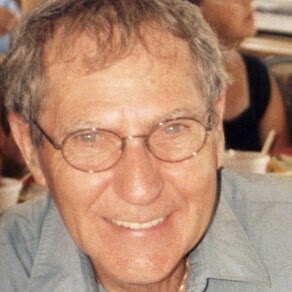

Patrick L Draper

age ~62

from Smithfield, UT

- Also known as:

-

- Patrick Larry Draper

- Pat L Draper

- Phone and address:

-

340 E 200 N, Smithfield, UT 84335

4355633161

Patrick Draper Phones & Addresses

- 340 E 200 N, Smithfield, UT 84335 • 4355633161

- Logan, UT

Work

-

Position:Protective Service Occupations

Education

-

Degree:High school graduate or higher

Resumes

Patrick Draper

view source

Patrick Draper

view sourceUs Patents

-

Methods And Apparatus For Mixing And Shipping Fluids

view source -

US Patent:20120175012, Jul 12, 2012

-

Filed:Jan 7, 2011

-

Appl. No.:12/986701

-

Inventors:Michael E. Goodwin - Logan UT, US

Jacob D. Lee - Smithfield UT, US

Whitt F. Woods - North Ogden UT, US

Patrick L. Draper - Smithfield UT, US -

Assignee:HYCLONE LABORATORIES, INC. - Logan UT

-

International Classification:B65B 3/04

B65D 25/14

B01F 13/00 -

US Classification:141 11, 366200, 22049501

-

Abstract:A method for mixing includes releasably coupling a first container station to a docking station, the first container station having a shipping vessel bounding a compartment, the docking station having a stand and a drive motor assembly adjustably mounted to the stand. The vertical or horizontal position of the drive motor assembly is adjusted relative to the stand so that the drive motor assembly is in a first position. A drive shaft is advanced through the drive motor assembly and into a chamber of a first collapsible bag disposed within the compartment of the shipping vessel. The drive motor assembly is activated so that the mixer rotates the drive shaft causing mixing of the fluid within the first collapsible bag.

-

Methods And Apparatus For Processing Fluids

view source -

US Patent:20200324257, Oct 15, 2020

-

Filed:Dec 16, 2019

-

Appl. No.:16/715137

-

Inventors:- Carlsbad CA, US

Jacob D. Lee - Smithfield UT, US

Whitt F. Woods - North Ogden UT, US

Patrick L. Draper - Smithfield UT, US -

International Classification:B01F 7/16

B01F 3/04

B01F 7/00

B01F 7/22

B01F 13/00

B01F 15/00

C12M 1/00

C12M 1/06

B65B 1/02 -

Abstract:A method for processing a fluid includes removably securing a retention member to a vessel that bounds a chamber; inserting a collapsible bag within the chamber of the vessel; securing the bag to the retention member so that the bag is supported within the chamber of the vessel; and dispensing a fluid into a compartment of the collapsible bag supported within the chamber of the vessel. The fluid can be mixed within bag while the bag is disposed within the vessel.

-

Methods Of Delivering A Fluid Using A Fluid Manifold

view source -

US Patent:20190241287, Aug 8, 2019

-

Filed:Apr 16, 2019

-

Appl. No.:16/385775

-

Inventors:- Carlsbad CA, US

Jeremy K. Larsen - Providence UT, US

Patrick L. Draper - Smithfield UT, US

Brandon M. Knudsen - Hyrum UT, US -

International Classification:B65B 1/04

B65B 3/04

B65B 3/00

B65B 51/22

B65B 51/02

B65B 3/02 -

Abstract:A method of dispensing a fluid includes coupling a manifold to a fluid source, the manifold including at least portions of opposing flexible sheets welded together to form a fluid flow path therebetween; passing a fluid from the fluid source through the fluid flow path of the manifold and into a plurality of flexible bags coupled to the manifold; sealing closed each of the flexible bags; progressively collapsing the fluid flow path along a length of the manifold so as to force a portion of the fluid remaining within the fluid flow path into one of the flexible bags before all of the flexible bags are sealed closed; and removing each sealed bag from the manifold.

-

Compression Collars For Coupling A Tube To A Tube Fitting And Methods Of Use

view source -

US Patent:20180187809, Jul 5, 2018

-

Filed:Jan 5, 2018

-

Appl. No.:15/863031

-

Inventors:- Carlsbad CA, US

Brandon R. Burtenshaw - Logan UT, US

Eric Davis - Smithfield UT, US

Patrick L. Draper - Smithfield UT, US

Michael E. Goodwin - Logan UT, US

Brandon M. Knudsen - Hyrum UT, US

Jeremy K. Larsen - Providence UT, US

Kevin R. Pickup - Paradise UT, US -

International Classification:F16L 33/207

F16L 33/22 -

Abstract:A method for coupling a tube to a tube fitting includes radially outwardly expanding a tubular compression collar from a constricted state to an expanded state, the compression collar having a throughway extending there through and being made of a resiliently flexible material. An end of the tube is inserted within the throughway of the expanded compression collar, the tube bounding a passageway. A tube fitting is inserted within the passageway of the tube. The compression collar is allowed to resiliently rebound back towards the constricted state so that the compression collar pushes the tube against the tube fitting.

