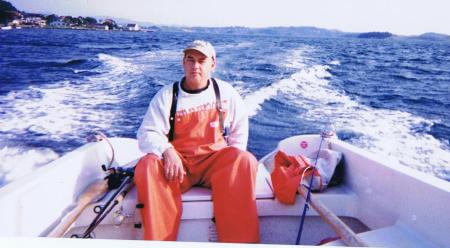

Mark L Marshall

age ~73

from Palm Springs, CA

- Also known as:

-

- Mark Linn Marshall

- Mark K Marshall

- Mark Marshal

- Phone and address:

-

1968 E Chia Rd, Palm Springs, CA 92262

9162124760

Mark Marshall Phones & Addresses

- 1968 E Chia Rd, Palm Springs, CA 92262 • 9162124760

- Los Ranchos, NM

- 619 17Th St, Sacramento, CA 95814 • 9164466061

- 616 17Th St, Sacramento, CA 95814

- Los Angeles, CA

- San Francisco, CA

- Riverside, CA

Medicine Doctors

Dr. Mark A Marshall, Carmichael CA - DO (Doctor of Osteopathic Medicine)

view sourceSpecialties:

Emergency Medicine

Age:

42

Address:

6501 Coyle Ave, Carmichael, CA 95608

9168645550 (Phone)

2500 Metrohealth Dr, Cleveland, OH 44109

2167787800 (Phone), 2167788226 (Fax)

EMERGENCY MEDICAL PRACTITIONERS

3300 Douglas Blvd Suite 405, Roseville, CA 95661

8473379051 (Phone)

CALIFORNIA EMERGENCY PHYSICIAN

2100 Powell St Suite 920, Emeryville, CA 94608

5103502777 (Phone), 5108799100 (Fax)

9168645550 (Phone)

2500 Metrohealth Dr, Cleveland, OH 44109

2167787800 (Phone), 2167788226 (Fax)

EMERGENCY MEDICAL PRACTITIONERS

3300 Douglas Blvd Suite 405, Roseville, CA 95661

8473379051 (Phone)

CALIFORNIA EMERGENCY PHYSICIAN

2100 Powell St Suite 920, Emeryville, CA 94608

5103502777 (Phone), 5108799100 (Fax)

Languages:

English

Mark S. Marshall

view sourceSpecialties:

Psychiatry

Work:

Mental Health Center Of Denver

4455 E 12 Ave, Denver, CO 80220

3035041800 (phone), 3035128858 (fax)

4455 E 12 Ave, Denver, CO 80220

3035041800 (phone), 3035128858 (fax)

Education:

Medical School

University of Illinois, Chicago College of Medicine

Graduated: 1985

University of Illinois, Chicago College of Medicine

Graduated: 1985

Procedures:

Psychiatric Therapeutic Procedures

Conditions:

Schizophrenia

Anxiety Dissociative and Somatoform Disorders

Anxiety Phobic Disorders

Attention Deficit Disorder (ADD)

Bipolar Disorder

Anxiety Dissociative and Somatoform Disorders

Anxiety Phobic Disorders

Attention Deficit Disorder (ADD)

Bipolar Disorder

Languages:

English

Spanish

Spanish

Description:

Dr. Marshall graduated from the University of Illinois, Chicago College of Medicine in 1985. He works in Denver, CO and specializes in Psychiatry.

Mark D. Marshall

view sourceSpecialties:

Emergency Medicine

Work:

Mille Lacs Health System

200 Elm St N STE A, Onamia, MN 56359

3205323154 (phone), 3205322359 (fax)

200 Elm St N STE A, Onamia, MN 56359

3205323154 (phone), 3205322359 (fax)

Languages:

English

Description:

Mr. Marshall works in Onamia, MN and specializes in Emergency Medicine. Mr. Marshall is affiliated with Mille Lacs Health System.

