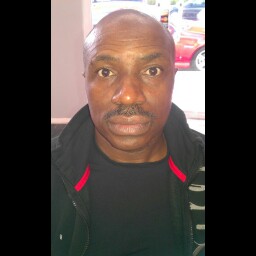

Jeffrey O Short

age ~62

from Fort Washington, MD

- Also known as:

-

- Jeffrey D Short

- Jeffery O Short

- Jeff O Short

- Jeffrey O'Short

- Phone and address:

-

904 Raad Ct, Fort Washington, MD 20744

3012925524

Jeffrey Short Phones & Addresses

- 904 Raad Ct, Ft Washington, MD 20744 • 3012925524 • 8479106145

- Fort Washington, MD

- Chicago, IL

- Alexandria, VA

- Accokeek, MD

- Bordentown, NJ

- College Park, MD

- 904 Raad Ct, Fort Washington, MD 20744 • 3012925524

Work

-

Position:Administration/Managerial

Education

-

School / High School:State University of New York At Buffalo

Languages

English

Awards

Healthgrades Honor Roll

Ranks

-

Certificate:Aerospace Medicine, 2009

Emails

Specialities

Emergency Medicine • Aerospace Medicine • Preventive Aerospace Medicine

Vehicle Records

-

Jeffrey Short

view source -

Address:904 Raad Ct, Fort Washington, MD 20744

-

Phone:3012923877

-

VIN:WDBUF56X37B044203

-

Make:MERCEDES-BENZ

-

Model:E-CLASS

-

Year:2007

Medicine Doctors

Dr. Jeffrey E Short, Fort George G Meade MD - MD (Doctor of Medicine)

view sourceSpecialties:

Emergency Medicine

Aerospace Medicine

Preventive Aerospace Medicine

Aerospace Medicine

Preventive Aerospace Medicine

Address:

4533 Butler St, Fort George G Meade, MD 20755

4103050232 (Phone), 4103050232 (Fax)

4103050232 (Phone), 4103050232 (Fax)

Certifications:

Aerospace Medicine, 2009

Emergency Medicine, 1993

Emergency Medicine, 1993

Awards:

Healthgrades Honor Roll

Languages:

English

Education:

Medical School

State University of New York At Buffalo

Medical School

Tripler Army Med Center

Graduated: 1986

Medical School

Brooks Afb

Graduated: 1998

Medical School

Madigan Amc

Graduated: 1992

State University of New York At Buffalo

Medical School

Tripler Army Med Center

Graduated: 1986

Medical School

Brooks Afb

Graduated: 1998

Medical School

Madigan Amc

Graduated: 1992

Jeffrey K. Short

view sourceSpecialties:

Diagnostic Radiology, Vascular & Interventional Rad

Work:

Charleston RadiologistsCharleston Radiologists PA

1241 Woodland Ave, Mount Pleasant, SC 29464

8438240606 (phone), 8438240909 (fax)

1241 Woodland Ave, Mount Pleasant, SC 29464

8438240606 (phone), 8438240909 (fax)

Education:

Medical School

Medical University of South Carolina College of Medicine

Graduated: 1988

Medical University of South Carolina College of Medicine

Graduated: 1988

Languages:

English

Description:

Dr. Short graduated from the Medical University of South Carolina College of Medicine in 1988. He works in Mount Pleasant, SC and specializes in Diagnostic Radiology and Vascular & Interventional Rad. Dr. Short is affiliated with Colleton Medical Center, Summerville Medical Center and Trident Medical Center.

Jeffrey Edward Short M.P.H.

view sourceSpecialties:

Emergency Medicine

Aerospace Medicine

Aerospace Medicine

Education:

State University of New York at Buffalo (1985)

License Records

Jeffrey W Short

License #:

19639 - Active

Issued Date:

Apr 22, 1999

Expiration Date:

Jun 30, 2018

Type:

Certified Public Accountant

Jeffrey James Short

License #:

RAD02222 - Active

Category:

Radiologic Technology

Issued Date:

Sep 19, 2011

Expiration Date:

Jul 31, 2017

Type:

Radiographer

Jeffrey James Short

License #:

RAD02222 - Active

Category:

Radiologic Technology

Issued Date:

Sep 19, 2011

Expiration Date:

Jul 31, 2017

Type:

Radiographer

Us Patents

-

High Speed Method And Apparatus For Producing Foundry Molds

view source -

US Patent:40362779, Jul 19, 1977

-

Filed:Oct 17, 1975

-

Appl. No.:5/623411

-

Inventors:Kent Woonton - Kitchner, CA

Jeffrey R. Short - Lincolnshire IL

Kenneth N. Roach - Willowdale, CA -

Assignee:J. R. Short Milling Co. - Chicago IL

-

International Classification:B22C 1508

-

US Classification:164 16

-

Abstract:In the production of foundry mold parts by the method described in U. S. Pat. No. 3,739,834, the production rate is increased by employing a foundry sand mix which can be cured by means of a gaseous curing agent and carrying out curing of the pressed mold part while the mold part is supported at the pressing station.

-

Process For Producing Nixtamal And Masa Flour

view source -

US Patent:60250119, Feb 15, 2000

-

Filed:Jun 9, 1997

-

Appl. No.:8/871672

-

Inventors:Raleigh J. Wilkinson - Lockport IL

Jeffrey R. Short - Lincolnshire IL -

Assignee:J. R. Short Milling Company - Chicago IL

-

International Classification:A21D 200

-

US Classification:426622

-

Abstract:Whole kernel corn is ground and sifted to separate a coarse particle fraction which is then heated with lime and water to a temperature of at least 71. degree. C. and below 100. degree. C. , preferably about 99. degree. C. or less, for up to about 15 minutes. A fine particle fraction from the sifting step can be combined with the heat treated coarse fraction. The resulting heat treated mixture is then dried under a vacuum while continuously mixing for at least about 20 minutes to obtain a dried masa flour having a moisture content of about 7% to about 12% by weight. Thereafter, the dried masa flour can be ground while maintaining the temperature below the gelatinization temperature to reduce the particle size of the masa flour without further gelatinization.

-

Apparatus For Making Foundry Moulds

view source -

US Patent:RE299197, Feb 27, 1979

-

Filed:Feb 22, 1977

-

Appl. No.:5/771007

-

Inventors:Kent Woonton - Kitchner, CA

Jeffrey R. Short - Lincolnshire IL

Kenneth N. Roach - Willowdale, CA -

Assignee:J. R. Short Milling Company - Chicago IL

-

International Classification:B22C 1502

-

US Classification:164161

-

Abstract:Apparatus for continuous, high speed production of foundry mould parts by pressing them from a continuous bed of foundry sand mix which is based on a curable binder, pressing of the part being carried out at a time when the mix has adequate plastic flowability for pressure moulding and adequate potential curability to assure a strong, rigid cured product. Advantageous embodiments include curing means operating in conjunction with the pressing means.

Resumes

Jeffrey Short

view sourceLocation:

Washington, DC

Industry:

Financial Services

Skills:

Salesforce.com

Public Relations

Document Management

Cloud Computing

E Commerce

Seo

Sales Process

Solution Selling

Saas

Account Management

B2B

New Business Development

Lead Generation

Direct Sales

Cross Functional Team Leadership

Team Building

Management

Selling

Leadership

Crm

Team Leadership

Product Marketing

Start Ups

Product Management

Strategic Planning

Strategic Partnerships

Sales Management

Product Development

Strategy

Competitive Analysis

Enterprise Software

Marketing

Sales Presentations

Business Development

Sales Operations

Executive Management

Cold Calling

Sales

P&L Management

Customer Retention

Contract Negotiation

Public Relations

Document Management

Cloud Computing

E Commerce

Seo

Sales Process

Solution Selling

Saas

Account Management

B2B

New Business Development

Lead Generation

Direct Sales

Cross Functional Team Leadership

Team Building

Management

Selling

Leadership

Crm

Team Leadership

Product Marketing

Start Ups

Product Management

Strategic Planning

Strategic Partnerships

Sales Management

Product Development

Strategy

Competitive Analysis

Enterprise Software

Marketing

Sales Presentations

Business Development

Sales Operations

Executive Management

Cold Calling

Sales

P&L Management

Customer Retention

Contract Negotiation

Manager Of Business Development

view sourceLocation:

620 Prairie Ave, Barrington, IL 60010

Industry:

Financial Services

Work:

Cboe

Manager of Business Development

Manager of Business Development

Education:

Southwest College 1976 - 1978

Skills:

Derivatives

Trading

Options

Equities

Electronic Trading

Securities

Trading Systems

Series 7

Risk Management

Equity Derivatives

Finra

Financial Markets

Hedge Funds

Investments

Equity Trading

Trading Strategies

Trading

Options

Equities

Electronic Trading

Securities

Trading Systems

Series 7

Risk Management

Equity Derivatives

Finra

Financial Markets

Hedge Funds

Investments

Equity Trading

Trading Strategies

Jeffrey Short

view sourceName / Title

Company / Classification

Phones & Addresses

PAR TRACK STRIPING, LLC

BLUE RIBBON CARPENTRY AND TILE, LLC

WAY OUT GOLFER, LLC

GREENER ADVENTURES TOURS & TRAVEL, LLC

PATRIOT SERVICES, LLC

Jeffrey Short MD,MPH

Emergency Medicine

Emergency Medicine

4533 Butler St, Fort George G Meade, MD 20755

4103050232

4103050232

Director

Atlantic III at The Point Condominium Association, Inc

President, Treasurer

WEATHER DATA SERVICES, INC

Myspace

Youtube

Plaxo

Short, Jeffrey

view sourceWashington, DC Meto AreaVice President of Sales Banking/Credit Union Marke...

Jeffrey Short

view sourceScientific Games

Classmates

Jeffrey Short

view sourceSchools:

West Mesquite High School Mesquite TX 1995-1999

Jeffrey Short

view sourceSchools:

Knott County Central High School Hindman KY 1976-1980

Jeffrey Short

view sourceSchools:

Castle High School Newburgh IN 1975-1979

Community:

Penny Hagedorn, Bridgette Coon

Jeffrey Short

view sourceSchools:

Gorham-Fayette High School Fayette OH 1974-1978

Community:

Lyn Liechty

Jeffrey Short

view sourceSchools:

Enfield Academy Whitakers NC 1976-1980

Community:

Douglas Pickette, Jeffery Davis, Adam Waters, David Harris, Arthur Whitehead

Jeffrey Short

view sourceSchools:

DELCASTLE TECHNICHL HIGH SCHOOL Newport DE 1990-1994

Community:

Charlie Walling, Judie Watson, Michael Otoole

Jeffrey Short

view sourceSchools:

Oklahoma Baptist Shawnee OK 1972-1976

Community:

Ej Holt, Kennneth Fletcher, Robbie Elliott, Kim Hawkins, Christie Bello, Kim Stephens, Howard Craig, Jeff Short, Dee Lewis, Michael Trent

Jeffrey Short | Merritt I...

view sourceGoogleplus

Jeffrey Short

Work:

Beth Gaines - Campaign Manager (2012)

Assdemblywoman Beth Gaines - Field Representative (2011)

California State Senate Repbulican Caucus - Intern (2011-2011)

Oregon State Senate Republican Caucus - Intern (2011-2011)

Oregon State Representative Bill Kennemer - Legislative Assistant (2009-2010)

Oregon State Representative Bill Kennemer - Intern (2009-2009)

Assdemblywoman Beth Gaines - Field Representative (2011)

California State Senate Repbulican Caucus - Intern (2011-2011)

Oregon State Senate Republican Caucus - Intern (2011-2011)

Oregon State Representative Bill Kennemer - Legislative Assistant (2009-2010)

Oregon State Representative Bill Kennemer - Intern (2009-2009)

Education:

Willamette University - Politics

Jeffrey Short

Jeffrey Short

Jeffrey Short

Jeffrey Short

Jeffrey Short

Jeffrey Short

Jeffrey Short

Jeffrey Short

view source

Jeffrey Short

view source

Jeffrey Short

view source

Jeffrey Short Gignac

view source

Jeffrey Short

view source

Jeffrey Short

view source

Jeffrey R. Short

view source

Jeffrey Short

view sourceGet Report for Jeffrey O Short from Fort Washington, MD, age ~62