James P Hadden

age ~76

from Midlothian, VA

- Also known as:

-

- James Patrick Hadden

- Phone and address:

- 3437 Robious Forest Way, Midlothian, VA 23113

James Hadden Phones & Addresses

- 3437 Robious Forest Way, Midlothian, VA 23113

- Raleigh, NC

- Evergreen, CO

- Tipp City, OH

- Evergreen, CO

Work

-

Position:Service Occupations

Education

-

Degree:Graduate or professional degree

Emails

Resumes

James Hadden

view source

James Hadden

view sourceLocation:

United States

License Records

James R Hadden

License #:

E127418 - Active

Category:

Emergency medical services

Issued Date:

Jan 19, 2017

Expiration Date:

Jan 31, 2019

Type:

Alameda County EMS Agency

James Daniel Hadden Dds

License #:

7086 - Active

Category:

Dentistry

Issued Date:

May 15, 2013

Effective Date:

May 15, 2013

Expiration Date:

Mar 1, 2019

Type:

Dentist

James Joji Hadden

License #:

A5191019

Category:

Airmen

Isbn (Books And Publications)

Hadden's Journal and Orderly Books: A Journal Kept in Canada and upon Burgoyne's Campaign in 1776 and 1777

view sourceAuthor

James Murray Hadden

ISBN #

0836954629

Modern Musicians: A Book for Players, Singers and Listeners

view sourceAuthor

James Cuthbert Hadden

ISBN #

0722252528

Name / Title

Company / Classification

Phones & Addresses

Vice President

Avid Construction Incorporated

Avid Construction Incorporated. Dream Construction Inc.

Remodeling Services

Avid Construction Incorporated. Dream Construction Inc.

Remodeling Services

6905 Broadway, Denver, CO 80221

3034274927, 3034264925

3034274927, 3034264925

Vice President

Avid Construction Incorporated

Remodeling Services

Remodeling Services

6905 Broadway, Denver, CO 80221

3034274927, 3034264925

3034274927, 3034264925

Manager

Avid Consttruction Inc

Trade Contractor

Trade Contractor

6905 Broadway, Denver, CO 80221

3034274927

3034274927

Newtech Associates, Inc

8416 Neuse Rpd Rd, Raleigh, NC 27616

PO Box 61116, Raleigh, NC 27661

PO Box 61116, Raleigh, NC 27661

COLUMBUS BELLERIA, LLC

OHIO JOBS PARTNERSHIP LLC

COUGHLIN 42 LLC

PRH CONSULTING GROUP, LLC

Us Patents

-

Method Of Preparing Low Fat Meat Products

view source -

US Patent:52865142, Feb 15, 1994

-

Filed:Feb 10, 1993

-

Appl. No.:8/015911

-

Inventors:Neil B. Webb - Raleigh NC

James P. Hadden - Raleigh NC

Ta Chung Wu - Raleigh NC -

Assignee:Webb Technical Group, Inc. - Raleigh NC

-

International Classification:A23L 1317

-

US Classification:426646

-

Abstract:This invention is a process for producing low fat meat products comprising trimming the meat to no more than 11%, by weight, fat, cooling the meat to approximately 40 degrees Fahrenheit, comminuting the meat to approximately 3/8 inch particle size, mixing between 0. 5 and 5. 0%, by weight, oat bran and betwen 0. 3 and 3. 0%, by weight flavoring with the comminuted meat, and comminuting the resulting mixture to between 3/16 inch and 1/8 inch particle size to produce a low fat meat product that, when cooked, has the mouth-feel, texture, juiciness and tenderness of normal fat comminuted meat products.

-

Use Of Acid As An Analysis Aid In Salted Meat Samples

view source -

US Patent:42664233, May 12, 1981

-

Filed:Oct 1, 1979

-

Appl. No.:6/080841

-

Inventors:James P. Hadden - Tipp City OH

-

Assignee:Hobart Corporation - Troy OH

-

International Classification:G01N 504

-

US Classification:73 15B

-

Abstract:The accurate determination of the fat, moisture, and protein content of salt added meats by means of thermal extraction is complicated by the enhanced fat and moisture binding capability that salt gives to meat proteins. This effect is counteracted by the addition of a controlled amount of acid to a salted meat sample which lowers the pH of the meat proteins below their isoelectric points. In a preferred embodiment, citric acid is mixed with a salted meat sample and the sample is then exposed to microwave energy for a time sufficient to achieve a relatively constant chemical analysis in the residue which is related to the amount of fat and moisture rendered from the sample.

