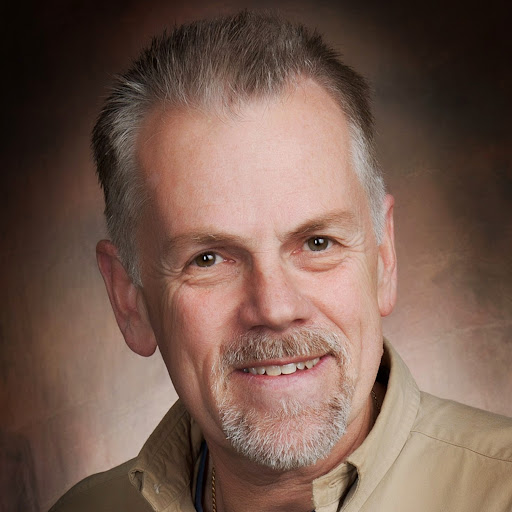

Paul J Swenson

age ~47

from Webster, MA

- Also known as:

-

- Paul J Swonson

- Paul W

- Christina Bailey

- Phone and address:

-

12 Community Rd, Webster, MA 01570

5086126089

Paul Swenson Phones & Addresses

- 12 Community Rd, Webster, MA 01570 • 5086126089

- Hampton, NH

- Leicester, MA

- 298 Clark St, Rochdale, MA 01542

- 105 Oxford St N, Auburn, MA 01501 • 5088328108

- 12 Vinal St, Auburn, MA 01501 • 5088328108

- Evergreen, CO

Work

-

Company:Kortec inc

-

Address:29 Old Right Rd, Ipswich, MA 01938

-

Phones:9782387100

-

Position:Chief executive officer

-

Industries:Industrial Machinery and Equipment

Resumes

Senior Estimator

view sourceWork:

Haselden Constrution

Senior Estimator

Senior Estimator

Skills:

Value Engineering

Construction Management

Construction

Project Estimation

Contract Management

Change Orders

Contractors

Subcontracting

Budgeting

Process Scheduler

Constructability

Microsoft Excel

Microsoft Word

Project Bidding

Budgets

Submittals

Construction Management

Construction

Project Estimation

Contract Management

Change Orders

Contractors

Subcontracting

Budgeting

Process Scheduler

Constructability

Microsoft Excel

Microsoft Word

Project Bidding

Budgets

Submittals

Paul Swenson

view source

Paul Marcia Swenson

view source

Paul Swenson

view source

Paul Swenson

view sourceSkills:

Government Relations

Paul Swenson

view source

Paul Swenson

view sourceLocation:

United States

Paul Swenson

view sourceLocation:

United States

Medicine Doctors

Paul Swenson

view sourceSpecialties:

Family Medicine

Work:

El Rio Community Health CenterEl Pueblo Health Center

101 W Irvington Rd BLDG 10, Tucson, AZ 85714

5205730096 (phone), 5203094576 (fax)

101 W Irvington Rd BLDG 10, Tucson, AZ 85714

5205730096 (phone), 5203094576 (fax)

Education:

Medical School

University of Colorado School of Medicine at Denver

Graduated: 2012

University of Colorado School of Medicine at Denver

Graduated: 2012

Languages:

English

Spanish

Spanish

Description:

Dr. Swenson graduated from the University of Colorado School of Medicine at Denver in 2012. He works in Tucson, AZ and specializes in Family Medicine. Dr. Swenson is affiliated with Carondelet St Marys Hospital and Tucson Medical Center.

