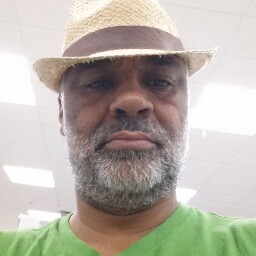

Gerald V Adams

age ~61

from Detroit, MI

- Also known as:

-

- Jerald Adams

Gerald Adams Phones & Addresses

- Detroit, MI

- Chicago, IL

- Houston, TX

- San Antonio, TX

- Fort Worth, TX

Resumes

Gerald Adams West Hempstead, NY

view sourceWork:

Faith Evangelical Church

Sep 1990 to 2000

Senior Pastor Middle and High Schools

Sep 2002 to Aug 2004

Chancellor/Principal Christian Fellowship of Nashport

Nashport, OH

Jun 1978 to Aug 1990

Senior Pastor New Life Christian College

Zanesville, OH

1986 to 1989

Instructor of Apologetics & Bible Survey Christian Life Church

Mount Prospect, IL

May 1977 to Jun 1978

Praise and worship leader Neighborhood Church

Fort Payne, AL

Sep 1976 to May 1977

Piano and organ accompanist Rock Church

Rockford, IL

Sep 1973 to Sep 1976

Sunday school teacher Philadelphia Church

Chicago, IL

Sep 1968 to Sep 1973

Member/Attendee

Sep 1990 to 2000

Senior Pastor Middle and High Schools

Sep 2002 to Aug 2004

Chancellor/Principal Christian Fellowship of Nashport

Nashport, OH

Jun 1978 to Aug 1990

Senior Pastor New Life Christian College

Zanesville, OH

1986 to 1989

Instructor of Apologetics & Bible Survey Christian Life Church

Mount Prospect, IL

May 1977 to Jun 1978

Praise and worship leader Neighborhood Church

Fort Payne, AL

Sep 1976 to May 1977

Piano and organ accompanist Rock Church

Rockford, IL

Sep 1973 to Sep 1976

Sunday school teacher Philadelphia Church

Chicago, IL

Sep 1968 to Sep 1973

Member/Attendee

Education:

Christian Life College

Mount Prospect, IL

May 2000

Bachelor of Arts in Ministerial Studies Triton College

River Grove, IL

Sep 1977 to May 1978

Accounting, Computer Math, and Personal Chicago Bible College

Mount Prospect, IL

May 1972

Diploma in Theology East Leyden High School

Franklin Park, IL

Jun 1968

Diploma Ohio University

Zanesville, OH

Philosophy and Piano

Mount Prospect, IL

May 2000

Bachelor of Arts in Ministerial Studies Triton College

River Grove, IL

Sep 1977 to May 1978

Accounting, Computer Math, and Personal Chicago Bible College

Mount Prospect, IL

May 1972

Diploma in Theology East Leyden High School

Franklin Park, IL

Jun 1968

Diploma Ohio University

Zanesville, OH

Philosophy and Piano

Gerald Adams Abbeville, LA

view sourceWork:

global geophysical services

Missouri City, TX

Jun 2012 to Jun 2013

seismic linesman/ head linesman Q based healthcare

Erath, LA

Aug 2008 to May 2012

online shipping specialist/ warehouse person

Missouri City, TX

Jun 2012 to Jun 2013

seismic linesman/ head linesman Q based healthcare

Erath, LA

Aug 2008 to May 2012

online shipping specialist/ warehouse person

Education:

abbeville high school

Abbeville, LA

1995 to 1999

Ged diploma in General

Abbeville, LA

1995 to 1999

Ged diploma in General

Skills:

organization skills, professional attitude, likes fast paced work environment.

