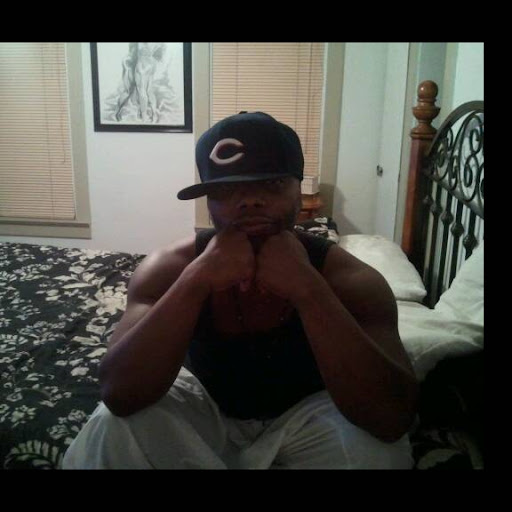

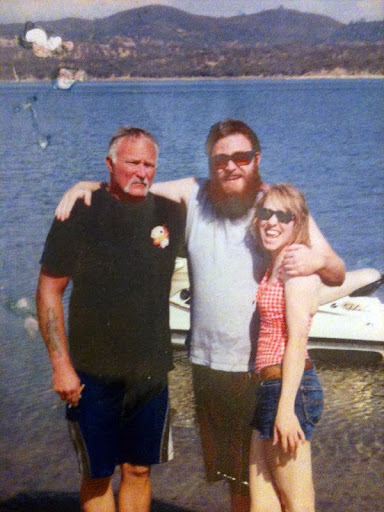

Gregory A Quinn

age ~64

from Anaheim, CA

- Also known as:

-

- Greg A Quinn

- Debbie A Quinn

- Debbie G Quinn

- Gregory A Qinn

- Phone and address:

-

316 W Berry Ave, Anaheim, CA 92805

9492855568

Gregory Quinn Phones & Addresses

- 316 W Berry Ave, Anaheim, CA 92805 • 9492855568

- Solana Beach, CA

- Orange, CA

- Laguna Niguel, CA

- Downey, CA

- 316 W Berry Ave, Anaheim, CA 92805

Work

-

Position:Sales Occupations

Education

-

Degree:High school graduate or higher

Us Patents

-

Active Sampler For Detecting Contaminants In Liquids

view source -

US Patent:7399447, Jul 15, 2008

-

Filed:Apr 1, 2004

-

Appl. No.:10/815983

-

Inventors:William D. Bowers - Newport Beach CA, US

Gregory F. Quinn - Fullerton CA, US -

Assignee:Enigma Science, LLC - Irvine CA

-

International Classification:G01N 1/14

-

US Classification:422100, 73 6456, 7386301

-

Abstract:An active sampler for detecting contaminants in liquids comprises an inlet tube, and outlet tube and a sampling unit positioned between said paths such that the liquid flows along a path from the inlet, through the sampling unit, to the outlet. The sampling unit has a plurality of sampling chambers that are substantially fluidly sealed relative to one another, wherein one of the sampling chambers is selectively positioned in the flow path. The active sampler also comprises an actuator, which relatively moves the sampling unit and the inlet and outlet tubes such that said one sampling chamber is positioned out of the flow path while another of the sampling chambers is positioned in the flow path.

-

Active Sampler For Detecting Contaminants In Liquids

view source -

US Patent:8119065, Feb 21, 2012

-

Filed:Jul 15, 2008

-

Appl. No.:12/173612

-

Inventors:William D. Bowers - Newport Beach CA, US

Gregory F. Quinn - Fullerton CA, US -

Assignee:Enigma Science, LLC - Irvine CA

-

International Classification:G01N 1/14

-

US Classification:422 681, 73 6456, 7386301

-

Abstract:An active sampler for detecting contaminants in liquids comprises an inlet, an outlet and a sampling unit positioned such that the liquid flows along a path from the inlet, through the sampling unit, to the outlet. The sampling unit has a plurality of sampling chambers that are substantially fluidly sealed relative to one another, wherein one of the sampling chambers is selectively positioned in the flow path. The active sampler also comprises an actuator, which relatively moves the sampling unit and the inlet and outlet such that one sampling chamber is positioned out of the flow path while another of the sampling chambers is positioned in the flow path.