Isbn (Books And Publications)

Us Patents

-

Quick Setting And Release Actuator For Work Holder

view source -

US Patent:59346884, Aug 10, 1999

-

Filed:Apr 27, 1998

-

Appl. No.:9/066591

-

Inventors:Jerald W. VanderPol - Shingle Springs CA

Mark A. Marshall - Sacramento CA

Donald T. Stanley - Lincoln CA

Clement Tremblay - Citrus Heights CA -

Assignee:Tri Tool Inc. - Rancho Cordova CA

-

International Classification:B23B 3120

B23B 516 -

US Classification:279 58

-

Abstract:A quick setting and release actuator for cooperating with an axially movable chuck for holding a tubular workpiece in fixed position includes an anchor member (12) that is mounted in fixed relationship relative to a housing of a machine tool (20) and a thrust member (42) carried by a pivotally mounted carrier member (38) that pivots towards and away from the anchor member to drive the thrust member (42) into engagement with the end wall (44) of a multi-segment collet (26) to cause the collet to ride along its segment bearing surfaces (30) in a radial direction to engage the periphery of a workpiece (24) to be retained in the machine tool (20). Thrust member (42) may be pivotally mounted by a pivot connection (48) on the carrier (38) so that the thrust member will align itself with the end wall (44) of collet (26) even when the carrier is not precisely parallel with the collet end wall. In an alternative arrangement, rounded thrust pins may be used to transmit axial force to the collet (26) and this arrangement may include a thrust transmitting spacer (86). A lever (50) and cam (52) arrangement is provided to exert positive force on the carrier (38) at its terminal pivoted position by means of a thrust rod (54) cooperating with a thrust nut (58) connected to the thrust rod.

-

Pipe End Preparation Tool Having Improved Torque Reacting And Clamping Capabilities

view source -

US Patent:50834843, Jan 28, 1992

-

Filed:Jul 5, 1990

-

Appl. No.:7/548663

-

Inventors:Jerald VanderPol - Eldorado Hills CA

Mark A. Marshall - Sacramento CA

Warren V. Wheeler - Placerville CA -

Assignee:Tri Tool Inc. - Rancho Cordova CA

-

International Classification:8 2

8 2

B23B 322 -

US Classification:82113

-

Abstract:The present invention relates to a clamping device for clamping a mandrel to an elbow or pipe as well as to a torque-reacting device between a power unit housing and the mandrel. The torque reacting device has a pair of torque reacting keys mounted in a non-rotatable portion of the power unit housing, each of the keys having an end portion with converging opposite sides. The end portions of the torque reacting keys extend into correspondingly shaped, axially extending grooves formed in opposite sides of the mandrel. The opposite sides of the grooves are outwardly diverging and define an included angle approximately equal to the angle between the converging sides of the torque reacting keys. Adjusting screws are provided for each of the torque reacting keys. The clamping device has a plurality of clamping pins, each pin having a generally cylindrical shape with a hemispherical end portion defining a plurality of concentric ridges.

-

Tube Squaring Tool

view source -

US Patent:59411457, Aug 24, 1999

-

Filed:Nov 14, 1997

-

Appl. No.:8/970198

-

Inventors:Mark A. Marshall - El Dorado Hills CA

Marty E. Pound - Elk Grove CA -

Assignee:TRI Tool Inc. - Rancho Cordova CA

-

International Classification:B23B 508

-

US Classification:82113

-

Abstract:A tube squaring tool includes a housing having forward and rearward end areas and a tubular workpiece clamping device located at the forward end area for securing and retaining a tubular workpiece relative to the housing so that the end of the workpiece can be machined by a rotary cutting head carried by the housing and movable towards and away from the end of the workpiece by manipulation of a feed mechanism. The tubular workpiece clamping device includes a pair of saddle members carried within a saddle mounting ring with one of the saddle members being frictionally secured within the mounting ring using a detent mechanism and the other saddle member being movable relative to the mounting ring and the opposing saddle member by a threaded connector that enables clamping of a tubular workpiece between the saddle members when the moveable saddle member is moved in a clamping direction towards the opposed fixed saddle member. Interchangeability of the saddle members to accommodate different size workpieces is facilitated by the friction coupling between one of the saddle members and the mounting ring and the saddle members are configured so that they may be readily removed and replaced through a radial retaining projection located on the forward end of the mounting ring.