Gerald Adams Houston, TX

view sourceWork:

Naval Security Force

Oct 2011 to 2000

Naval Security Force Officer US Navy

Kings Bay, GA

Jan 2006 to Jan 2007

Missile Technician Apprentice

Oct 2011 to 2000

Naval Security Force Officer US Navy

Kings Bay, GA

Jan 2006 to Jan 2007

Missile Technician Apprentice

Education:

Forest Brook High School

Houston, TX

Dec 2006

Certificate of Completion in Electronics Tester

Houston, TX

Dec 2006

Certificate of Completion in Electronics Tester

Skills:

Microsoft Office Suite (Outlook, Word, Excel, PowerPoint), SharePoint, AutoCad, Autodesk Maya3D, CNIC Navy Security Force Training Course, October 2011

Lawyers & Attorneys

License Records

Gerald Adams

Address:

8419 Lanewood Dr, Houston, TX 77016

Phone:

8327075107

License #:

228474 - Active

Category:

Barber, Class A

Expiration Date:

Dec 8, 2018

Gerald W Adams

License #:

7913 - Expired

Category:

Emergency Medical Care

Issued Date:

Dec 31, 1996

Effective Date:

Jul 19, 2005

Expiration Date:

Dec 31, 1999

Type:

EMT

Isbn (Books And Publications)

Advanced Topics on Radiosensitizers of Hypoxic Cells

view sourceAuthor

Gerald E. Adams

ISBN #

0306409151

Name / Title

Company / Classification

Phones & Addresses

President

Orion Security & Document Services(1990) Ltd.

Personal Security Guard Service. Process Servicers

Personal Security Guard Service. Process Servicers

Box 664, Portage la Prairie, MB R1N 3C2

2042397108, 2042390947

2042397108, 2042390947

Scootaround Inc (Headquarters)

Wheelchairs - renting

Wheelchairs - renting

Unit C - 1150 Waverley Street, Winnipeg, MB R3T 0P4

8884417575, 2044781172

8884417575, 2044781172

President

Adams Partners

Employment Agencies

Employment Agencies

205 W Wacker Dr Ste 810, Chicago, IL 60606

Owner

G J Adams' Guns

Ret Sporting Goods/Bicycles

Ret Sporting Goods/Bicycles

8318 Windfall Ln, Houston, TX 77040

7134664871

7134664871

President

Adams Partners

Employment Agencies

Employment Agencies

205 W Wacker Dr STE 810, Chicago, IL 60606

3125775648

3125775648

President

Orion Security & Document Services(1990) Ltd

Personal Security Guard Service · Process Servicers

Personal Security Guard Service · Process Servicers

2042397108, 2042390947

Director

J-B-A Designs, Inc

Vice President

DE LEUW, CATHER & COMPANY

Transportation Engineering And Planning

Transportation Engineering And Planning

Washington, DC 20003

100 M St, Washington, DC 20003

16055 SPACE CENTER BLVD STE 725, Houston, TX 77062

16055 Space Ctr Blvd STE 725, Houston, TX 77062

3129305100, 3129300018, 2027753300, 2027753422

100 M St, Washington, DC 20003

16055 SPACE CENTER BLVD STE 725, Houston, TX 77062

16055 Space Ctr Blvd STE 725, Houston, TX 77062

3129305100, 3129300018, 2027753300, 2027753422

Us Patents

-

Precipitation Of Scale Inhibitors In Subterranean Formations

view source -

US Patent:53460103, Sep 13, 1994

-

Filed:Mar 31, 1993

-

Appl. No.:8/040784

-

Inventors:Gerald C. Adams - Sugar Land TX

Robert J. Faircloth - Houston TX

Jimmie B. Lawson - Houston TX -

Assignee:Shell Oil Company - Houston TX

-

International Classification:E21B 4312

E21B 4322 -

US Classification:166279

-

Abstract:Scale inhibitors are precipitated in a formation by injection in an acidic solution comprising a base generating component and a chelating agent. The inhibitor is preferably a calcium salt of an organic phosphonate. The chelating agent prevents iron ions from causing premature hydrolysis of the base generating component.

