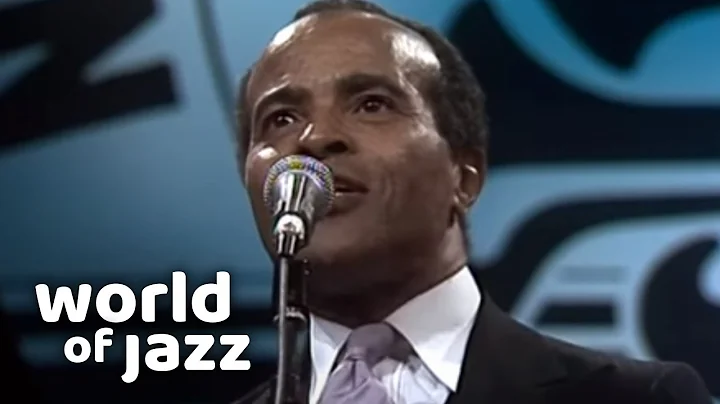

Joseph C Hendricks

age ~30

from Cabot, AR

- Also known as:

-

- Joseph Carlton Hendricks

- Joseph S Hendricks

- Joe S Hendricks

- Phone and address:

-

603 Greystone Blvd, Cabot, AR 72023

6018323346

Joseph Hendricks Phones & Addresses

- 603 Greystone Blvd, Cabot, AR 72023 • 6018323346

- Fayetteville, AR

Wikipedia References

Joseph Hendricks (Footballer)

Name / Title

Company / Classification

Phones & Addresses

SETON SQUARE WELLSTON, LLC

SETON SQUARE MARION, LLC

SETON SQUARE EAST, LLC

SETON SQUARE DOVER II, LLC

SETON SQUARE DOVER, LLC

SETON SQUARE ZANESVILLE, LLC

SETON LANCASTER, LLC

SETON KENTON, LLC

Us Patents

-

Systems And Methods For Replenishment In A Freight Tethering Environment

view source -

US Patent:20200372429, Nov 26, 2020

-

Filed:Jun 9, 2020

-

Appl. No.:16/896887

-

Inventors:- Bentonville AR, US

John L. Sokolsky - Rogers AR, US

Lara Shock - Bentonville AR, US

Jeremy Wales - Rogers AR, US

Joseph Hendricks - Bentonville AR, US

Terry Clear - Centerton AR, US

Marv Hansen - Bella Vista AR, US

Steve Ormon - Bentonville AR, US

Cliff Parks - Bella Vista AR, US -

International Classification:G06Q 10/06

G06Q 10/08 -

Abstract:Systems, methods, and machine readable medium are provided for replenishing product in a freight tethering environment. A pick list is generated at a hub store including one or more items that need to be replenished at a spoke store. It is determined whether the pick list can be fulfilled by the hub store. If the pick list cannot be fulfilled by the hub store, then the one or more items on the pick list is aggregated to a direct-store-delivery from the distribution center. The replenishment need of the spoke store is communicated to a distribution center. Product is received from the distribution center based on the replenishment need, and the pick list for the spoke store is fulfilled by the distribution center.

-

System And Method For Dynamic Perishable Item Replenishment

view source -

US Patent:20190287037, Sep 19, 2019

-

Filed:Mar 14, 2019

-

Appl. No.:16/353270

-

Inventors:- Bentonville AR, US

Leigh Ann Marie Scobey - Bentonville AR, US

Matthew D. Alexander - Rogers AR, US

Jeffrey Scott Cruz - Bentonville AR, US

Lacrecia Lynn Billings - Rogers AR, US

Joseph Wayne Hendricks - Bentonville AR, US -

International Classification:G06Q 10/06

G06Q 10/08

G06K 19/06

B65G 1/137 -

Abstract:System and methods for dynamic replenishment in a facility are disclosed. A mobile inventory processing device reads a machine readable tag affixed to a perishable item and transmits an indication of the perishable item to a stock inventory processing device. The stock inventory processing device retrieves a stock inventory value corresponding to the perishable item and a historic daily sales value for the perishable item from a database. The stock inventory processing device determines a restocking value based on whether the historic daily sales value exceeds the stock inventory value. The stock inventory processing device transmits a second indication to the mobile inventory processing device, The second indication correspond to insufficient shelf stock of the perishable item. The mobile inventory processing device receives the second indication and outputs an auditory alert in response to the second indication.

-

Systems And Methods For Replenishment In A Freight Tethering Environment

view source -

US Patent:20190266536, Aug 29, 2019

-

Filed:May 15, 2019

-

Appl. No.:16/413204

-

Inventors:- Bentonville AR, US

John L. Sokolsky - Rogers AR, US

Lara Shock - Bentonville AR, US

Jeremy Wales - Rogers AR, US

Joseph Wayne Hendricks - Bentonville AR, US

Terry Clear - Centerton AR, US

Marv Hansen - Bella Vista AR, US

Steve Ormon - Bentonville AR, US

Cliff Parks - Bella Vista AR, US -

International Classification:G06Q 10/06

G06Q 10/08 -

Abstract:Systems, methods, and machine readable medium are provided for replenishing product in a freight tethering environment. A pick list is generated at a hub store including one or more items that need to be replenished at a spoke store. It is determined whether the pick list can be fulfilled by the hub store. If the pick list cannot be fulfilled by the hub store, then the one or more items on the pick list is aggregated to a replenishment need of the hub store. The aggregated replenishment need of the hub store and the spoke store is communicated to a distribution center. Product is received from the distribution center based on the aggregated replenishment need, and the pick list for the spoke store is fulfilled from the received product.

