresponding to the half-row position of the middle seat and a retracted position corresponding to the full-row position of the middle seat. The seat back frame is pivotable between an upright position and flat position during which the mechanical linkage drops the seat cushion frame to a lowered position below the seat back frame.

-

Electronic Seat Occupant Classification System

view source -

US Patent:6918612, Jul 19, 2005

-

Filed:Mar 7, 2003

-

Appl. No.:10/384282

-

Inventors:Francis N. Smith - Clarkston MI, US

Joshua Forwerck - Royal Oak MI, US

Bradford Gauker - Clinton Township MI, US -

Assignee:Autoliv ASP, Inc. - Ogden UT

-

International Classification:B60R021/32

-

US Classification:280735, 180273, 200 85 A, 340667

-

Abstract:An occupant classification system for recognizing the type of occupant of a motor vehicle seat especially for use in controlling an inflatable restraint system. The classification system utilizes a number of on-off electrical switches arranged in a pattern on a seat cushion mat. Signals from the switches may be processed in a variety of manners to characterize the occupant.

-

Compound Angle Cutting Edge And Method Of Using Same

view source -

US Patent:40020924, Jan 11, 1977

-

Filed:Nov 7, 1975

-

Appl. No.:5/630067

-

Inventors:Billy R. Smith - Warren MI

Francis Moses Smith - Warren MI -

Assignee:B & M Die Co., Inc. - Warren MI

-

International Classification:B26F 144

-

US Classification:83 55

-

Abstract:A novel compound angle cutting edge configuration on a die rule, slitter blade, hollow punches, shearing blades, etc. provides cleaner cuts on stock material with less tonnage, improved cutting and cleaner cuts. The die rule cutting edge includes a plurality of side by side notches on only one side of the cutting edge defining a plurality of equally spaced piercing points. A primary cutting edge extends from each piercing point substantially to a next adjacent piercing point and forms a compound angle with an imaginary line through the tips of the piercing points of between about one and fifteen degrees. In use, the cutting edges are axially pressed through stock material to cut blanks of predetermined configuration. The cutting action consists of the piercing points penetrating the material and then the primary cutting edges slicing the stock material from one penetration point, substantially linearly and unidirectionally, to the next adjacent penetration point.

-

Compound Angle Cutting Edge

view source -

US Patent:39618587, Jun 8, 1976

-

Filed:Jun 11, 1975

-

Appl. No.:5/585802

-

Inventors:Billy R. Smith - Warren MI

Francis Moses Smith - Warren MI -

Assignee:B&M Die Co., Inc. - Warren MI

-

International Classification:B23B 5104

-

US Classification:408204

-

Abstract:A novel compound angle cutting edge configuration on a die rule, slitter blade, hollow punches, shearing blades, etc. provides cleaner cuts on stock material with less tonnage, improved cutting and cleaner cuts. The die rule cutting edge includes a plurality of side by side notches on only one side of the cutting edge defining a plurality of equally spaced piercing points. A primary cutting edge extends from each piercing point substantially to a next adjacent piercing point and forms a compound angle with an imaginary line through the tips of the piercing points of between about one and fifteen degrees. In use, the cutting edges are axially pressed through stock material to cut blanks of predetermined configuration. The cutting action consists of the piercing points penetrating the material and then the primary cutting edges slicing the stock material from one penetration point, substantially linearly and unidirectionally, to the next adjacent penetration point.