-

Flow Control Device

view source -

US Patent:8128058, Mar 6, 2012

-

Filed:Apr 22, 2008

-

Appl. No.:12/107724

-

Inventors:Gregory F. Quinn - Fullerton CA, US

Robert G. Morris - Yorba Linda CA, US -

Assignee:National Diversified Sales, Inc. - Woodland Hills CA

-

International Classification:F16K 31/44

-

US Classification:251 83, 251 95, 251 99, 251288, 251301

-

Abstract:A flow control device in which a flapper is continuously biased to the closed position by a leaf spring that may have a plurality of fingers. The same valve includes a shutoff mechanism allowing the user to adjust forward flow through the valve or shut it off entirely. The leaf spring is made to include polyoxymethylene.

-

Expansion Repair Coupling

view source -

US Patent:8313607, Nov 20, 2012

-

Filed:Nov 5, 2010

-

Appl. No.:12/940741

-

Inventors:Gregory F. Quinn - Fullerton CA, US

-

Assignee:National Diversied Sales, Inc. - Lindsay CA

-

International Classification:F16L 47/00

B29C 65/48 -

US Classification:156293, 156 94, 156294, 156423, 156295, 285 30, 285 31, 285113, 285238, 285371, 285398, 285302

-

Abstract:An expansion repair coupling for interconnecting two facing ends of a cut pipe comprises a tubular body, a spigot slidably and rotatably received therein and a locking mechanism to selectively lock or unlock the rotation of the tubular body relative to the spigot. An end of the spigot extends outward from the tubular body to receive a coupling that connects to one end of the cut pipe. A radially enlarged section on the spigot has a sealing mechanism that sealably engages an interior surface of the tubular body. The locking mechanism, engaged by collapsing the spigot into the tubular body or disengaged by extending the spigot therefrom, facilitates a push and twist connection at both ends of the pipe to wipe the adhesive disposed therebetween and obtain a better seal. Preferably, the locking mechanism comprises a socket having spigot engaging members that cooperatively engage socket engaging members on the spigot.

-

Expansion Repair Coupling

view source -

US Patent:20080252068, Oct 16, 2008

-

Filed:Apr 16, 2007

-

Appl. No.:11/787663

-

Inventors:Gregory F. Quinn - Fullerton CA, US

-

International Classification:F16L 55/178

-

US Classification:285 18

-

Abstract:An expansion repair coupling for interconnecting two facing ends of a cut pipe comprises a tubular body, a spigot slidably and rotatably received therein and a locking mechanism to selectively lock or unlock the rotation of the tubular body relative to the spigot. An end of the spigot extends outward from the tubular body to receive a coupling that connects to one end of the cut pipe. A radially enlarged section on the spigot has a sealing mechanism that sealably engages an interior surface of the tubular body. The locking mechanism, engaged by collapsing the spigot into the tubular body or disengaged by extending the spigot therefrom, facilitates a push and twist connection at both ends of the pipe to wipe the adhesive disposed therebetween and obtain a better seal. Preferably, the locking mechanism comprises a socket having spigot engaging members that cooperatively engage socket engaging members on the spigot.

-

Articulated Soft Doll Construction Assembly

view source -

US Patent:46628576, May 5, 1987

-

Filed:Sep 27, 1985

-

Appl. No.:6/781299

-

Inventors:Gregory F. Quinn - Fullerton CA

Virgil W. Wulff - Fullerton CA

Robert F. Schroeder - Long Beach CA -

Assignee:Mattel, Inc. - Hawthorne CA

-

International Classification:A63H 302

A63H 346 -

US Classification:446371

-

Abstract:An articulated soft doll construction in which a soft skin covers a soft doll head and a soft skin covers a soft torso in which the head is universally moveable relative to the torso. The torso has a first skin cover covering a fiber filler material. The torso and first skin cover are formed with an opening in which a neck connecting member is received. A second soft skin cover is used to cover a soft head that is filled with fiber material. A neck plug is received through an opening in the head and second soft skin cover. Disposed inside a neck plug is a ball and socket assembly in which the ball is connected to a spindle member that extends into the torso and is received by the neck connecting member for engagement therewith. A collar member is received inside the neck plug for retaining the second soft skin cover around the head. A remaining member is received by the neck connecting member to retain the first soft skin cover.

