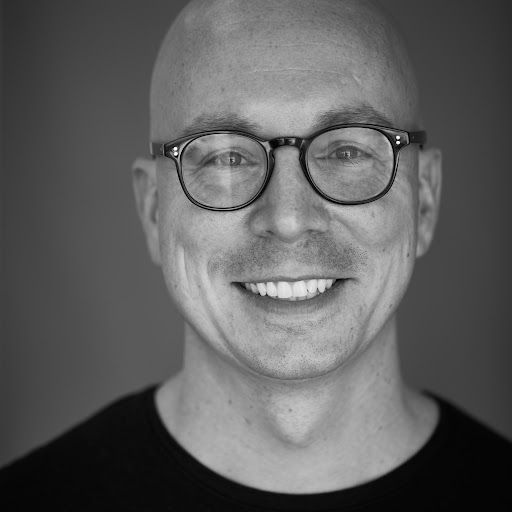

Michael G Garvey

age ~70

from San Jose, CA

- Also known as:

-

- Michael G Gravey

Michael Garvey Phones & Addresses

- San Jose, CA

- Wellington, FL

- Lithonia, GA

- Hollywood, FL

- Coral Springs, FL

- Palm Beach, FL

Lawyers & Attorneys

Michael B Garvey, Palo Alto CA - Lawyer

view sourceAddress:

650 Page Mill Rd, Palo Alto, CA 94304

6508493364 (Office)

6508493364 (Office)

Licenses:

California - Active 2011

Education:

Boston Coll Law School

Boston College

Boston College

Specialties:

Business - 100%

Michael Garvey - Lawyer

view sourceSpecialties:

Administrative Hearings and Appeals

Municipal Planning and Development

Property Tax Assessment Appeals

Zoning, Planning and Land Use

Municipal Planning and Development

Property Tax Assessment Appeals

Zoning, Planning and Land Use

ISLN:

907180935

Admitted:

1990

University:

University of Western Ontario, B.A., 1985

Law School:

Queens University, LL.B., 1988

Michael Garvey - Lawyer

view sourceSpecialties:

Traffic Violations

Criminal Law

Personal Injury

Criminal Defense

Criminal Law

Personal Injury

Criminal Defense

ISLN:

900953062

Admitted:

1978

University:

DePaul University, B.A., 1988

Law School:

University of Illinois, J.D., 1991

Michael Garvey - Lawyer

view sourceOffice:

Pearne & Gordon LLP

Specialties:

Patents

Trademarks

Prosecution and Appeals

Intellectual Property

Patent Application

Licensing

Litigation

Trademarks

Prosecution and Appeals

Intellectual Property

Patent Application

Licensing

Litigation

ISLN:

901781510

Admitted:

1991

University:

University of Notre Dame, B.S.E.E., 1984

Law School:

College of William and Mary, J.D., 1991

Michael Garvey - Lawyer

view sourceOffice:

Wilson Sonsini Goodrich & Rosati Professional Corporation

Specialties:

Corporate Finance

Corporate Law & Governance

Entrepreneurial Services

Mergers & Acquisitions

Venture Capital

Business Law

Intellectual Property Law

Corporate Law & Governance

Entrepreneurial Services

Mergers & Acquisitions

Venture Capital

Business Law

Intellectual Property Law

ISLN:

922337741

Admitted:

2011

University:

Boston College, B.A., 2006; Boston College, B.A., 2006

Law School:

Boston College Law School, J.D., 2010

Isbn (Books And Publications)

The Veterinarians' Guide to Your Dog's Symptoms: Your Pet Can't Speak, but Its Symptoms Can

view sourceAuthor

Michael S. Garvey

ISBN #

0375752269

The Veterinarians' Guide to Your Cat's Symptoms

view sourceAuthor

Michael S. Garvey

ISBN #

0375752277

The Veterinarians' Guide to Your Dog's Symptoms: Your Pet Can't Speak, but Its Symptoms Can

view sourceAuthor

Michael Garvey

ISBN #

0375752269

Wikipedia References

Michael Garvey

Michael Garvey (Rugby League)