-

Apparatus For Manufacturing Linerless Labels

view source -

US Patent:6153045, Nov 28, 2000

-

Filed:May 24, 1995

-

Appl. No.:8/449327

-

Inventors:John R. Soltysiak - Blasdell NY

John C. Bane - Grand Island NY

Frank L. Benchik - Pendleton NY

Paul M. Cumming - Grand Island NY

Jimme A. Harrod - Grand Island NY

Dennis D. Hubbell - Grand Island NY

Khaled M. Khatib - Youngstown NY

Joseph W. Langan - Cheektowaga NY

Nancy G. Mitchell - Grand Island NY

Daniel P. Ratka - Amherst NY

Timothy J. Russ - Lewiston NY

Francis R. Smith - North Tonawanda NY -

Assignee:Moore Business Forms, Inc. - Grand Island NY

-

International Classification:B32B 3112

B05D 510

B05C 504 -

US Classification:1563796

-

Abstract:An apparatus and method provide for the alternate manufacture of permanent adhesive or repositional linerless labels utilizing the same equipment. Indicia is applied such as by using an intelligent imaging system by at least one print station. With repositional labels, a tie coat is applied and dried, whereas with permanent labels a barrier coating is applied. Coating stations apply a repositional adhesive and release coat in the construction of repositional adhesive labels. The coating station is followed by a dryer and chill rolls. In the construction of permanent adhesive labels a coating station for applying a release coat and a release coat curing station, as well as permanent adhesive application station, are also provided. Changeover time from the manufacture of one type of label to the other is short.

-

Double Faced Tape With Repositional Adhesive

view source -

US Patent:61688290, Jan 2, 2001

-

Filed:Jan 21, 1993

-

Appl. No.:8/006517

-

Inventors:Timothy J. Russ - North Tonawanda NY

Francis R. Smith - Niagara Falls NY -

Assignee:Moore Business Forms, Inc. - Grand Island NY

-

International Classification:C09J 702

-

US Classification:4272084

-

Abstract:A double sided tape has repositional with adhesive associated with a first face. The tape may be in the form of a roll, and the adhesive on the second face may be either repositional or permanent. In order to facilitate rolling, a release liner is provided on one of the adhesive faces. The tape may have perforations, notches, or slits along its length to facilitate detachment of predefined lengths of the tape, as from a dispenser. A tie coat may be applied to each of the faces of the substrate before the adhesive is applied. One face of adhesive can be readily applied to one object (e. g. , a shelf or a piece of paper), while the repositional adhesive is then available to removably attach that object to another object (e. g. , another piece of paper).

-

Method And Apparatus For Manufacturing Linerless Labels

view source -

US Patent:55187625, May 21, 1996

-

Filed:Jun 3, 1994

-

Appl. No.:8/253787

-

Inventors:John R. Soltysiak - Blasdell NY

John C. Bane - Grand Island NY

Frank L. Benchik - Pendleton NY

Paul M. Cumming - Grand Island NY

Jimme A. Harrod - Grand Island NY

Dennis D. Hubbell - Grand Island NY

Khaled M. Khatib - Youngstown NY

Joseph W. Langan - Cheektowaga NY

Nancy G. Mitchell - Grand Island NY

Daniel P. Ratka - Amherst NY

Timothy J. Russ - Lewiston NY

Francis R. Smith - North Tonawanda NY -

Assignee:Moore Business Forms, Inc. - Grand Island NY

-

International Classification:B05D 510

-

US Classification:427208

-

Abstract:An apparatus and method provide for the alternate manufacture of permanent adhesive or repositional linerless labels utilizing the same equipment. Indicia is applied such as by using an intelligent imaging system by at least one print station. With repositional labels, a tie coat is applied and dried, whereas with permanent labels a barrier coating is applied. Coating stations apply a repositional adhesive and release coat in the construction of repositional adhesive labels. The coating station is followed by a dryer and chill rolls. In the construction of permanent adhesive labels a coating station for applying a release coat and a release coat curing station, as well as permanent adhesive application station, are also provided. Changeover time from the manufacture of one type of label to the other is short.

-

Tumble Forward Seat With Automatic Seat Adjuster Return

view source -

US Patent:59611839, Oct 5, 1999

-

Filed:Mar 25, 1998

-

Appl. No.:9/047791

-

Inventors:Francis Nile Smith - Clarkston MI

Carmen Leigh Markstrom - Novi MI -

Assignee:General Motors Corporation - Detroit MI

-

International Classification:A47C 102

-

US Classification:297322

-

Abstract:A tumble forward seat for a van or the like includes a device to automatically unlatch the seat adjuster, return the seat from any forwardly adjusted position to its rearwardmost position, and relatch the seat adjuster, during the forward rotation. A specially designed cam and lift lever push the pivoting release handle of the seat adjuster up and open and hold it open while a wedging surface and pusher block react against one another to shift the seat cushion frame back. The lift lever resets itself as the seat is rotated back. The cam, lift lever, and wedging surface are coordinated to one another so as to always provide the correct degree of opening and shifting motion, regardless of initial seat adjusted position.