Paul Francis Swenson

view sourceSpecialties:

Family Medicine

Isbn (Books And Publications)

The Power of Peervention: A Manual for the Trainers of Peer Facilitators

view sourceAuthor

Paul Swenson

ISBN #

0932796362

Name / Title

Company / Classification

Phones & Addresses

Chief Executive Officer

Kortec Inc

Industrial Machinery and Equipment

Industrial Machinery and Equipment

29 Old Right Rd, Ipswich, MA 01938

CEO

Kortec Inc

Industrial Machinery and Equipment

Industrial Machinery and Equipment

29 Old Right Rd, Ipswich, MA 01938

Website: kortec.com

Website: kortec.com

President, CEO

Kortec

Mfg Misc Industry Machinery · Nonclassifiable Establishments · Business Consulting Services · Industrial Machinery Merchant Whols

Mfg Misc Industry Machinery · Nonclassifiable Establishments · Business Consulting Services · Industrial Machinery Merchant Whols

428 Newbury Tpke, Rowley, MA 01969

428 Newburyport Tpke, Rowley, MA 01969

29 Old Right Rd, Ipswich, MA 01938

9782387100, 9782387171, 9782387167

428 Newburyport Tpke, Rowley, MA 01969

29 Old Right Rd, Ipswich, MA 01938

9782387100, 9782387171, 9782387167

Us Patents

-

Method Of Molding Multi-Layer Polymer Plastic Articles With Control Of Relative Shifting Of The Core Layer

view source -

US Patent:6596213, Jul 22, 2003

-

Filed:Apr 6, 2001

-

Appl. No.:09/828254

-

Inventors:Paul Swenson - Hamilton MA

-

Assignee:Kortec, Inc. - Beverly MA

-

International Classification:B29C 4516

-

US Classification:264255, 2643288, 26432812

-

Abstract:A novel technique for molding multi-layer polymer plastic articles having inner, outer and interior or core layers by controlling relative volumetric flow rates of the inner and outer layers to enable relative shifting of the position of the core, and also the relative thickness of the inner and outer layers in the molded articles; and with leading, and, where desired, trailing ends of the interior layer flow into the mold cavity substantially positioned on the zero gradient of the velocity profile of the flowing polymer streams.

-

Optimized Flow To Prevent Core Layer Breakthrough

view source -

US Patent:6908581, Jun 21, 2005

-

Filed:Jan 31, 2003

-

Appl. No.:10/355642

-

Inventors:Douglas Sabin - Marblehead MA, US

Paul Swenson - South Hamilton MA, US -

Assignee:Kortec, Inc. - Beverly MA

-

International Classification:B29C045/16

-

US Classification:264255, 2643288, 26432812

-

Abstract:A method of co-extruding a plurality of plastic material flowing streams into a mold cavity produces a molded product. Inner and outer streams of covering plastic materials are combined with at least one interior stream that is to serve as an interior core of a resulting molded plastic product. The combined streams are forced to flow along annular flow paths, with the annular interior stream encased within the inner and outer annular covering plastic material stream layers. The flows of the interior stream and the inner and outer streams are controlled so that: the interior stream has a flow velocity that is greater than an average velocity of the combined stream, and the interior stream does not flow along or across a zero-velocity-gradient streamline of the combined streams.

-

Co-Injection Nozzle With Improved Interior Layer Termination

view source -

US Patent:7306446, Dec 11, 2007

-

Filed:May 21, 2004

-

Appl. No.:10/851284

-

Inventors:Douglas Sabin - Marblehead MA, US

Paul Swenson - South Hamilton MA, US

Ronald Roberts - Melrose MA, US -

Assignee:Kortec, Inc. - Ipswich MA

-

International Classification:B29C 45/23

-

US Classification:425130, 425564, 425572

-

Abstract:Disclosed herein are a method and apparatus for combining two or more streams of a polymeric material to form a plastic object. The method and apparatus are capable of ending an interior layer of the plastic object at a desired length to avoid the need to clean selected surfaces of components used to form the plastic object. The method and apparatus increase the velocity of the polymeric material used to form the plastic object in certain components used to form the plastic object. The increase in the velocity of the polymeric material facilitates the ending of the interior layer of the plastic object.