Us Patents

-

Hybrid Absorbent Foam And Articles Containing It

view source -

US Patent:8158689, Apr 17, 2012

-

Filed:Dec 22, 2005

-

Appl. No.:11/315576

-

Inventors:Andrew T. Baker - Norcross GA, US

Timothy James Blenke - Neenah WI, US

Charles W. Colman - Marietta GA, US

Edward A. Colombo - Penfield NY, US

Jeffrey E. Fish - Dacula GA, US

Kaiyuan Yang - Cumming GA, US

Michael Joseph Garvey - Appleton WI, US

Jeffrey Jennings Krueger - Marietta GA, US

Mary Frances Mallory - Alpharetta GA, US

Joseph E. Pierce - Appleton WI, US

Fred Robert Radwanski - Stone Mountain GA, US

Sridhar Ranganathan - Suwanee GA, US

Donald E. Waldroup - Roswell GA, US -

Assignee:Kimberly-Clark Worldwide, Inc. - Neenah WI

-

International Classification:C08J 9/00

B32B 3/26 -

US Classification:521 50, 428159

-

Abstract:A hybrid absorbent foam includes an integrated hybrid foam layer having an open surface, a closed surface, and a foam body extending between the open and closed surfaces. The integrated hybrid foam layer has an open-cell content of at least 50%, while the closed surface provides a barrier to aqueous liquids. The integrated hybrid foam layer is formed as a single layer, and has a substantially uniform polymer composition throughout its thickness. The integrated hybrid foam layer combines the functions of liquid absorbency, retention, and barrier into a single layer, and is useful in a wide variety of absorbent articles.

-

Absorbent Article With Stabilized Absorbent Structure

view source -

US Patent:20030119405, Jun 26, 2003

-

Filed:Nov 27, 2002

-

Appl. No.:10/306201

-

Inventors:Frank Abuto - Duluth GA, US

Mark Beitz - Appleton WI, US

Jayant Chakravarty - Appleton WI, US

Michael Garvey - Appleton WI, US

Timothy Rymer - Appleton WI, US

Michael Venturino - Appleton WI, US

Robert Vogt - Neenah WI, US -

Assignee:Kimberly-Clark Worldwide, Inc.

-

International Classification:D04H001/00

D04H003/00

D04H005/00

D04H013/00

B32B005/26 -

US Classification:442/361000, 442/381000, 442/414000

-

Abstract:An absorbent article having a liner and an outer cover in generally opposed relationship with the liner. An absorbent body disposed therebetween includes a non-woven absorbent structure having a length, a width and a thickness. The absorbent structure is constructed of absorbent fibers and binder fibers activatable to form inter-fiber bonds within the absorbent structure, with the binder fibers being multi-component fibers in which at least one binder fiber component has a melt temperature that is lower than a melt temperature of at least one other binder fiber component. The width of the absorbent structure is non-uniform along its length prior to activation of the binder fibers. In another embodiment, the absorbent structure is of unitary construction and the concentration of binder fibers therein is non-uniform along at least one of the length, the width and the thickness of the absorbent structure.

-

Targeted On-Line Stabilized Absorbent Structures

view source -

US Patent:20030119406, Jun 26, 2003

-

Filed:Dec 20, 2001

-

Appl. No.:10/033860

-

Inventors:Francis Abuto - Duluth GA, US

Mark Beitz - Appleton WI, US

Jayant Chakravarty - Appleton WI, US

Jenny Day - Woodstock GA, US

Michael Garvey - Appleton WI, US

Timothy Rymer - Appleton WI, US

David Stagray - Neenah WI, US

Michael Venturino - Appleton WI, US

Jerome Workman - Appleton WI, US -

International Classification:D04H001/00

D04H003/00

D04H005/00

D04H013/00 -

US Classification:442/364000, 442/361000

-

Abstract:A nonwoven structure or web is provided where a binder fiber contains an energy receptive additive. The fiber provides rapid heating when subjected to dielectric energy such as radio frequency or microwave radiation. The energy receptive additive has a dielectric loss of at between 0.5, preferably 0.1 and most preferably 5, and 15.

License Records

Michael C Garvey

License #:

116002 - Expired

Issued Date:

Apr 17, 1989

Expiration Date:

Mar 16, 2000

Type:

Salesperson

Michael Robert Garvey

License #:

Unknown - Expired

Category:

Nursing

Effective Date:

Feb 24, 2017

Type:

Registered Nurse

Michael Garvey

License #:

009032 - Expired

Category:

HOIST MACHINE OPERATOR

Issued Date:

Jun 1, 1998

Expiration Date:

May 31, 2015

Michael Garvey

Address:

PO Box 212877, West Palm Beach, FL 33421

License #:

SL3017396 - Active

Category:

Real Estate

Issued Date:

Dec 27, 2001

Effective Date:

Mar 19, 2015

Expiration Date:

Sep 30, 2017

Type:

Sales Associate

Name / Title

Company / Classification

Phones & Addresses

President

Garvey & Associates, Inc.