License Records

Francis E. Smith

License #:

E-3677 - Expired

Category:

Engineering Intern

Francis Smith

License #:

70105082 - Active

Category:

EMS Licensing

Issued Date:

Apr 16, 2016

Expiration Date:

Jun 30, 2018

Type:

First Responder (EMR)

Francis W Smith

License #:

5911 - Expired

Expiration Date:

Jun 30, 1984

Type:

Mechanical Engineer

Francis V Smith

License #:

58866 - Expired

Issued Date:

Mar 1, 1968

Expiration Date:

Sep 18, 1981

Type:

Broker

Francis E Smith

License #:

107534 - Expired

Issued Date:

Feb 1, 1979

Expiration Date:

May 31, 1999

Type:

Broker

Francis D Smith Md

License #:

9736 - Expired

Category:

Medicine

Issued Date:

Mar 29, 1955

Effective Date:

Aug 17, 1987

Type:

Physician

Francis J Smith

License #:

RS154777A - Expired

Category:

Real Estate Commission

Type:

Real Estate Salesperson-Standard

Francis T Smith

License #:

RS115024A - Expired

Category:

Real Estate Commission

Type:

Real Estate Salesperson-Standard

Name / Title

Company / Classification

Phones & Addresses

President

Bio-Concept Laboratories, Inc.

Product Development & Marketing

Product Development & Marketing

4 Tinkham Avenue, #104, Derry, NH 03038

6034374990, 6034374998

6034374990, 6034374998

Vice President

Treasure Coast Marine of Vero, Inc.

Marine Contractors

Marine Contractors

1206 1st Ave., SE, Vero Beach, FL 32962

7727785702

7727785702

Principal

Frs Appraisals

Real Estate Agent/Manager

Real Estate Agent/Manager

2742 Costa Mesa Rd, Waterford, MI 48329

CENTRAL STATES DISTRIBUTION, LTD

AT XPRESS, LLC

MSCS LTD

Francis Smith MD

Internist

Internist

2171 Pne Rdg Rd, Naples, FL 34109

2392637425

2392637425

FWS MANAGEMENT SYSTEMS, LTD

Medicine Doctors

Dr. Francis E Smith, Naples FL - MD (Doctor of Medicine)

view sourceSpecialties:

Internal Medicine

Address:

811 7Th Ave S, Naples, FL 34102

2392637425 (Phone), 2392633430 (Fax)

2392637425 (Phone), 2392633430 (Fax)

Certifications:

Internal Medicine, 1977

Awards:

Healthgrades Honor Roll

Languages:

English

Education:

Medical School

Tufts University

Medical School

St Elizabeths Hosp

Tufts University

Medical School

St Elizabeths Hosp

Francis J. Smith

view sourceSpecialties:

Podiatric Medicine, Orthopaedic Surgery

Work:

Laurel Foot & Ankle Center

14440 Cherry Ln Ct STE 104, Laurel, MD 20707

3019533668 (phone), 3019533854 (fax)

Northern Virginia Foot & Ankle Associates

8221 Old Courthouse Rd STE 102, Vienna, VA 22182

7037341311 (phone), 7037349090 (fax)

14440 Cherry Ln Ct STE 104, Laurel, MD 20707

3019533668 (phone), 3019533854 (fax)

Northern Virginia Foot & Ankle Associates

8221 Old Courthouse Rd STE 102, Vienna, VA 22182

7037341311 (phone), 7037349090 (fax)

Conditions:

Hallux Valgus

Plantar Fascitis

Tinea Pedis

Plantar Fascitis

Tinea Pedis

Languages:

English

Spanish

Spanish

Description:

Dr. Smith works in Vienna, VA and 1 other location and specializes in Podiatric Medicine and Orthopaedic Surgery. Dr. Smith is affiliated with Laurel Regional Hospital and Virginia Hospital Center.