-

Oil Filter Wrench And Packaging Therefor

view source -

US Patent:56068972, Mar 4, 1997

-

Filed:Dec 22, 1995

-

Appl. No.:8/577332

-

Inventors:Gregory F. Quinn - Fullerton CA

-

Assignee:FloTool International, Inc. - Tustin CA

-

International Classification:B25B 1300

B65D 7502 -

US Classification:811246

-

Abstract:A oil filter wrench and packaging arrangement therefore are disclosed. The oil filter wrench has a cup-shaped body with a socket formed therein for receiving the top of a conventional oil filter. The interior side wall has a step therein circumscribing the socket. The oil filter wrench can be packaged between a cardboard backing and plastic cover sheet such that the cover sheet over laps the rim of the cup-shaped body. The step spaces the plastic sheet from the socket, keeping the socket area open. With this packaging arrangement the consumer can try his oil filter with the wrench without destroying the package to determine whether the wrench suits his needs before purchasing it.

-

Container Closure Cap

view source -

US Patent:D3664180, Jan 23, 1996

-

Filed:Mar 28, 1994

-

Appl. No.:D/020518

-

Inventors:John M. Lown - Huntington Beach CA

Gregory F. Quinn - Fullerton CA

Robert P. Mayercheck - Irvine CA -

Assignee:FloTool International, Inc. - Tustin CA

-

US Classification:D 9449

Name / Title

Company / Classification

Phones & Addresses

Indieshack, LLC

Custom Computer Programing Business Services at Non-Commercial Site

Custom Computer Programing Business Services at Non-Commercial Site

9651 W Cyn Ter, San Diego, CA 92123

CINEMATIC HOMES LLC

Resumes

Gregory Quinn

view source

Gregory Quinn

view source

Gregory Quinn

view source

Gregory Quinn

view sourceLocation:

United States

Googleplus

Gregory Quinn

Gregory Quinn

Gregory Quinn

Gregory Quinn

Gregory Quinn

Gregory Quinn

Gregory Quinn

Gregory Quinn

Youtube

Myspace

Plaxo

Gregory Quinn Tiberend

view sourceNew York, NYPast: President & CEO at Tiberend Strategic Advisors Tiberend Strategic Advisors, Inc.

Life Sciences Group

Gregory Quinn

view sourceLas Vegas, NVCasino Porter at Wynn Las Vegas

Flickr

Classmates

Gregory Quinn

view sourceSchools:

North Haven Community High School North Haven ME 1996-2000

Community:

Diane Schnellhammer, Stacy Adams, Rick Winslow, Clare Winslow

Gregory Quinn

view sourceSchools:

St. Louis School Pittsford NY 1974-1983

Community:

Jeanne Bristol, James Demarco, Sue Missler

Gregory Quinn

view sourceSchools:

grover cleaveland highschool New York NY 1975-1979

Community:

Thomas Herberich

Gregory Quinn

view sourceSchools:

St. Vincent De Paul School Elmont NY 1962-1966

Community:

Rick Stroetz, Iris Marks, Ronald Pierse, Tom Orlando, Susan Thornton

Gregory Quinn | West Esse...

view source

Gregory Quinn | Aquinas M...

view source

Gregory Quinn | Hanover P...

view source

North Haven Community Hig...

view sourceGraduates:

Chris Emerson (1999-2003),

Mary Swanson (2000-2004),

Gregory Quinn (1996-2000),

Stanley Quinn (1965-1969)

Mary Swanson (2000-2004),

Gregory Quinn (1996-2000),

Stanley Quinn (1965-1969)

Gregory Quinn

view source

Gregory Quinn

view source

Gregory Quinn

view source

Gregory Quinn

view source

Gregory J Quinn

view source

Gregory Quinn

view source

Gregory Quinn

view source

Gregory Quinn

view sourceGet Report for Gregory A Quinn from Anaheim, CA, age ~64