-

Methods And Apparatus For Processing Fluids

view source -

US Patent:20160023784, Jan 28, 2016

-

Filed:Oct 8, 2015

-

Appl. No.:14/878299

-

Inventors:- Carlsbad CA, US

Jacob D. Lee - Smithfield UT, US

Whitt F. Woods - North Ogden UT, US

Patrick L. Draper - Smithfield UT, US -

International Classification:B65B 1/02

-

Abstract:A method for processing a fluid includes removably securing a retention member to a vessel that bounds a chamber; inserting a collapsible bag within the chamber of the vessel; securing the bag to the retention member so that the bag is supported within the chamber of the vessel; and dispensing a fluid into a compartment of the collapsible bag supported within the chamber of the vessel. The fluid can be mixed within bag while the bag is disposed within the vessel.

-

Fluid Manifold Systems

view source -

US Patent:20150259082, Sep 17, 2015

-

Filed:Jun 2, 2015

-

Appl. No.:14/728717

-

Inventors:- Carlsbad CA, US

Jeremy K. Larsen - Providence UT, US

Patrick L. Draper - Smithfield UT, US

Brandon M. Knudsen - Hyrum UT, US -

International Classification:B65B 1/04

B65B 51/22

B65B 51/02

B65B 3/04 -

Abstract:A fluid manifold system includes a manifold having at least portions of opposing flexible sheets welded together to form a fluid flow path therebetween, a fluid inlet communicating with the fluid flow path. A plurality of receiving containers are in fluid communication with the fluid flow path of the manifold, each receiving container bounding a compartment. The receiving containers can be formed integral with the manifold by welding together a second portion of the opposing flexible sheets or can comprise separate containers that are coupled to the manifold.

-

Fluid Manifold Systems

view source -

US Patent:20140137519, May 22, 2014

-

Filed:Jul 10, 2012

-

Appl. No.:14/131872

-

Inventors:Michael E. Goodwin - Logan UT, US

Jeremy K. Larsen - Providence UT, US

Patrick L. Draper - Smithfield UT, US

Brandon M. Knudsen - Hyrum UT, US -

Assignee:HYCLONE LABORATORIES, INC. - Logan UT

-

International Classification:B65B 3/02

B65B 3/04 -

US Classification:53456, 141244, 141 10, 53469

-

Abstract:A fluid manifold system includes a manifold having at least portions of opposing flexible sheets welded together to form a fluid flow path therebetween, a fluid inlet communicating with the fluid flow path. A plurality of receiving containers are in fluid communication with the fluid flow path of the manifold, each receiving container bounding a compartment. The receiving containers can be formed integral with the manifold by welding together a second portion of the opposing flexible sheets or can comprise separate containers that are coupled to the manifold.

Googleplus

Patrick Draper

Patrick Draper

Patrick Draper

Patrick Draper

Patrick Draper

Patrick Draper

Patrick Draper

Patrick Draper

view source

Patrick Draper

view source

Patrick Draper

view source

Patrick Draper

view source

Patrick Draper

view source

Patrick Draper

view source

Teresa Patrick Draper

view source

Patrick Draper

view sourceClassmates

Patrick Draper

view sourceSchools:

North Florida Christian High School Tallahassee FL 1985-1989

Community:

Tamesa Hampton, Ronnie Aikens

Patrick Draper

view sourceSchools:

Emerson Junior High School Colorado Springs CO 1984-1986, Harrison Junior High School Colorado Springs CO 1985-1987

Community:

Sara Lucero, Effrim Griffin

Patrick Draper | Emerson ...

view source

Patrick Draper, La Jolla ...

view source

North Florida Christian H...

view sourceGraduates:

Michael Dilmore (1977-1990),

Brian Moret (1977-1981),

Patrick Draper (1979-1986),

Tony Milton (1995-1999)

Brian Moret (1977-1981),

Patrick Draper (1979-1986),

Tony Milton (1995-1999)

La Jolla High School, La ...

view sourceGraduates:

Israel Rivera Morales (1993-1997),

Patrick McDonald (1972-1976),

Patrick Draper (1981-1985),

Belinda Newmichael (1979-1983)

Patrick McDonald (1972-1976),

Patrick Draper (1981-1985),

Belinda Newmichael (1979-1983)

Harrison Junior High Scho...

view sourceGraduates:

Patrick Draper (1985-1987),

Emili Emili (1979-1983),

Garrett Hallworth (2001-2005),

Kellyne Hamner (1975-1977),

Linda Tidwell (1966-1966)

Emili Emili (1979-1983),

Garrett Hallworth (2001-2005),

Kellyne Hamner (1975-1977),

Linda Tidwell (1966-1966)

Minden High School, Minde...

view sourceGraduates:

PATRICK DRAPER (1986-1990),

Jacquetta Hawk (2001-2005),

sandra holland (1961-1965)

Jacquetta Hawk (2001-2005),

sandra holland (1961-1965)

Youtube

Plaxo

Patrick Draper

view sourceAdvisory Software Migration Engineer at IBM

Flickr

Get Report for Patrick L Draper from Smithfield, UT, age ~62