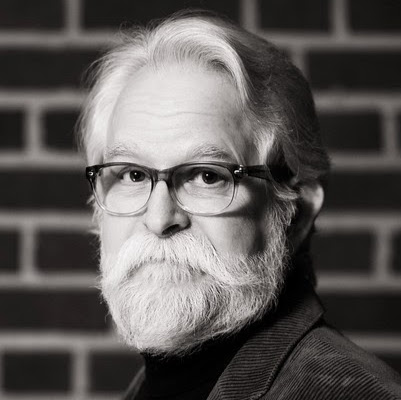

Gerald Thomas Cox

age ~58

from Versailles, KY

- Also known as:

-

- Gerald T Cox

- Gerald D Cox

- Gerald J Cox

- Bo Cox

- Phone and address:

- 560 Will Pkwy, Versailles, KY 40383

Gerald Cox Phones & Addresses

- 560 Will Pkwy, Versailles, KY 40383

- Lexington, KY

- Winter Park, FL

- Fort Myers, FL

- Crystal River, FL

Name / Title

Company / Classification

Phones & Addresses

Director

SCREAMIN' MIMI'S SALSA, INC

Mfg Canned Specialties

Mfg Canned Specialties

1004 Red Rain Cir, Lexington, KY 40515

8592738543

8592738543

President, Treasurer, Secretary, Director

Cox Plumbing of Orlando I

Plumbing, Heating, Air-Conditioning, Nsk · Plumbing/Heating/Air Cond Contractor · Plumbing/Heating/Air Cond Contractor Repair Services Ret Misc Merchandise

Plumbing, Heating, Air-Conditioning, Nsk · Plumbing/Heating/Air Cond Contractor · Plumbing/Heating/Air Cond Contractor Repair Services Ret Misc Merchandise

141 N Orange Ave, Sanford, FL 32771

177 W Maine Ave, Longwood, FL 32750

PO Box 520399, Longwood, FL 32752

4073320660, 4078786099, 4078786058

177 W Maine Ave, Longwood, FL 32750

PO Box 520399, Longwood, FL 32752

4073320660, 4078786099, 4078786058

HERTRAM PUBLISHING AND PRODUCTION LLC

DOXOLOGY MINISTRIES INTERNATIONAL INC

COX PROPERTY GROUP, INC

COX CUSTOM AUTO, INC

MT. OLIVE FURNACE PARK CORPORATION

Director

Internal Auditing Academic Advancement Fund, Inc

Medical Doctor's Office

Medical Doctor's Office

247 Maitland Ave, Altamonte Springs, FL 32701

Us Patents

-

Incremental Rotary Encoder

view source -

US Patent:43755925, Mar 1, 1983

-

Filed:Dec 19, 1980

-

Appl. No.:6/218153

-

Inventors:Gerald L. Cox - Nicholasville KY

Randall A. Maddox - Georgetown KY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:G01D 534

-

US Classification:250231SE

-

Abstract:A field replaceable encoder including a slotted housing having a pair of passages therethrough essentially perpendicular to the longitudinal axis of the housing, is attachable to the frame of a machine having a rotatable shaft to which the encoder is to be mounted. Attached to the housing is an accurate stationary mask, the mask having slits which are aligned with the passages in the housing. The mask includes an accurately dimensioned aperture for locating the mask, and thus the housing, on a bearing on the rotatably mounted shaft. A pair of light sources and a pair of light detectors are mounted on opposite sides of the housing aligned with the passages and slits in the mask. A hub, to which is attached a rotating disc, is connected to the rotating shaft, the disc being mounted in the slotted housing so that interdigitated opaque and transparent portions align with the slits of the mask, and thus the light sources and light detectors. In the preferred embodiment, the light sources are mounted in the passages (tunnel like in formation) which converge at their outlets and which prevents having to employ collimated light sources while inhibiting cross-talk between the detectors and adjacent sources allowing for close spacing of the source pair and the detector pair.