Garvey & Assoc. Employee Benefit Solutions

Insurance Companies. Insurance Services - Commercial. Retirement Planning Service. Pension & Profit Sharing Plans. Insurance Consultants. Insurance Claim Processing Services. Insurance - Health. Hospitalization. Medical & Surgical Plans

Garvey & Assoc. Employee Benefit Solutions

Insurance Companies. Insurance Services - Commercial. Retirement Planning Service. Pension & Profit Sharing Plans. Insurance Consultants. Insurance Claim Processing Services. Insurance - Health. Hospitalization. Medical & Surgical Plans

12110 Port Grace Blvd # 201, Southport Professional Building, La Vista, NE 68128-3190

4023989456

4023989456

President

Michael J Garvey Inc

Amusement/Recreation Services

Amusement/Recreation Services

1010 SW 110 Ter, Fort Lauderdale, FL 33324

9543708909

9543708909

Secretary, Vice President

M'S 7 CHILDREN, INC

1327 S Dixie Hwy, Pompano Beach, FL 33060

10291 Waterside Ct, Pompano Beach, FL 33076

10291 Waterside Ct, Pompano Beach, FL 33076

GARVEY INVESTMENTS LLC

ARCHON TOOL AND DIE, LLC

M & J DEVELOPMENT, LTD

DGTZ PARTNERS, LLC

MIDWEST COMMERCIAL REAL ESTATE, LLC

Medicine Doctors

Michael A. Garvey

view sourceSpecialties:

Nephrology

Work:

Southern Manhattan Dialysis

510 Ave Of The Americas Frnt 3, New York, NY 10011

2126756880 (phone), 2127270821 (fax)

510 Ave Of The Americas Frnt 3, New York, NY 10011

2126756880 (phone), 2127270821 (fax)

Education:

Medical School

New York Medical College

Graduated: 1975

New York Medical College

Graduated: 1975

Procedures:

Dialysis Procedures

Conditions:

Acute Bronchitis

Acute Renal Failure

Acute Sinusitis

Chronic Renal Disease

Diabetes Mellitus (DM)

Acute Renal Failure

Acute Sinusitis

Chronic Renal Disease

Diabetes Mellitus (DM)

Languages:

Chinese

English

Spanish

English

Spanish

Description:

Dr. Garvey graduated from the New York Medical College in 1975. He works in New York, NY and specializes in Nephrology. Dr. Garvey is affiliated with Mount Sinai Beth Israel Brooklyn Medical Center.

Plaxo

MICHAEL GARVEY

view source

Michael Garvey

view source

Michael Garvey

view sourcePresident at Garvey Consulting Services

michael garvey

view sourceMarriott

Michael Garvey

view sourceMonticello, AR

Michael Garvey

view sourceHamilton County Clerk of Courts

Michael Garvey

view sourcebaker mckenzie

Classmates

Michael Garvey

view sourceSchools:

Abbotsford Junior High School Abbotsford Saudi Arabia 1976-1979

Community:

John Tyrrell, Debbie Hildebrand, Leanne Fox

Michael Garvey

view sourceSchools:

Orchard View High School Muskegon MI 1997-2001

Community:

Morley Curtis, Debra Hewitt

Michael Garvey

view sourceSchools:

Kennedy High School Warren OH 1975-1979

Community:

Raymond Hays, Brian Gustovich, James Durkin, Jerilynn Case

Michael Garvey

view sourceSchools:

St. Albert the Great School Huntingdon Valley PA 1967-1971

Community:

William Hassiepen, Eric Mentzel

Michael Garvey

view sourceSchools:

St. Catherine of Genoa School Chicago IL 1955-1964

Community:

Sandra Hubl, Yvetta Williams, Janice Koch

Michael Garvey

view sourceSchools:

Harriet Beecher Stowe School Scranton PA 1975-1979

Community:

Annie Glucksnis, Paula Bochak

Michael Garvey

view sourceSchools:

St. Mary's Academy Alexandria VA 1977-1981, Bishop Ireton High School Alexandria VA 1977-1981

Community:

Jeff Mcgrath, Christine Wells, Fred Hopewell, Denise Jardin, John Trippel

Michael Garvey

view sourceSchools:

Holy Name of Jesus High School Chicopee MA 1983-1987

Community:

Christopher Gatcomb, Tom Fitch, Joyce Douville

Michael O. Garvey

view source

Michael Garvey

view source

Michael Garvey

view source

Michael Paul Garvey

view source

Michael Garvey

view source

Michael Garvey

view source

Michael Garvey

view source

Michael Garvey

view sourceGoogleplus

Michael Garvey

Work:

Charlotte Eye, Ear, Nose, and Throat - Tech Support Analyst (2006)

Education:

Charlotte Country Day School

Michael Garvey

Work:

Freelance Designer

Education:

University of Portland - Organizational Communication

Michael Garvey

Work:

EN Engineering, LLC - Vice President Business Development

Education:

Purdue University - BSME

Michael Garvey

Work:

TGM Inc. - Boss (2011)

TGM Inc. - Minion (2007-2010)

TGM Inc. - Minion (2007-2010)

Michael Garvey

Michael Garvey

Michael Garvey

Michael Garvey

Youtube

Myspace

Michael Garvey

view source

Michael Garvey

view sourceLocality:

Rockhampton isn't a city...., Queensland

Gender:

Male

Birthday:

1941

Flickr

Get Report for Michael G Garvey from San Jose, CA, age ~70