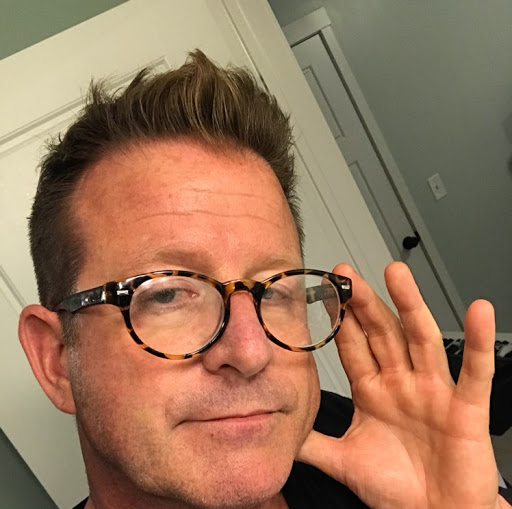

Jeffrey Todd Hastings

age ~49

from Lexington, KY

- Also known as:

-

- Jeffrey T Hastings

- Todd J Hastings

- Jtodd Hastings

- Tod D Hastings

- Hastings J Todd

- Phone and address:

-

609 Centennial Ln, Lexington, KY 40502

8592662673

Jeffrey Hastings Phones & Addresses

- 609 Centennial Ln, Lexington, KY 40502 • 8592662673

- 356 Cassidy Ave, Lexington, KY 40502

- 101 Hanover Ave, Lexington, KY 40502

- Cambridge, MA

- 305 Memorial Dr, Cambridge, MA 02139

Work

-

Position:Private Household Service Occupations

Education

-

Degree:Graduate or professional degree

Resumes

Jeffrey Hastings

view sourceWork:

City Houston Animal Control

Education:

Sterling High School

Skills:

Management

Leadership

Staff Development

Team Building

Microsoft Office

Leadership

Staff Development

Team Building

Microsoft Office

Jeffrey Hastings

view source

Hotel Services Manager At Quest Cleaners

view sourceLocation:

Greater Boston Area

Industry:

Hospitality

Medicine Doctors

Jeffrey Hastings

view sourceSpecialties:

Cardiovascular Disease

Work:

Dallas VA Medical Center Cardiology

4500 S Lancaster Rd FL 5, Dallas, TX 75216

2148571472 (phone), 2143021341 (fax)

4500 S Lancaster Rd FL 5, Dallas, TX 75216

2148571472 (phone), 2143021341 (fax)

Education:

Medical School

University of Texas Southwestern Medical Center at Dallas

Graduated: 2003

University of Texas Southwestern Medical Center at Dallas

Graduated: 2003

Procedures:

Cardiac Rehabilitation

Cardiac Stress Test

Cardioversion

Echocardiogram

Electrocardiogram (EKG or ECG)

Cardiac Stress Test

Cardioversion

Echocardiogram

Electrocardiogram (EKG or ECG)

Conditions:

Acute Myocardial Infarction (AMI)

Atrial Fibrillation and Atrial Flutter

Heart Failure

Ischemic Heart Disease

Acute Renal Failure

Atrial Fibrillation and Atrial Flutter

Heart Failure

Ischemic Heart Disease

Acute Renal Failure

Languages:

English

French

Spanish

French

Spanish

Description:

Dr. Hastings graduated from the University of Texas Southwestern Medical Center at Dallas in 2003. He works in Dallas, TX and specializes in Cardiovascular Disease.

Us Patents

-

System And Method For Fabrication And Replication Of Diffractive Optical Elements For Maskless Lithography