-

Systems And Methods For Managing An Inventory Of Products Purchased By Customers From A Retailer

view source -

US Patent:20190172006, Jun 6, 2019

-

Filed:Feb 7, 2019

-

Appl. No.:16/270058

-

Inventors:- Bentonville AR, US

Courtland J. Halbrook - Centerton AR, US

Joseph W. Hendricks - Bella Vista AR, US -

International Classification:G06Q 10/08

G06Q 30/06 -

Abstract:In some embodiments, methods and systems are provided that permit a customer to purchase one or more products but not take possession of the products or cause delivery of the products at the time of the purchase order. The products are then stored at one or more product storage locations of the retailer while being marked as purchased by the customer in an inventory management database of the retailer. The customer is provided with a customer interface including a plurality of input fields configured to allow the customer to define one or both of: a delivery time period and a delivery destination for delivery of at least a portion of the products purchased by the customer; and a pickup location and a pickup time period for at least a portion of the products purchased by the customer.

-

Systems And Methods For Managing An Inventory Of Products Purchased By Customers From A Retailer

view source -

US Patent:20170270472, Sep 21, 2017

-

Filed:Mar 20, 2017

-

Appl. No.:15/463175

-

Inventors:- Bentonville AR, US

Courtland J. Halbrook - Centerton AR, US

Joseph W. Hendricks - Bella Vista AR, US -

International Classification:G06Q 10/08

G06Q 30/06 -

Abstract:In some embodiments, methods and systems are provided that permit a customer to purchase one or more products but not take possession of the products or cause delivery of the products at the time of the purchase order. The products are then stored at one or more product storage locations of the retailer while being marked as purchased by the customer in an inventory management database of the retailer. The customer is provided with a customer interface including a plurality of input fields configured to allow the customer to define one or both of: a delivery time period and a delivery destination for delivery of at least a portion of the products purchased by the customer; and a pickup location and a pickup time period for at least a portion of the products purchased by the customer.

-

Systems And Methods For Replenishment In A Freight Tethering Environment

view source -

US Patent:20160275428, Sep 22, 2016

-

Filed:Mar 14, 2016

-

Appl. No.:15/069501

-

Inventors:- Bentonville AR, US

John L. Sokolsky - Rogers AR, US

Lara Shock - Bentonville AR, US

Jeremy Wales - Rogers AR, US

Joseph Hendricks - Bella Vista AR, US

Terry Clear - Centerton AR, US

Marv Hansen - Bella Vista AR, US

Steve Ormon - Bentonville AR, US

Cliff Parks - Bella Vista AR, US -

International Classification:G06Q 10/06

G06Q 10/08 -

Abstract:Systems, methods, and machine readable medium are provided for replenishing product in a freight tethering environment. A pick list is generated at a hub store including one or more items that need to be replenished at a spoke store. It is determined whether the pick list can be fulfilled by the hub store. If the pick list cannot be fulfilled by the hub store, then the one or more items on the pick list is aggregated to a replenishment need of the hub store. The aggregated replenishment need of the hub store and the spoke store is communicated to a distribution center. Product is received from the distribution center based on the aggregated replenishment need, and the pick list for the spoke store is fulfilled from the received product.

Resumes

Joseph Hendricks

view source

Joseph Hendricks

view source

Joseph Hendricks

view sourceSkills:

Microsoft Office

Management

Microsoft Word

Sales Operations

Customer Satisfaction

Powerpoint

Microsoft Excel

New Business Development

Negotiation

Public Speaking

Customer Service

Management

Microsoft Word

Sales Operations

Customer Satisfaction

Powerpoint

Microsoft Excel

New Business Development

Negotiation

Public Speaking

Customer Service

Joseph Hendricks

view source

Joseph Hendricks

view source

Senior Sales Coordinator/Dispatcher At United Rentals

view sourceLocation:

United States

Joseph Hendricks

view source

Joseph Hendricks

view source

Joseph Schizo Hendricks

view source

Joseph P. Hendricks

view source

Joseph Keith Hendricks

view source

Joseph Hendricks

view source

Shelley Joseph Hendricks

view source

Joseph Hendricks

view sourceClassmates

Joseph Hendricks

view sourceSchools:

St. Agnes Cathedral School Rockville Centre NY 1956-1960

Community:

John Fideli, Kathleen Donnelly, Bobby Moran, Michael Niemczyk, Bob Edelman

Joseph Hendricks

view sourceSchools:

Ocean View High School Huntington Beach CA 1992-1996

Community:

Jonathan Couture, Susan Adams, Jennifer Venetianer, Roy Batelli

Joseph Hendricks

view sourceSchools:

Ballard-Hudson High School Macon GA 1978-1982

Community:

James Smith, Wilson Robinson, Brenda Hogan

Joseph Hendricks

view sourceSchools:

Peabody High School Pittsburgh PA 1974-1978

Community:

Leroy Mcnair, Bryan Keys, Jackie Mancini

Joseph Hendricks

view sourceSchools:

Largo High School Largo FL 1994-1998

Community:

Chris Allison, Richard Stephens

Joseph Griffin Hendricks

view sourceSchools:

Hughes-Kirk High School Beechmont KY 1940-1944

Community:

Roger Oglesby, Carl Davis, Kenneth Joines, Leo Shinn, Charles Bassett, W Wells, Ruby Dwyer

Joseph Hendricks | Lucern...

view source

Joseph Hendricks | Millar...

view sourceMyspace

Youtube

Googleplus

Joseph Hendricks

Joseph Hendricks

Joseph Hendricks

Joseph Hendricks

Joseph Hendricks

Joseph Hendricks

Joseph Hendricks

Flickr

Get Report for Joseph C Hendricks from Cabot, AR, age ~30