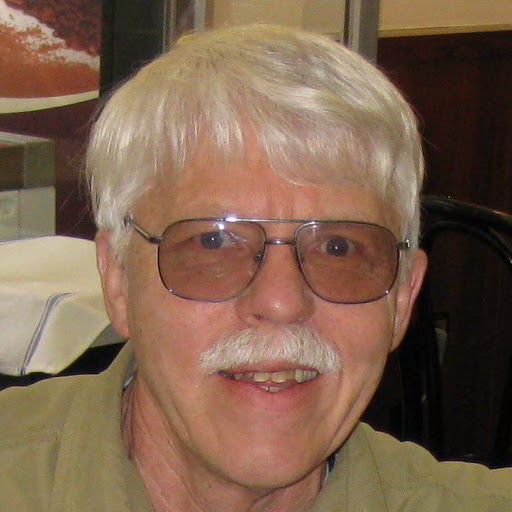

James P Colvin

age ~82

from Simi Valley, CA

- Also known as:

-

- James Patrick Colvin

- James P Coluin

- Jon Colvin

- Phone and address:

-

2395 Valley Terrace Dr, Simi Valley, CA 93065

8055824892

James Colvin Phones & Addresses

- 2395 Valley Terrace Dr, Simi Valley, CA 93065 • 8055824892 • 8053384041

- 6364 Raylene Ct, Simi Valley, CA 93063

- 2298 Oak Haven Ave, Simi Valley, CA 93063

- Ventura, CA

- 2395 Valley Terrace Dr, Simi Valley, CA 93065

Resumes

James Colvin

view source

James T Colvin

view source

James L Colvin

view sourceWork:

Abb

Major Retired

Major Retired

James Colvin

view source

James Colvin

view source

James Colvin

view source

James Colvin

view sourceLocation:

United States

James Colvin

view sourceLocation:

United States

Lawyers & Attorneys

James Colvin - Lawyer

view sourceSpecialties:

Commercial Litigation

Collections

Construction Law

Energy

Insurance Defense

Litigation

Civil Litigation

Complex Litigation

Medical Malpractice

Products Liability

Professional Liability

Trade Secrets

Business & Corporate

Employment

Trial Practice

Business & Corporate Law

Collections

Construction Law

Energy

Insurance Defense

Litigation

Civil Litigation

Complex Litigation

Medical Malpractice

Products Liability

Professional Liability

Trade Secrets

Business & Corporate

Employment

Trial Practice

Business & Corporate Law

ISLN:

918247658

Admitted:

2005

University:

University of Georgia, B.A., 2002

Law School:

University of Tulsa, J.D., 2004

Isbn (Books And Publications)

Name / Title

Company / Classification

Phones & Addresses

Chief Executive

Downtime Software

Eating Places

Eating Places

1621 Masthead Dr, Oxnard, CA 93035

President

FA INSTRUMENTS, INC

2381 Zanker Rd SUITE 100, San Jose, CA 95131

GREAT LAKES SPEEDSPORTS, L.L.C

President

JASMINE GLEN AT ROLLING HILLS HOMEOWNERS ASSOCIATION

2335 Vly Ter Dr, Simi Valley, CA 93065

President, Principal

Fa Instruments

Whol Electronic Parts/Equipment

Whol Electronic Parts/Equipment

2381 Zanker Rd, San Jose, CA 95131

Us Patents

-

Induction Heating Apparatus

view source -

US Patent:6608291, Aug 19, 2003

-

Filed:Mar 19, 2001

-

Appl. No.:09/811857

-

Inventors:Roberto A. Collins - San Jose CA 95123

James B. Colvin - Newark CA 94560 -

International Classification:H05B 608

-

US Classification:219662, 219663

-

Abstract:A portable induction heating system which utilizes a broadband high frequency high-power, low output impedance power generator formed from switching MOSFET devices. A voltage-controlled oscillator (VCO) or microprocessor-controlled signal generator drives a power output stage under feedback control so as to effectuate resonance at a high frequency in an induction coil assembly connected to the power generator. The power generator is operable with a switching regulator that can supply a fixed DC voltage, e. g. , 12 to 48 V or a variable setpoint. The induction coil assembly includes a capacitive circuit portion connected to a conductive coil that can couple magnetic field to a susceptor. A microcontroller is provided for inputting operating parameters such as power, frequency, duty cycle and duration, and is operable to auto-tune the VCO output under feedback control by sweeping frequency at startup as well as by controlling drift during operation under a changing load.