view source -

US Patent:7348104, Mar 25, 2008

-

Filed:Oct 2, 2003

-

Appl. No.:10/677173

-

Inventors:Dario Gil - Cambridge MA, US

Jeffrey T. Hastings - Cambridge MA, US

James G. Goodberlet - Melrose MA, US

Rajesh Menon - Boston MA, US

David J. Carter - Cambridge MA, US

Henry I. Smith - Sudbury MA, US -

Assignee:Massachusetts Institute of Technology - Cambridge MA

-

International Classification:G02B 27/44

G02B 27/42

G02B 5/18 -

US Classification:430 4, 430 11, 430394, 359558, 359565, 359573

-

Abstract:A method is disclosed for forming an array of focusing elements for use in a lithography system. The method involves varying an exposure characteristic over an area to create a focusing element that varies in thickness in certain embodiments. In further embodiments, the method includes the steps of providing a first pattern via lithography in a substrate, depositing a conductive absorber material on the substrate, applying an electrical potential to at least a first portion of the conductive absorber material, leaving a second portion of the conductive material without the electrical potential, and etching the second portion of the conductive material to provide a first pattern on the substrate that is aligned with the first portion of the conductive absorber material.

-

Spatial-Phase Locking Of Energy Beams For Determining Two-Dimensional Location And Beam Shape

view source -

US Patent:7417234, Aug 26, 2008

-

Filed:May 17, 2005

-

Appl. No.:11/130892

-

Inventors:Jeffrey T. Hastings - Lexington KY, US

James G. Goodberlet - Melrose MA, US

Feng Zhang - Cambridge MA, US

Henry I. Smith - Sudbury MA, US -

Assignee:Massachusetts Institute of Technology - Cambridge MA

-

International Classification:H01J 37/304

-

US Classification:250397, 250396 R, 2504911, 2504922, 25049223, 25049221

-

Abstract:A method or system of spatial-phase locking a beam used in maskless lithography provides a fiducial grid with a single spatial-period, the fiducial grid being rotated at an angle with respect to a direction of scanning the beam; detects a signal generated in response to the beam being incident upon the fiducial grid; determines frequency components of the detected signal; and determines a two-dimensional location of the beam from phases of two determined fundamental frequency component. The method or system further determines a size of the beam from relative amplitudes of the determined fundamental and harmonic frequency components and/or determine a shape of the beam from relative amplitudes of the determined fundamental and harmonic frequency components. The method or system corrects a deflection of the beam in response to the determined two-dimensional location, and/or adjusts the size of the beam in response to the determined size, and/or adjusts the shape of the beam in response to the determined shape. If the method or system spatial-phase locks a plurality of beams used in maskless lithography, a fiducial grid with a varying spatial-period is utilized.

-

Dynamic Alignment Monitoring System For On-Vehicle Disk Brake Lathe

view source -

US Patent:7861625, Jan 4, 2011

-

Filed:Oct 24, 2008

-

Appl. No.:12/257429

-

Inventors:Christopher L. Greenwald - Waban MA, US

Jeffrey P. Hastings - Hanover NH, US -

Assignee:Pro-Cut Licensing Company, LLC - West Lebanon NH

-

International Classification:B23B 25/06

B23B 5/04 -

US Classification:82112, 82118

-

Abstract:A dynamic alignment monitoring system allows an operator to monitor the misalignment of an on-vehicle disk brake lathe with respect to a vehicle axis about which the disk to be machined rotates, and can allow the operator to discontinue further alignment when appropriate in order to speed the overall time of the alignment process. The system processes signals from an angular rate sensor and a tachometer, using a scaling routine to derive a LRO value corresponding to the LRO of the disk which would result from machining in the current alignment condition. A representation of the derived LRO value is displayed to the operator. An operator override can allow the operator to discontinue further alignment adjustments when an acceptable alignment condition is indicated. The system can aid the operator by also presenting a representation of an acceptable LRO value for the particular vehicle being serviced.

-

Reporting System For On-Vehicle Brake Lathe

view source -

US Patent:8245609, Aug 21, 2012

-

Filed:Feb 3, 2010

-

Appl. No.:12/699091

-

Inventors:Christopher L. Greenwald - Waban MA, US

Jeffrey P. Hastings - Hanover NH, US -

Assignee:Pro-Cut Licensing Company, LLC - West Lebanon NH

-

International Classification:B23B 5/04

B23B 1/00 -

US Classification:82112, 82 111, 82 47, 82118

-

Abstract:A reporting system, employing a microprocessor, tracks the operation of an on-vehicle brake lathe and provides records of the resurfacing operations performed by the lathe. Identification of the vehicle and wheel position of a brake disk to be resurfaced are inputted using an operator interface, and stored in a temporary memory. When tool bits of the lathe are positioned to set a depth of cut, a thickness monitor indicates the resulting thickness for the brake disk, which is compared to a minimum thickness specification for the inputted vehicle and wheel position to determine whether the disk can be resurfaced to meet the specification. If so, a cutting operation evaluator monitors a continuity checker that is responsive to contact of the tool bits and the disk to determine when the resurfacing operation is complete, at which time the collected data can be reported.

