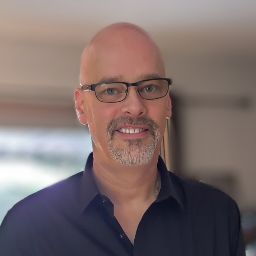

Mark S Borland

age ~61

from Troy, MI

- Also known as:

-

- Mark Stewart Borland

- Mark C Borland

- Mark Borland Stewart

- Phone and address:

-

5970 Slate Dr, Troy, MI 48007

2488287130

Mark Borland Phones & Addresses

- 5970 Slate Dr, Troy, MI 48007 • 2488287130

- Auburn Hills, MI

- Birmingham, MI

- Huntington Beach, CA

- Walnut, CA

- 5970 Slate Dr, Troy, MI 48085 • 3138287130

Work

-

Position:Professional/Technical

Education

-

Degree:High school graduate or higher

Us Patents

-

Control System For Lean Air-Fuel Ratio Nox Catalyst System

view source -

US Patent:6357226, Mar 19, 2002

-

Filed:Oct 22, 1998

-

Appl. No.:09/177314

-

Inventors:Mark Borland - Troy MI

-

Assignee:Chrysler Corporation - Auburn Hills MI

-

International Classification:F01H 300

-

US Classification:60298, 60286, 60295, 60300, 60303

-

Abstract:A control system is described for optimizing the reduction of nitrogen oxides in exhaust gas produced by an internal combustion engine, especially those internal combustion engines that employ a lean air-fuel ratio. The control system employs a temperature control assembly that is capable of selectively heating the exhaust gas prior to introduction into the NO catalyst system, thus rapidly bringing the temperature of the NO catalyst system up to operating temperature.

-

Fuel Scheduling As A Function Of Misfire Rate

view source -

US Patent:57352461, Apr 7, 1998

-

Filed:Sep 30, 1996

-

Appl. No.:8/723400

-

Inventors:Michael T. Vincent - Novi MI

Mark S. Borland - Birmingham MI

Kim A. Morehouse - Stockbridge MI

James R. Tamm - Ann Arbor MI -

Assignee:Chrysler Corporation - Auburn Hills MI

-

International Classification:F02D 4114

-

US Classification:123436

-

Abstract:A system is provided for controlling the ratio of fuel to air in an internal combustion engine to protect the catalyst substrate of a catalytic convertor from thermal damage. The system comprises detecting a misfire rate and adjusting the amount of fuel within the system accordingly. More particularly, the detected misfire rate is compared to at least one predetermined misfire rate within the engine control unit. If the detected misfire rate is not equal to the predetermined rate, the ratio of fuel to air is changed a calibrated amount. Accordingly, when the misfire rate exceeds a predetermined rate, additional fuel is added to the system. By increasing the ratio of fuel to air, the oxidation reaction is reduced and the exothermic activity within the catalytic converter is lowered.

-

Method For Processing Crankshaft Speed Fluctuations For Control Applications

view source -

US Patent:59016841, May 11, 1999

-

Filed:Sep 14, 1998

-

Appl. No.:9/152762

-

Inventors:John Fiaschetti - Rochester Hills MI

Kenneth DeGroot - Macomb Township MI

Mark Borland - Birmingham MI

Gregory Weber - Commerce Township MI -

Assignee:DaimlerChrysler Corporation - Auburn Hills MI

-

International Classification:F02D41/04

-

US Classification:123436

-

Abstract:A methodology of computing a learned combustion stability value and applying the learned combustion stability value to control engine operation is provided. Engine speed is sensed for each expected firing of individual cylinders ofthe engine. An expected acceleration value is determined using a band-pass-filtered engine speed difference. The difference between successive expected acceleration values is computed. A learned combustion related value is determined as a function of the difference in the successive learned acceleration values and is an indication of engine combustion quality. The operation of the engine is controlled as a function of the learned combustion related value. The learned combustion stability value is advantageously employed so as to modify the fuel injection to an internal combustion engine, especially following a cold engine start so as to reduce hydrocarbon emissions. This is accomplished by modifying a program target fuel injection value as a function of the learned combustion related value so as to reduce the fuel injected into the engine by fuel injectors.

-

Method Of Determining Start Of Closed-Loop Fuel Control For An Internal Combustion Engine

view source -

US Patent:55424031, Aug 6, 1996

-

Filed:Nov 18, 1994

-

Appl. No.:8/342297

-

Inventors:Mark S. Borland - Birmingham MI

Bruce H. Teague - Grosse Pointe Park MI -

Assignee:Chrysler Corporation - Highland Park MI

-

International Classification:F02D 4114

-

US Classification:123686

-

Abstract:A method of determining start of closed-loop fuel control for an internal combustion engine including the steps of determining a base fuel pulsewidth threshold, ascertaining whether a current accumulated base fuel pulsewidth is greater than or equal to the base fuel pulsewidth threshold, updating the current accumulated base fuel pulsewidth with a value of a previous accumulated base fuel pulsewidth plus the current base fuel pulsewidth if the current accumulated base fuel pulsewidth is not greater than or equal to the base fuel pulsewidth threshold, and beginning a closed loop fuel control of a plurality of fuel transferring components if the current accumulated base fuel pulsewidth is greater than or equal to the base fuel pulsewidth threshold.