-

System And Method For Use In Functional Failure Analysis By Induced Stimulus

view source -

US Patent:7323888, Jan 29, 2008

-

Filed:Oct 18, 2004

-

Appl. No.:10/967808

-

Inventors:James B. Colvin - Newark CA, US

-

International Classification:G01R 31/302

G01R 31/305 -

US Classification:324751, 250310, 324752

-

Abstract:A scanning/imaging system wherein an external stimulus is used for exciting a device under test (DUT). A stimulus source is included for providing a stationary stimulus with a controllable spot size to a device under test (DUT), the controllable spot size covering a portion of the DUT for excitation by the stationary stimulus. A sensor is operable for capturing at least one of a functional response signal and an optical image signal emanating from the DUT portion. A linear positioning device is operable to facilitate scanning of remaining portions of the DUT until a predetermined area thereof has been traversed. A controller is operably coupled to the linear positioning device, stimulus source and the sensor for providing the overall control thereof.

-

System And Method For Use In Functional Failure Analysis By Induced Stimulus

view source -

US Patent:7872485, Jan 18, 2011

-

Filed:Jan 14, 2008

-

Appl. No.:12/013881

-

Inventors:James B. Colvin - Newark CA, US

-

International Classification:G01R 31/305

-

US Classification:32475423, 32475421

-

Abstract:A scanning/imaging system wherein an external stimulus is used for exciting a device under test (DUT). A stimulus source is included for providing a stationary stimulus with a controllable spot size to a device under test (DUT), the controllable spot size covering a portion of the DUT for excitation by the stationary stimulus. A sensor is operable for capturing at least one of a functional response signal and an optical image signal emanating from the DUT portion. A linear positioning device is operable to facilitate scanning of remaining portions of the DUT until a predetermined area thereof has been traversed. A controller is operably coupled to the linear positioning device, stimulus source and the sensor for providing the overall control thereof.

-

System And Method For Use In Functional Failure Analysis By Induced Stimulus

view source -

US Patent:8400175, Mar 19, 2013

-

Filed:Jan 18, 2011

-

Appl. No.:13/008375

-

Inventors:James B. Colvin - Newark CA, US

-

International Classification:G01R 31/305

-

US Classification:32475423, 32475421

-

Abstract:A scanning/imaging system wherein an external stimulus is used for exciting a device under test (DUT). A stimulus source is included for providing a stationary stimulus with a controllable spot size to a device under test (DUT), the controllable spot size covering a portion of the DUT for excitation by the stationary stimulus. A sensor is operable for capturing at least one of a functional response signal and an optical image signal emanating from the DUT portion. A linear positioning device is operable to facilitate scanning of remaining portions of the DUT until a predetermined area thereof has been traversed. A controller is operably coupled to the linear positioning device, stimulus source and the sensor for providing the overall control thereof.

-

System And Method For Gradient Thermal Analysis By Induced Stimulus

view source -

US Patent:20110115510, May 19, 2011

-

Filed:Nov 12, 2010

-

Appl. No.:12/945284

-

Inventors:James B. Colvin - Newark CA, US

-

International Classification:G01R 31/00

-

US Classification:32475003

-

Abstract:A thermal gradient is induced in a device-under-test (DUT) and used to determine the location of a defect. In one embodiment, a laser creates a moving thermal gradient from a test site on the DUT and a respective time of flight for the thermal gradient to trigger a condition associated with the defect is determined. Repeating the time of flight testing at additional test site provides information used to trilaterate the defect in three dimensions. Alternately, a static thermal gradient is induced across at least a portion of the DUT along a first axis. The thermal gradient is incrementally walked along the first axis until the condition associated with the defect is triggered, thereby defining a first region. The thermal gradient is then induced along a second axis of the DUT and the process is repeated to define a second region. The location of the defect is determined to be the intersection of the first region with the second region.