-

Low Hot Water Volume Warewasher

view source -

US Patent:44392427, Mar 27, 1984

-

Filed:Oct 18, 1982

-

Appl. No.:6/435019

-

Inventors:James P. Hadden - Tipp City OH

-

Assignee:Hobart Corporation - Troy OH

-

International Classification:B08B 302

-

US Classification:134 252

-

Abstract:A rack-type high capacity warewashing machine is designed to cleanse and sanitize foodware in a cycle time of the order of one minute and to accomplish sanitizing by heating the foodware with fresh hot water sufficiently to kill residual bacteria thereon. The method of operation of the machine includes a final rinse period in which fresh water at a temperature of at least 180. degree. F. (82. 22. degree. C. ) is sprayed over the foodware to remove residual soil and to heat the foodware surfaces to at least 160. degree. F. (71. 11. degree. C. ), followed by a dwell period in which the wet heated foodware is maintained in a substantially closed humid atmosphere to prolong the time during which the foodware surfaces remain above bacteria killing temperature and to cause a build-up of Heat Unit Equivalents to at least 3600.

Plaxo

James Hadden

view sourceThe Bommarito Group

Classmates

James Hadden

view sourceSchools:

Mill River Union High School North Clarendon VT 1989-1993

Community:

Judie Weeden

James Hadden

view sourceSchools:

Ellen Woodside High School Piedmont SC 1961-1965

Community:

Donnie Garett, Mary Cothran

James Hadden

view sourceSchools:

caslemont high school Oakland CA 1981-1985

Community:

Shirley Mcleod

James Hadden

view sourceSchools:

Lawrence County High School Monticello MS 2001-2005

Community:

Laura Young, Jacqueline Price

James Hadden

view sourceSchools:

Misawa/Edgren High School Misawa Air Base PA 1985-1989

Community:

William Amos, Nancy Edgar, Jim Thornber, Kimberly Wiar

James Hadden

view sourceSchools:

Westwood Christian School Miami FL 1970-1974, Leewood Elementary School Miami FL 1974-1978, Frank C. Martin Elementary School Miami FL 1979-1979, C. T. Sewell Elementary School Henderson NV 1979-1980, Helen C. Cannon Junior High School Las Vegas NV 1980-1981, Pasco Junior High School Dade City FL 1981-1981

Community:

Sandra High, Glenda Swilley

James Hadden

view sourceSchools:

West Canada Valley High School Newport NY 1972-1976

James Hadden

view sourceSchools:

Otego High School Otego NY 1959-1963

Community:

Karen Coote, Loretta Pearce

Youtube

Myspace

Googleplus

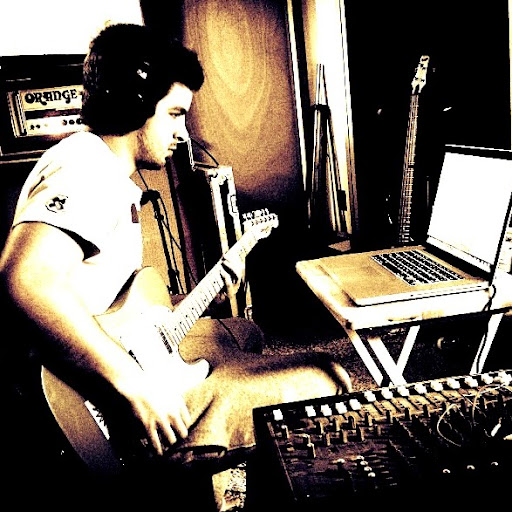

James Hadden

About:

From Wyoming, loves playing music, frisbees, and other outdoor things.

Tagline:

Musician and photographer

James Hadden

Tagline:

I am man, but a woman made this. That photo of a cat is the womans cat. I made her make this account for all my sixties music video needs. Thank you.

James Hadden

James Hadden

James Hadden

James Hadden

James Hadden

James Hadden

Work:

Challenger Homes - Personal Builder

James Hadden Jr.

view source

James Hadden

view source

James Hadden Jr.

view source

James Hadden

view source

James Hadden

view source

James Hadden II

view source

James Hadden

view source

James Hadden

view sourceFlickr

Get Report for James P Hadden from Midlothian, VA, age ~76