-

Optical Waveguide With Non-Uniform Sidewall Gratings

view source -

US Patent:20040037503, Feb 26, 2004

-

Filed:May 28, 2003

-

Appl. No.:10/446245

-

Inventors:Jeffrey Hastings - Lexington KY, US

Michael Lim - Cambridge MA, US

Henry Smith - Sudbury MA, US -

International Classification:G02B006/34

G02B006/10 -

US Classification:385/037000, 385/130000

-

Abstract:A diffraction grating of non-uniform strength is introduced into an optical waveguide by modulating its width. The waveguide may be fabricated using one of several planar processing techniques. Varying the size, position, and/or thickness of the grating teeth provides the desired variation of grating strength. Certain functional variations of grating strength suppress side-lobe levels in the grating reflection and transmission spectra. This process, termed apodization, is necessary for precise wavelength filtering and dispersion compensation. If desired, different periodicity gratings can be introduced in each side of the waveguide, multiple periodicities can be superimposed, the grating can be angled with respect to the waveguide, and the grating period and phase can be varied.

-

System, Device, And Method For Determination Of Intraocular Pressure

view source -

US Patent:20110160561, Jun 30, 2011

-

Filed:Dec 30, 2010

-

Appl. No.:12/982110

-

Inventors:Jeffrey Todd Hastings - Lexington KY, US

E. Britt Brockman - Louisville KY, US

Ingrid L. St. Omer - Lexington KY, US

John C. Wright - Louisville KY, US -

Assignee:BROCKMAN HOLDINGS LLC - Louisville KY

THE UNIVERSITY OF KENTUCKY RESEARCH FOUNDATION - Lexington KY -

International Classification:A61B 3/16

-

US Classification:600398

-

Abstract:A system for determination of intraocular pressure includes: an intraocular pressure sensor; a light source illuminating the sensor with one or more wavelengths of light; and a detector that measures emitted light from the sensor. The sensor includes a substrate member, a spacer member, and a flexible membrane, which define a sealed cavity. The flexible membrane moves in response to intraocular pressure changes. A device for measuring intraocular pressure includes: the sensor; an anchoring member attached to the sensor for immobilizing the sensor in an eye; and a protective member attached to the anchoring member and covering the sensor to prevent contact between the flexible membrane and the eye. A method for determination of intraocular pressure includes: placing the sensor in an eye; illuminating, with a light source, the sensor with one or more wavelengths of light; and detecting, with a detector, a resultant light that contains information about intraocular pressure.

-

Particle-Beam Induced Processing Using Liquid Reactants

view source -

US Patent:20110293847, Dec 1, 2011

-

Filed:May 28, 2010

-

Appl. No.:12/789457

-

Inventors:Jeffrey Todd Hastings - Lexington KY, US

-

International Classification:C23F 17/00

C23C 14/14

C23C 14/06 -

US Classification:427524, 427523, 427527, 427531

-

Abstract:A system or method of charge particle beam induced materials processing is disclosed. A charged particle beam (electron or ion) is focused at the interface of a substrate and a bulk liquid. The beam induces a localized chemical reaction that results in deposition or etching of deterministic micro- or nano-scale structures. The bulk liquid reactants permit the deposition and etching of metals, semiconductors, and insulators. A charged particle transparent membrane separates the liquid reactant from the vacuum chamber in which the beam is transmitted. In many cases, bulk liquid reactants permit processing of materials with much higher purity that of the prior art and permit processing of materials previously unavailable in charged particle beam processes.