-

Pipe End Preparation Tool Having Improved Torque Reacting And Clamping Capabilities

view source -

US Patent:49552635, Sep 11, 1990

-

Filed:Jun 30, 1989

-

Appl. No.:7/373517

-

Inventors:Jerald VanderPol - Eldorado Hills CA

Mark A. Marshall - Sacramento CA

Warren V. Wheeler - Placerville CA -

Assignee:Tri Tool Inc. - Rancho Cordova CA

-

International Classification:B23B 300

B23B 700 -

US Classification:82118

-

Abstract:The present invention relates to a clamping device for clamping a mandrel to an elbow or pipe as well as to a torque-reacting device between a power unit housing and the mandrel. The torque reacting device has a pair of torque reacting keys mounted in a non-rotatable portion of the power unit housing, each of the keys having an end portion with converging opposite sides. The end portions of the torque reacting keys extend into correspondingly shaped, axially extending grooves formed in opposite sides of the mandrel. The opposite sides of the grooves are outwardly diverging and define an included angle approximately equal to the angle between the converging sides of the torque reacting keys. Adjusting screws are provided for each of the torque reacting keys. The clamping device has a plurality of clamping pins, each pin having a generally cylindrical shape with a hemispherical end portion defining a plurality of concentric ridges.

-

Quick Setting And Release Actuator For Work Holder

view source -

US Patent:57435391, Apr 28, 1998

-

Filed:Jun 10, 1996

-

Appl. No.:8/660884

-

Inventors:Jerald W. VanderPol - Shingle Springs CA

Mark A. Marshall - Sacramento CA

Donald T. Stanley - Lincoln CA

Clement Tremblay - Citrus Heights CA -

Assignee:Tri Tool Inc. - Rancho Cordova CA

-

International Classification:B23B 3120

B23B 516 -

US Classification:279 58

-

Abstract:A quick setting and release actuator for cooperating with an axially movable chuck for holding a tubular workpiece in fixed position includes an anchor member (12) that is mounted in fixed relationship relative to a housing of a machine tool (20) and a thrust member (42) carried by a pivotally mounted carrier member (38) that pivots towards and away from the anchor member to drive the thrust member (42) into engagement with the end wall (44) of a multi-segment collet (26) to cause the collet to ride along its segment bearing surfaces (30) in a radial direction to engage the periphery of a workpiece (24) to be retained in the machine tool (20). Thrust member (42) may be pivotally mounted by a pivot connection (48) on the carrier (38) so that the thrust member will align itself with the end wall (44) of collet (26) even when the carrier is not precisely parallel with the collet end wall. In an alternative arrangement, rounded thrust pins may be used to transmit axial force to the collet (26) and this arrangement may include a thrust transmitting spacer (86). A lever (50) and cam (52) arrangement is provided to exert positive force on the carrier (38) at its terminal pivoted position by means of a thrust rod (54) cooperating with a thrust nut (58) connected to the thrust rod.

-

Tube Squaring Tool

view source -

US Patent:D477245, Apr 6, 1999

-

Filed:Nov 14, 1997

-

Appl. No.:D/079211

-

Inventors:Mark A. Marshall - El Dorado Hills CA

Marty E. Pound - Elk Grove CA -

Assignee:Tri Tool Inc. - Rancho Cordova CA

-

International Classification:1509

-

US Classification:D15130

Name / Title

Company / Classification

Phones & Addresses

Truclean

Carpet & Rug Cleaners

Carpet & Rug Cleaners

200 Lake Blvd, # 424, Buffalo Grove, IL 60089-4388

8478496500

8478496500

Partner

Collins Barrow Nova Scotia Inc.

Accountants. Bookkeeping Service. Accountants - Certified Public

Accountants. Bookkeeping Service. Accountants - Certified Public

120 Eileen Stubbs Ave., Suite 101, Dartmouth, NS B3B 1Y1

9024044000, 9024043099

9024044000, 9024043099

Partner

Collins Barrow Nova Scotia Inc

Accountants · Bookkeeping Service · Accountants - Certified Public

Accountants · Bookkeeping Service · Accountants - Certified Public

9024044000, 9024043099

M.I.S.T., LLC

OHIO SPECIAL RESPONSE TEAM, INC

MATT MARSHALL CONSTRUCTION COMPANY

CRJ SEARCH LLC

COLUMBUS COMMERCE SOLUTIONS, LLC

License Records

Mark A Marshall

License #:

3515 - Active

Issued Date:

Oct 4, 2010

Expiration Date:

Sep 28, 2018

Type:

Sheet Metal Master

Mark A Marshall

License #:

15318 - Active

Issued Date:

Oct 11, 2007

Expiration Date:

May 1, 2018

Type:

Master Plumber

Mark Alan Marshall

License #:

66882 - Expired

Category:

Nursing

Issued Date:

Jan 23, 2008

Effective Date:

Jul 13, 2010

Expiration Date:

Oct 31, 2010

Type:

Registered Nurse

Mark A Marshall

License #:

RS073437A - Expired

Category:

Real Estate Commission

Type:

Real Estate Salesperson-Standard

Lawyers & Attorneys

Mark Marshall - Lawyer

view sourceSpecialties:

Chapter 7 Bankruptcy

Criminal Defense

Child Support

Criminal Defense

Child Support

ISLN:

911377918

Admitted:

1991

Googleplus

Mark Marshall

Work:

JCrew - Associate Manager - Training (6)

JCrew - Store Director (7-6)

JCrew - Store Director (7-6)

Education:

Saint Anselm College - Theology

Tagline:

When in doubt... nap

Mark Marshall

Work:

Albert Heijn - Teamleider (2004)

Education:

Fontys Hogescholen - Financial Services Management, Gilde Opleidingen - Bank- en Verzekeringswezen

Tagline:

Student Financial Services Management

Mark Marshall

Education:

University of Edinburgh - Mathematics, Grangemouth High School

Tagline:

Hi, I'm Mark

Mark Marshall

Work:

Disabled 17yrs

Mark Marshall

Work:

Car Fix Center - Auto Repair Shop

Mark Marshall

Work:

Toyota - Tm

Mark Marshall

Tagline:

IT Coach and International Teacher

Mark Marshall

Tagline:

Married to most amazing women in the world and have two fabulous boys.

Flickr

Youtube

Myspace

Plaxo

mark marshall

view sourceDr at Mark Marshall DDS Inc.

mark marshall

view sourcevice pres at Marshall Precision Machining

Mark Marshall

view sourceBusiness Development Manager at eDirect Impact

Mark Marshall

view sourceBerkhamsted UKService Monitor Group

Mark Marshall

view sourceBentz Whaley Flessner

Mark Marshall Jr.

view source

Nathan Mark Marshall Sopha

view source

Mark Marshall

view source

Mark W. Marshall Sr.

view source

Mark Marshall

view source

Mark Anthony Marshall

view source

Mark William Marshall

view source

Sim Mark Marshall

view sourceClassmates

Mark (Marshall) Horner

view sourceSchools:

Sacred Heart School Warner Robins GA 1966-1973, Mt. De Sales Academy Macon GA 1973-1977

Community:

Gerry Schulze, Zackulyn Baybay

Biography:

Life

I have two wonderful children; one finishing college in Texas and the other liv...

Mark Mars (Marshall)

view sourceSchools:

Hershey High School Hershey PA 1991-1995

Mark Marshall

view sourceSchools:

Monteith Elementary School Grosse Pointe MI 1966-1970, Brownell Middle School Grosse Pointe MI 1970-1972

Community:

Rosemary Borden

Mark Marshall

view sourceSchools:

Delaware Valley High School Philadelphia PA 1979-1983

Community:

William Mangum, Mike Glickstein, John Kuczynski

Mark Marshall

view sourceSchools:

Reitz Memorial High School Evansville IN 1980-1984

Community:

Jill Martin, Roberta Fisher, Rick Notter, Lynne Gerleman

Mark Marshall

view sourceSchools:

Senator Riley High School High River Azores 1975-1979

Community:

Tara Gostola, Vanessa Black, Jill Lemieux, Jessica Rowland

Mark Marshall

view sourceSchools:

Bangor Adult Education Bangor ME 1983-1987

Mark Marshall

view sourceSchools:

Upper Dauphin High School Elizabethville PA 1986-1989

Community:

Laurie Christy, Michelle Lytle, Joselyn Pieri

Get Report for Mark L Marshall from Palm Springs, CA, age ~73