-

Acid Stimulation Process For Production From Subterranean Formations

view source -

US Patent:53928598, Feb 28, 1995

-

Filed:Dec 2, 1993

-

Appl. No.:8/160995

-

Inventors:Gerald C. Adams - Sugar Land TX

Jimmie B. Lawson - Houston TX

Lee N. Morgenthaler - Houston TX -

Assignee:Shell Oil Company - Houston TX

-

International Classification:E21B 4327

-

US Classification:166300

-

Abstract:The present invention is a method to improve permeability of a formation in the vicinity of a production wellbore. An acid treatment composition is placed in the formation after a foaming composition is injected and a foam created from the foaming composition, thus forcing the acid treatment composition into less permeable strata. The foaming composition contains a sulfate surfactant as a foam stabilization agent. The sulfate hydrolyzes after a time period that is long enough to permit placement of the acid treatment composition. After the sulfate hydrolyzes, it becomes ineffective as a surfactant. Fluids produced from the formation after the acid treatment according to the present invention therefore do not contain significant concentrations of active surfactants, and therefore do not create foams or emulsions in surface separation equipment.

-

Formation Fracturing

view source -

US Patent:54602262, Oct 24, 1995

-

Filed:May 18, 1994

-

Appl. No.:8/245730

-

Inventors:Jimmie B. Lawson - Houston TX

Gerald C. Adams - Sugar Land TX

Robert J. Faircloth - Houston TX -

Assignee:Shell Oil Company - Houston TX

-

International Classification:E21B 4326

-

US Classification:166300

-

Abstract:A method is provided to fracture a subterranean formation along with a fracturing fluid useful in this method, the method comprising the steps of: a) providing a fracturing fluid, the fracturing fluid is an aqueous solution having an initial pH greater than about 8 and comprising a polysaccharide, a source of borate in an amount that is effective to crosslink the polysaccharide at a pH greater than 8, an oxidative breaker, and a precursor that hydrolyzes in an amount that is effective to lower the pH of the fracturing fluid after a time period that is greater than about one half hour and less than about two days; b) injecting the fracturing fluid into the formation at a pressure the is effective to fracture the formation and force at least a portion of the fracturing fluid into the fracture; and c) permitting the precursor to hydrolyze and thereby lowering the pH of the fracturing fluid to a pH that is less than about 8.

Classmates

Gerald Adams

view sourceSchools:

John I. Meister Elementary School Hobart IN 1970-1976

Community:

Myra Utley, Darlene Coomes

Gerald Adams

view sourceSchools:

De Tour Village High School De Tour Village MI 1965-1969

Community:

Ted Bailey, Nikki Parridgen, Denise De Bussey, Liar Reborn, Patricia Questard

Gerald Adams (Colonel)

view sourceSchools:

Feldwood High School College Park GA 1978-1982

Community:

Melissa Priest, Tynesia Alston

Gerald Adams

view sourceSchools:

Venetian Hills Elementary School Atlanta GA 1989-1994, Young Middle School Atlanta GA 1994-1998

Gerald Adams

view sourceSchools:

Calvary Christian Academy Montgomery AL 1985-1989

Community:

Mary Cocking

Gerald Adams

view sourceSchools:

Orange High School Orange TX 1979-1983

Community:

Wanda Hadley, Maude Blankinship, David Seal, Sandy Sides, Jeffrey Tice

Gerald Adams

view sourceSchools:

Mt. Carmel High School Vancleve KY 1961-1965

Community:

Donna Lunger, Ramona Young, Anne Ballou, Martha Albee

Gerald Adams

view sourceSchools:

Hawkins High School Hawkins WI 1958-1962

Community:

Mary Brzezinski

Youtube

Plaxo

Kenneth Gerald Adams

view source

Gerald Adams

view sourceShreveportVice President at AAA Insulators Sales Co

Gerald Adams

view sourceRetired

Googleplus

Gerald Adams

Gerald Adams

Gerald Adams

Gerald Adams

Gerald Adams

Gerald Adams

Gerald Adams

Gerald Adams

Gerald Adams

view source

Gerald Adams

view source

Gerald Bit Adams

view source

Gerald Richard Adams

view source

Gerald Dwain Adams

view source

Gerald Adams

view source

Gerald Adams

view source

Gerald Lubin Adams

view sourceFlickr

Get Report for Gerald V Adams from Detroit, MI, age ~61