-

Burner Nozzle With Backflow Prevention For A Fluidized Bed Biogasifier

view source -

US Patent:20180094199, Apr 5, 2018

-

Filed:Oct 5, 2017

-

Appl. No.:15/725637

-

Inventors:- Nashville TN, US

Ross M. Patten - Paul Coast FL, US

Paul CAIRNEY - Deltona FL, US

Gerald M. Cox - Cocoa FL, US

William P. Jepson - Orlando FL, US

Benjamin F. Gardner - Simpsonville SC, US -

International Classification:C10J 3/46

C10J 3/84 -

Abstract:A fluidized bed biogasifier is provided for gasifying biosolids. A feeder feeds biosolids into a reactor vessel at a desired feed rate during steady-state operation. A fluidized bed in the base of the reactor vessel has a cross-sectional area that is proportional to at least the fuel feed rate such that the superficial velocity of gas is in the range of 0.1 m/s to 3 m/s. The biosolids are heated inside the fluidized bed reactor to a temperature range between 900 F. and 1700 F. in an oxygen-starved environment having a sub stoichiometric oxygen level, whereby the biosolids are gasified. A burner system having a hooded nozzle below the fluidized bed in the reactor vessel provides high temperature gas to the biogasifier.

Isbn (Books And Publications)

License Records

Gerald P Cox

License #:

46 - Active

Category:

Nursing Home Administrator

Expiration Date:

Sep 30, 2017

Gerald W Cox

License #:

2705057833 - Expired

Category:

Contractor

Issued Date:

Aug 10, 2000

Expiration Date:

Aug 31, 2004

Type:

Class C

Gerald W Cox

License #:

2705042235 - Expired

Category:

Contractor

Issued Date:

Nov 10, 1997

Expiration Date:

Nov 30, 1999

Type:

Class C

Googleplus

Gerald Cox

Work:

Axcelis Technologies - Director of Engineering (2004-2005)

Matrix Integrated Systems - COO, VP Engineering (1997-2004)

Plasma & Materials Systems - VP Engineering (1996-1997)

Texas Instruments - Branch Manager (1972-1992)

Rockwell Collins - Electronics Design Engineer (1966-1972)

Matrix Integrated Systems - COO, VP Engineering (1997-2004)

Plasma & Materials Systems - VP Engineering (1996-1997)

Texas Instruments - Branch Manager (1972-1992)

Rockwell Collins - Electronics Design Engineer (1966-1972)

Education:

Texas A&M University - BS Electrical Engineering

Tagline:

Former COO, Inventor, Engineer. Now retired looking for my future wife.

Gerald Cox

Education:

Aztec higDABCC, DABCC

Gerald Cox

Gerald Cox

Gerald Cox

Gerald Cox

Gerald Cox

Gerald Cox

Plaxo

Gerald G. Cox

view sourceSearcy, AR

Youtube

Classmates

Gerald Cox

view sourceSchools:

Linda Tutt Learning Center Sanger TX 1980-1984, Sanger High School Sanger TX 1980-1984

Community:

David Lynn, Maranda Harris, Ashley Hill, Ashlin Lannerd, Stephanie Duncan

Gerald Cox

view sourceSchools:

Friendsville High School Friendsville TN 1970-1974

Community:

Randy Lindsey, Freda Dillard, Danny Bolinger, Iva Kerr

Gerald Cox

view sourceSchools:

Villa Rica High School Villa Rica GA 1970-1974

Community:

David Byrum

Gerald Cox

view sourceSchools:

Sudan High School Sudan TX 1968-1972

Community:

Melissa Dolen, Damon Daily

Gerald Cox

view sourceSchools:

Goodrich High School Fond Du Lac WI 1964-1968

Community:

Amy Puetz, Chris Anderson

Gerald Cox

view sourceSchools:

Rancho Alamitos High School Garden Grove CA 1976-1980

Community:

Janet Tonner, Janelle Deshazer

Gerald Cox

view sourceSchools:

Independence High School Provo UT 1994-1998

Community:

Melissa Dennis, Dan Martinez, Tony Newbreast

Gerald Cox

view sourceSchools:

North Toole County High School Sunburst MT 1978-1982

Community:

Michael Hermance, David Cook

Gerald Cox

view source

Gerald Cox

view source

Gerald Cox

view source

Gerald Cox

view source

Gerald Cox

view source

Cox Gerald

view source

Thomas Gerald Cox

view source

Gerald Cox

view sourceFlickr

Myspace

Get Report for Gerald Thomas Cox from Versailles, KY, age ~58