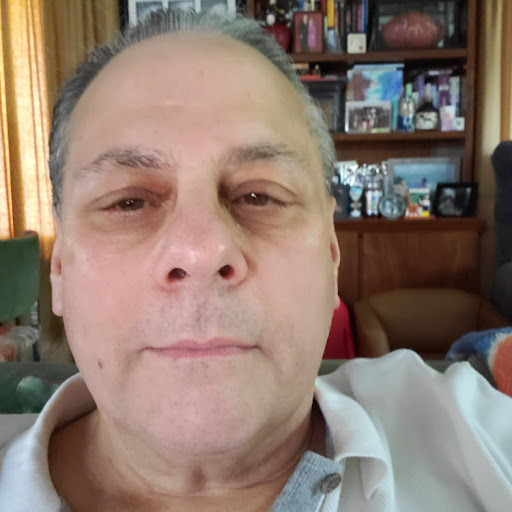

Louis G Simon

age ~65

from Miami Gardens, FL

- Also known as:

-

- Louis Georges Simon

- Louis Seth Simon

- Louis A Simon

- Louis Somon

- Simon S

- Phone and address:

- 2430 NW 185Th Ter APT 108, Miami, FL 33056

Louis Simon Phones & Addresses

- 2430 NW 185Th Ter APT 108, Miami Gardens, FL 33056

- 1461 118Th St, Miami, FL 33161 • 3058932945

- Hollywood, FL

- Basking Ridge, NJ

- Burbank, CA

Us Patents

-

Engineered Railroad Ties

view source -

US Patent:7011253, Mar 14, 2006

-

Filed:Nov 6, 2001

-

Appl. No.:09/985937

-

Inventors:Thomas Nosker - Stockton NJ, US

Richard Renfree - Scotch Plains NJ, US

James Kerstein - Watchung NJ, US

Louis Simon - Branchburg NJ, US -

Assignee:Polywood, Inc. - Edison NJ

-

International Classification:E01B 3/00

-

US Classification:238 30, 238 83

-

Abstract:To increase the resistance of plastic and/or plastic composite railroad ties tosliding within the ballast of the railroad bed, for example, sliding lengthwise (in the direction of the longitudinal axis of the tie) and sideways (in the direction perpendicular to the longitudinal axis), ties with a textured surface which aids in anchoring the ties within the ballast of the railroad beds. In particular, the ties are provided with a pattern of indentations within a surface that contacts the ballast which increases the ties resistance to sliding. The pattern is molded into the ties so as to mechanically interact with the ballast (rocks) and provide as much resistance to sliding as possible, especially along the longitudinal axis of the tie but also in the direction perpendicular to the longitudinal axis.

-

Use Of Recycled Plastics For Structural Building Forms

view source -

US Patent:7795329, Sep 14, 2010

-

Filed:Jul 21, 2003

-

Appl. No.:10/563883

-

Inventors:Thomas Nosker - Stockton NJ, US

Richard Renfree - Scotch Plains NJ, US

Maryann Renfree, legal representative - Scotch Plains NJ, US

James Kerstein - Watchung NJ, US

Louis Simon - Branchburg NJ, US -

Assignee:Rutgers, the State University of New Jersey - New Brunswick NJ

-

International Classification:C08K 9/02

-

US Classification:523204, 523500, 52518, 52578, 525861, 527821, 14 73, 14 771, 428101, 428119, 428384, 428908, 428 54, 238 29, 238 84, 238 57, 521 40, 521 405, 521 41

-

Abstract:Modular plastic structural composites having a web section disposed along a horizontal axis and at least one flange section disposed along a horizontal axis parallel thereto and integrally molded to engage the top or bottom surface of the web section, wherein said composite is formed from a mixture of (A) high density polyolefin and (B) a thermoplastic-coated fiber material, polystyrene, or a combination thereof. Composites molded in the form of I-Beams and bridges constructed therefrom are also disclosed.