-

Apparatus And Method For Electronic Sample Preparation

view source -

US Patent:20130271169, Oct 17, 2013

-

Filed:Apr 10, 2013

-

Appl. No.:13/859902

-

Inventors:James B. Colvin - Newark CA, US

-

International Classification:G01R 1/44

-

US Classification:32475003

-

Abstract:A method and apparatus for preparing electronic samples for a subsequent treatment, e.g., application of a failure analysis treatment. In one embodiment, an electronic device is mounted on a thermally controlled plate and a select temperature is applied thereto. While maintaining the select temperature applied to the thermally controlled plate, a sample preparation process is performed on the electronic device, such as, e.g., performing polishing, thinning, milling, lapping or extracting one or more semiconductor dies that form the electronic device.

-

Apparatus And Method For Endpoint Detection During Electronic Sample Preparation

view source -

US Patent:20130273671, Oct 17, 2013

-

Filed:Apr 12, 2013

-

Appl. No.:13/861926

-

Inventors:James Barry Colvin - Newark CA, US

-

International Classification:H01L 21/66

-

US Classification:438 14, 324 72

-

Abstract:A method for detecting an endpoint during removal of material from an electronic device includes while removing material from an electronic device-under-test (DUT) using a tip driven by a spindle, applying an input signal to the DUT via the tip and using an output signal received from one of the DUT and a mounting plate to which the DUT is attached to determine an endpoint for removal of material.

-

Apparatus And Method For Endpoint Detection During Electronic Sample Preparation

view source -

US Patent:20130273674, Oct 17, 2013

-

Filed:Apr 12, 2013

-

Appl. No.:13/861981

-

Inventors:James Barry Colvin - Newark CA, US

-

International Classification:H01L 21/66

B23C 3/00

B24B 37/013 -

US Classification:438 17, 409133, 451 5

-

Abstract:An apparatus for endpoint detection during removal of material from an electronic component includes a mounting plate operable to provide physical and electrical attachment for a device-under-test (DUT), a spindle operable to hold a tip for removing material from the DUT, a signal generator operable to provide an input signal to a first electrode, and a microprocessor connected to use an output signal from a second electrode to terminate the removal of material when an endpoint is reached, the first electrode being one of the tip and the DUT and the second electrode being the opposite one of the tip and the DUT.

Plaxo

James Colvin

view source

James E. Colvin

view source

James Colvin

view sourceBirmingham, ALCEO/President at The ScoreCard Lounge

Classmates

James Colvin

view sourceSchools:

Bowie Elementary School Grand Prairie TX 1949-1954

Community:

Judy Davenport, Buddy Gabriel, Paul Sisson, Robert Truitt, Mike Holt

James Colvin

view sourceSchools:

Lakewood Elementary School Kalamazoo MI 1958-1962

Community:

Jennifer Kirk, Kimberly Bouma, Krystal Froats, Ray Austin, Victoria Polomcak

James Colvin (Colvin, Jr.)

view sourceSchools:

St. Jude Educational Institute High School Montgomery AL 1971-1975

Community:

Shenita Smith

James S. COLVIN Colvin

view sourceSchools:

Roosevelt Junior High School Compton CA 1944-1948

Community:

Robert Hilsabeck, Darlene Carter, Charlotte Holmes, Cecelia Johnson, Howard Jones

James Colvin (James Colvin)

view sourceSchools:

Lafayette High School 204 Buffalo NY 1987-1991

Community:

Louis Marconi, Johanna Kupco

James Colvin

view sourceSchools:

La Colima Elementary School Whittier CA 1992-1996

Community:

Debbie Bell, Richard Currier, Thea Vondracek

James Colvin

view sourceSchools:

Abrams High School Bessemer AL 1961-1965

Community:

Dwight Jones, Carolyn Martin, Reginald Hamilton

James Colvin

view sourceSchools:

Pickens County Training High School Carrollton AL 1962-1966

Community:

Constance Richey, Pamela Hood, Darrell Carr, Fannie Haney

Youtube

Myspace

Googleplus

James Colvin

Work:

La Frontera Center - Utilization Management Specialist (2010)

Education:

University of Arizona - Masters of Public Administration, University of Arizona - Bachelors of Public Health

James Colvin

Lived:

Camarillo, CA

Work:

Retired

Education:

University of California, Berkeley

James Colvin

James Colvin

James Colvin

James Colvin

James Colvin

James Colvin

James Joe Colvin

view source

James Colvin Sr.

view source

James Colvin

view source

James C. Colvin

view source

James Jimi Colvin

view source

James Earl Colvin

view source

James G. Colvin

view source

James Colvin Jr

view sourceFlickr

Get Report for James P Colvin from Simi Valley, CA, age ~82