Plaxo

Francis Smith

view source

Francis Smith

view sourcePresident & CEO at Bio Concept Laboratories Past: Manager, Pharmaceutical Development at Telor Ophthalmic Pharmaceuticals, Manager... Received Ph.D. in Biochemistry from the University of Massachusetts, Lowell. Hold a M.S. in Chemistry from the Rochester Institute of Technology and a B.S. in... Received Ph.D. in Biochemistry from the University of Massachusetts, Lowell. Hold a M.S. in Chemistry from the Rochester Institute of Technology and a B.S. in Medicinal Chemistry from SUNY at Buffalo. Have over 40 U.S. Patents and is an author on 13 scientific publications and abstracts. Over 35...

Francis Smith

view sourceOver 15 years of recruitment and staffing experience, with expertise in developing and delivering high-volume staffing programs to wide variety of... Over 15 years of recruitment and staffing experience, with expertise in developing and delivering high-volume staffing programs to wide variety of organizations. Also possess strong experience in executing recruitment initiatives to fill various professional and managerial positions in the...

Classmates

Francis Runions (Smith)

view sourceSchools:

Perry County High School Marion AL 1992-1996

Community:

Lucy Davis, Sammie Robertson, Wendy Franklin, Lynn Warren, Jenny Sorrell, Davis Morrison

Biography:

Hey guys.. I just finished aesthetician school, and opening up my own business in Ho...

Francis Smith

view sourceSchools:

Greentown High School Greentown IN 1927-1931

Community:

Shirl Neal

Francis Ruffin (Smith)

view sourceSchools:

Harris High School Meridian MS 1964-1966

Community:

John Cole, Jacqueline Brown, Janice Bowden, Preston Jones

Francis Smith

view sourceSchools:

Montvale High School Montvale VA 1954-1958

Community:

Joyce Ramsey, Edna Vaughan

Francis Smith

view sourceSchools:

Salamonie Township High School Warren IN 1946-1950

Community:

Sonja Williams, Marilyn Michael

Francis Smith

view sourceSchools:

Garden Hills Elementary School Atlanta GA 1951-1958

Community:

Jolie Ellis, John Winecoff, Kathleen Peters, Carol Byrne

Francis Smith

view sourceSchools:

Fairmount High School Baltimore MD 1972-1976

Community:

Clarence Cole, Kate O'connor

Francis Smith

view sourceSchools:

Corpus Christi Parochial School Philadelphia PA 1955-1959

Community:

Joseph Wright, Thomas Collier, Martin Heenan, Joan Lentz, Maryanne Zimmerman

Francis Domingo Smith

view source

Francis Halley Smith

view source

Francis Xaiver Smith

view source

Jeffrey Francis Smith

view source

Francis Martin Smith

view source

Francis William Smith

view source

Francis Barbara Smith

view source

Francis Asbury Smith

view sourceGoogleplus

Francis Smith

Work:

Phillups Petroleum - Corporate quality assurance manager

Education:

Pascagoula high school, Pascagoula , Ms. - Girls, Mississippi gulf coast junior college at Gautier, Ms - Humanities

Relationship:

Married

Bragging Rights:

I have spent much of my time traveling the west. I retired from a major oil company who gets credit for bringing me to Texas.

Francis Smith

Work:

Retired

Education:

Moorefield high school

Francis Smith

Work:

Lonza Group - Senior Manufacturing Associate (11)

Francis Smith

Work:

Santa Clara University - Ass't Prof

Francis Smith

Tagline:

Pinnacle of Perfection

Francis Smith

Francis Smith

Francis Smith

Youtube

Myspace

Flickr

Get Report for Francis Gerald Smith from Grosse Pointe Shores, MI, age ~91