-

Method For Processing Crankshaft Speed Fluctuations For Control Applications

view source -

US Patent:58099697, Sep 22, 1998

-

Filed:Jul 29, 1997

-

Appl. No.:8/901859

-

Inventors:John Fiaschetti - Warren MI

Kenneth P. DeGroot - Macomb Township MI

Mark S. Borland - Birmingham MI

Gregory T. Weber - Commerce Township MI -

Assignee:Chrysler Corporation - Auburn Hills MI

-

International Classification:F02D 4104

-

US Classification:123436

-

Abstract:A methodology of computing a learned combustion stability value and applying the learned combustion stability value to control engine operation is provided. Engine speed is sensed for each expected firing of individual cylinders of the engine. The difference in engine speed for a selected cylinder firing and a cylinder firing occurring two cylinder firings earlier is determined to provide an expected acceleration value. The difference between successive expected acceleration values is computed. A learned combustion related value is determined as a function of the difference in the successive learned acceleration values and is an indication of engine roughness. The operation of the engine is controlled as a function of the learned combustion related value. The learned combustion stability value is advantageously employed so as to modify the fuel injection to an internal combustion engine, especially following a cold engine start so as to reduce hydrocarbon emissions. This is accomplished by modifying a program target fuel injection value as a function of the learned combustion related value so as to reduce the fuel injected into the engine by fuel injectors.

-

Feedback Control Of Direct Injected Engines By Use Of A Smoke Sensor

view source -

US Patent:60558105, May 2, 2000

-

Filed:Aug 14, 1998

-

Appl. No.:9/134110

-

Inventors:Mark S. Borland - Troy MI

Thomas W. Asmus - Oakland MI

Frank Zhao - Lake Orion MI -

Assignee:Chrysler Corporation - Auburn Hills MI

-

International Classification:F02D 2300

F02M 2507

F02P 515 -

US Classification:60600

-

Abstract:A fuel control system for an engine utilizing direct fuel injection including a smoke sensor for measuring the level of smoke in the engine exhaust. A control module, in response to the output signal from the smoke sensor, regulates the timing and delivery of fuel to the engine, the delivery of air to the engine, the amount of exhaust gases that are recirculated to the engine, the turbo boost pressure and performs on-board diagnostics.

Name / Title

Company / Classification

Phones & Addresses

PITSTICK PAINTING, LLC

KROMOFORE, LLC

Resumes

Mark Borland

view source

Mark Borland

view source

Mark Borland

view sourceLicense Records

Mark D Borland

License #:

11336 - Expired

Category:

Health Care

Issued Date:

Aug 17, 2001

Effective Date:

Jun 16, 2003

Expiration Date:

May 31, 2003

Type:

Certified Respiratory Therapist

Googleplus

Mark Borland

Work:

Vue - Popcorn Scoopee (2010)

Education:

Queen Margaret University - Drama and Performance, Hamilton Grammar

Mark Borland

Mark Borland

Mark Borland

Mark Borland

Mark Borland

Mark Borland

Mark Borland

Youtube

Myspace

Flickr

Classmates

Mark Borland

view sourceSchools:

St. Pius X High School Albuquerque NM 1976-1980

Community:

Beth Hellwig, Charlie Burwinkle, John Cavanaugh, Danielle Scott

Broomfield High School, B...

view sourceGraduates:

Mark Borland (1989-1993),

Kristie King (1974-1978),

Kc Stringham (1998-2002),

Sandra Olsen (1981-1985),

Trudi Watkins (1966-1970),

Angela Benallo (1988-1992)

Kristie King (1974-1978),

Kc Stringham (1998-2002),

Sandra Olsen (1981-1985),

Trudi Watkins (1966-1970),

Angela Benallo (1988-1992)

St. Pius X High School, A...

view sourceGraduates:

Mark Borland (1976-1980),

Nancy Daut (1967-1971),

Louanne Lujan (1970-1974),

Julie Watts (1969-1973),

Michelle Mireles (1988-1992)

Nancy Daut (1967-1971),

Louanne Lujan (1970-1974),

Julie Watts (1969-1973),

Michelle Mireles (1988-1992)

Mark Borland

view source

Mark Borland

view source

Mark Borland

view source

Mark Borland

view source

Mark Borland

view source

Mark Borland

view source

Mark Borland

view source

Mark Borland

view sourceGet Report for Mark S Borland from Troy, MI, age ~61