-

Use Of Recycled Plastics For Structural Building Forms

view source -

US Patent:7996945, Aug 16, 2011

-

Filed:Aug 27, 2010

-

Appl. No.:12/870277

-

Inventors:Thomas Nosker - Stockton NJ, US

Richard Renfree - Scotch Plains NJ, US

Maryann Renfree, legal representative - Scotch Plains NJ, US

James Kerstein - Watchung NJ, US

Louis Simon - Branchburg NJ, US -

Assignee:Rutgers, The State University of New Jersey - New Brunswick NJ

-

International Classification:E01D 21/00

-

US Classification:14 771, 14 73, 14 731, 14 745, 14 75, 14 773, 523204, 523207, 522237, 524 23, 428 98, 428119, 2541711, 25417111, 25417117, 25417118, 254241

-

Abstract:Modular plastic structural composites having a web section disposed along a horizontal axis and at least one flange section disposed along a horizontal axis parallel thereto and integrally molded to engage the top or bottom surface of the web section, wherein said composite is formed from a mixture of (A) high density polyolefin and (B) a thermoplastic-coated fiber material, poly-styrene, or a combination thereof. Composites molded in the form of I-Beams and bridges constructed therefrom are also disclosed.

-

Use Of Recycled Plastics For Structural Building Forms

view source -

US Patent:8513360, Aug 20, 2013

-

Filed:Jul 8, 2011

-

Appl. No.:13/178798

-

Inventors:Thomas Nosker - Stockton NJ, US

James Kerstein - Watchung NJ, US

Louis Simon - Branchburg NJ, US

Maryann Renfree - Scotch Plains NJ, US -

Assignee:Rutgers, The State University of New Jersey - New Brunswick NJ

-

International Classification:C08J 3/00

-

US Classification:525197, 525191, 525240, 525242, 522237, 524751, 52578, 525861, 527821, 524 23, 524494, 14 73, 14 75, 14 771, 14 773, 523204, 26417111

-

Abstract:Modular plastic structural composites having a web section disposed along a horizontal axis and at least one flange section disposed along a horizontal axis parallel thereto and integrally molded to engage the top or bottom surface of the web section, wherein said composite is formed from a mixture of (A) high density polyolefin and (B) a thermoplastic-coated fiber material, poly-styrene, or a combination thereof. Composites molded in the form of I-Beams and bridges constructed therefrom are also disclosed.

-

Video Cassette Storage And Ejection Device

view source -

US Patent:42354900, Nov 25, 1980

-

Filed:Dec 26, 1978

-

Appl. No.:5/973154

-

Inventors:Gary M. Schwartz - East Windsor NJ

Louis Simon - Branchburg NJ -

Assignee:Le-Bo Products Company, Inc. - Maspeth NY

-

International Classification:A47B 8106

-

US Classification:312 15

-

Abstract:A container for storing and selectively presenting video tape cassettes of substantially equal thickness and depth and either a first or a second height includes a longitudinally extending box having longitudinally extending rear, bottom and top walls and transversely extending end walls defining a storage area having depth in excess of the depth of the cassettes. Partitions are provided which define storage locations, each of which has a longitudinal extent slightly in excess of the thickness of the cassettes, with the thickness and spacing of the partitions being such that when cassettes are placed into two adjacent storage locations, the space between them is insufficient to accommodate a human finger. Transversely extending ejection members, each mounted to the rear wall and projecting into one of the storage locations, each have a contact surface which is movable from a first position to a second position and is adapted to contact the rear panel of one of the cassettes when the cassette is inserted into the storage location with the rear panel at the first position. The ejection members are placed under sufficient compression when the contact surfaces are moved, by a cassette forcing them from the first to the second position, that when the cassette is subsequently released, the ejection member urges it a sufficient transverse distance such that at least a portion of the front of the cassette may be grasped by human fingers.

-

Combined Video Cassette Storage And Ejection Cabinet

view source -

US Patent:D2538601, Jan 8, 1980

-

Filed:Jan 3, 1978

-

Appl. No.:5/866603

-

Inventors:Gary M. Schwartz - East Windsor NJ

Louis Simon - Branchburg NJ -

Assignee:Le-Bo Products Company, Inc. - Maspeth NY

-

International Classification:D0604

-

US Classification:D 6130

Isbn (Books And Publications)

Dialogues Sur L'avenir: Chers Petits Qu'allez-Vous Devenir

view sourceAuthor

Louis Simon

ISBN #

2712100328

Resumes

Louis Simon

view source

Louis Simon

view sourceLocation:

United States

Name / Title

Company / Classification

Phones & Addresses

Ethics Administrator

Louisiana State Mineral Board

Information Retrieval Services

Information Retrieval Services

617 N 3Rd St Fl 8, Miami, FL 33155

President

Jrm Industries Inc

Commercial Printing

Commercial Printing

1 Mattimore St, Passaic Park, NJ 07055

Website: jrm.com

Website: jrm.com

President

JRM INDUSTRIES, INC

Narrow Fabric Mill Mfg Coat/Laminated Paper Mfg Converted Paper Prdt · Copies · Commercial Flexographic Printing

Narrow Fabric Mill Mfg Coat/Laminated Paper Mfg Converted Paper Prdt · Copies · Commercial Flexographic Printing

1 Mattimore St, Passaic, NJ 07055

9737799340, 9737798017, 8005332697

9737799340, 9737798017, 8005332697

Manager, Principal

Jasbi Developments, LLC

Subdivider/Developer

Subdivider/Developer

834 SW 159 Ln, Hollywood, FL 33027

Ethics Administrator

Louisiana State Mineral Board

617 N 3 St FL 8, Miami, FL 33155

3056666511

3056666511

Principal

Jrm Industries, Inc

Mfg Misc Products · Narrow Fabric Mill

Mfg Misc Products · Narrow Fabric Mill

1240 Goodrich Blvd, Los Angeles, CA 90022

3238380600

3238380600

President

JK&S CORPORATION INC

Treasurer, Secretary

Smith and Whitlock, Inc

4975 N University Dr, Fort Lauderdale, FL 33351

License Records

Louis D Simon

License #:

RS038166A - Expired

Category:

Real Estate Commission

Type:

Real Estate Salesperson-Standard

Vehicle Records

-

Louis Simon

view source -

Address:1461 NE 118 St, Miami, FL 33161

-

VIN:2G2WP552681145142

-

Make:PONTIAC

-

Model:GRAND PRIX

-

Year:2008

Lawyers & Attorneys

Louis Simon - Lawyer

view sourceOffice:

Jones Walker LLP

Specialties:

Admiralty and Maritime Law

Business and Commercial Litigation

Personal Injury

Business and Commercial Litigation

Personal Injury

ISLN:

903700410

Admitted:

1981

University:

Louisiana State University, B.A., 1977

Law School:

Paul M. Hebert Law Center, Louisiana State University, J.D., 1981

Myspace

Louis Simon

view sourceGoogleplus

Louis Simon

Work:

LPR

Louis Simon

Louis Simon

Louis Simon

Louis Simon

Louis Simon

Louis Simon

Louis Simon

Plaxo

Louis Simon

view sourceMalonne

Flickr

Louis A. Simon

view source

Louis Simon

view source

Louis Simon

view source

Louis Angelo Simon

view source

Louis Angelo Simon

view source

Louis Simon

view source

Louis Simon

view source

Louis Simon

view sourceClassmates

Louis Simon

view sourceSchools:

St. Patrick's High School Yellowknife Northwest Territories 1990-1994

Community:

Maryse Good, Freyja Gourlay, Erin Deacon, Barbara Arseneau

Louis Simon

view sourceSchools:

Melodyland High School Anaheim CA 1984-1986

Community:

Terry Thompson, Robynne Marchiano, Heidi Hamp, Elaine Maynard

Louis Simon

view sourceSchools:

St. Paul High School Niagara Falls Morocco 1996-2000

Louis Simon, Tolman High ...

view source

Simon Louis | Lewis and C...

view source

Lewis and Clark Middle Sc...

view sourceGraduates:

Simon Louis (1976-1980),

Cindy Carlson (1977-1978)

Cindy Carlson (1977-1978)

Wilson High School, Washi...

view sourceGraduates:

sharon howard (1974-1978),

Robert Longstrom (1969-1973),

Frank Hynson (1958-1962),

Renee Camacho (1984-1988),

Louis Simon (1955-1959)

Robert Longstrom (1969-1973),

Frank Hynson (1958-1962),

Renee Camacho (1984-1988),

Louis Simon (1955-1959)

Youtube

Get Report for Louis G Simon from Miami Gardens, FL, age ~65