-

Device For Securing Additional Devices In An Eye Without Interfering With Vision

view source -

US Patent:20210298946, Sep 30, 2021

-

Filed:Dec 31, 2020

-

Appl. No.:17/139205

-

Inventors:- Lexington KY, US

Jeffrey Todd Hastings - Lexington KY, US

Carlos Andres Jarro - Lexington KY, US

James L. Russell - Lexington KY, US -

International Classification:A61F 9/00

A61B 3/16

A61B 5/145

A61B 3/02

A61B 5/00 -

Abstract:An eye implantation device has a body including a support system adapted to engage at three points with an iridocorneal angle of an anterior chamber of an eye into which the device is implanted.

Isbn (Books And Publications)

Shirley And Silly Sam: In the Land of the Lost Squirrels

view sourceAuthor

Jeffrey Hastings

ISBN #

0595365825

Name / Title

Company / Classification

Phones & Addresses

MILLBROOK PROPERTIES, LLC

Myspace

Googleplus

Jeffrey Hastings

Work:

School Library Journal/SLJ.com/Digital Shift - Columnist

Howell Public Schools - Teacher

Howell Public Schools - Teacher

Education:

University at Buffalo, The State University of New York, Buffalo State College, University of Phoenix, Spring Arbor University, Michigan State University

Tagline:

I'm an extremely handsome, utterly brilliant and incredibly accomplished pathological liar.

Bragging Rights:

I've been around the block a couple of times.

Jeffrey Hastings

Work:

APTAR - Material handler (2013)

Education:

Harvard high school

Jeffrey Hastings

Jeffrey Hastings

Jeffrey Hastings

Jeffrey Hastings

Jeffrey Hastings

Jeffrey Hastings

Classmates

Jeffrey Hastings

view sourceSchools:

Garfield High School Terre Haute IN 1965-1969

Community:

Charlie Barth, John Smith, Luann King

Jeffrey Hastings

view sourceSchools:

Kossuth High School Kossuth MS 2002-2006

Community:

Shirley Woods, Sarah Dilworth, Don Anderson

Jeffrey Hastings

view sourceSchools:

Biggersville Elementary School Corinth MS 1975-1979

Community:

Michael Bo, Willene Hunnewell, Willene Carpenter, Kristie Fiveash, Cathy Sanders

Jeffrey Hastings

view sourceSchools:

Elverado High School Elkville IL 1975-1979

Community:

Steve Cobin, John Rowland

Jeffrey Hastings

view sourceSchools:

Doniphan High School Doniphan NE 1986-1990

Community:

Billy Gregg, Shauna Coffin, Russ Cochell, Karen Shultz, Jon Thomas, Barbra Brandon, Robin Zalud, Stacy Dreesen, Eric Paczosa

Jeffrey Hastings | Lake P...

view source

Jeffrey Hastings | Merril...

view source

Doniphan High School, Don...

view sourceGraduates:

Jeff Whitaker (1980-1984),

Danny Hastings (1981-1985),

Jeffrey Hastings (1986-1990),

James Rainforth (1993-1997)

Danny Hastings (1981-1985),

Jeffrey Hastings (1986-1990),

James Rainforth (1993-1997)

Jeffrey Hastings

view source

Jeffrey Hastings

view source

Jeffrey Hastings

view source

Jeffrey Hastings

view source

Jeffrey Hastings

view source

Jeffrey Hastings

view source

Jeffrey H. Hastings

view source

Jeffrey Gene Hastings

view sourceFlickr

Youtube

News

The Campaign of Hillary and Mrs. Clinton

view source- trail her small motorcade across the Granite State. On Monday, U.S. politics editor David Martosko and a photographer traveling with him, Jeffrey Hastings, caught the Scooby van going 92 miles per hour in a 65 mph zone on Interstate Highway 89. The Drudge Report linked to the story within minutes.

- Date: Apr 26, 2015

- Category: U.S.

- Source: Google

Democrats, Republicans lawyer-up for US election

view source- There will be up to 7,000 observers as well as the 4,000 election workers at polling station in Cuyahoga county, the most populous county in the key state of Ohio, said Jeffrey Hastings, chairman of the Cuyahoga Board of Elections.

- Date: Nov 04, 2012

- Source: Google

Get Report for Jeffrey Todd Hastings from Lexington, KY, age ~49