-

Multilayer Molding Using Temperature Adjustment Of Flow Rate In Conjunction With Shooting Pot Technology

view source -

US Patent:7399442, Jul 15, 2008

-

Filed:Jul 7, 2005

-

Appl. No.:11/177464

-

Inventors:Douglas Sabin - Marblehead MA, US

Paul Swenson - South Hamilton MA, US

Ronald Roberts - Melrose MA, US -

Assignee:Kortec, Inc. - Ipswich MA

-

International Classification:B29C 45/22

-

US Classification:2643288, 425130

-

Abstract:Disclosed herein are methods and systems for forming a plurality of multiple layer plastic articles. The methods and systems utilize shooting pot technology in combination with a combination of thermal control elements and in some instances, specialized flow bore geometries to control a thermal property and a flow parameter of selected polymeric material flowing through the system to mold the plurality of multiple layer plastic articles. Both the systems and methods are well suited for use to perform simultaneous flow injection or sequential flow injection to form the plurality of multiple layer plastic articles. The systems and methods described therein beneficially reduce the mold cavity pitch size for multiple layer molds used with systems having shooting pot technology to a mold cavity pitch size found on conventional monolayer molds to provide a plurality of multiple layer plastic articles having a cost similar to monolayer plastic articles.

-

Automatic Process Control For A Multilayer Injection Molding Apparatus

view source -

US Patent:7517480, Apr 14, 2009

-

Filed:Aug 18, 2004

-

Appl. No.:10/920725

-

Inventors:Douglas Sabin - Marblehead MA, US

Paul Swenson - South Hamilton MA, US -

Assignee:Kortec, Inc. - Ipswich MA

-

International Classification:B29C 45/76

-

US Classification:264 401, 700200, 264 406, 425144, 425172

-

Abstract:A control system for use with a multi-layer molding device having an inspection device for measuring a characteristic of a product of a cavity of the molding device and a controller adapted to receive information corresponding to the at least one characteristic from the inspection device and to alter the molding device based on the information.

-

Molding Structure

view source -

US Patent:7695266, Apr 13, 2010

-

Filed:Nov 2, 2006

-

Appl. No.:11/555913

-

Inventors:Jeffrey Douglas MacDonald - North York, CA

Adam Craig Reynolds - Bolton, CA

Paul Michael Swenson - South Hamilton MA, US

John Nicholas Kermet - Danvers MA, US -

Assignee:Husky Injection Molding Systems Ltd. - Bolton, ON

-

International Classification:B29C 45/10

B29C 45/16 -

US Classification:425130, 2643288, 425 88, 425192 R, 425213, 425542

-

Abstract:Disclosed is a molding structure, amongst other things.

-

Method Of Molding

view source -

US Patent:8075828, Dec 13, 2011

-

Filed:Jan 7, 2010

-

Appl. No.:12/683866

-

Inventors:Jeffrey Douglas MacDonald - North York, CA

Adam Craig Reynolds - Bolton, CA

Paul Michael Swenson - South Hamilton MA, US

John Nicholas Kermet - Danvers MA, US -

Assignee:Husky Injection Molding Systems Ltd. - Bolton, Ontario

-

International Classification:B29C 45/10

B29C 45/16 -

US Classification:2643281, 2643288

-

Abstract:Disclosed is a method of molding molded articles, amongst other things.

-

Non-Symmetric Multiple Layer Injection Molded Products And Methods

view source -

US Patent:8435434, May 7, 2013

-

Filed:Dec 7, 2011

-

Appl. No.:13/314012

-

Inventors:Paul M. Swenson - South Hamilton MA, US

-

Assignee:Kortec, Inc. - Rowley MA

-

International Classification:B29C 45/16

-

US Classification:264250, 2643288, 26432812

-

Abstract:A mold for molding an injection molded article comprises a mold cavity with a non-symmetrical portion. At least one flow leader in the non-symmetrical portion of the cavity may produce a symmetrical flow boundary in a multilayer flow downstream of the non-symmetrical portion of the mold cavity. The at least one flow leader may be a plurality of flow leaders having a flow path length that differs from the flow path length of an adjacent flow leader by no more than about 15%. The multilayer flow comprising an inner layer, an outer layer, and an interior layer. Co-injection molding apparatus and methods that may use the foregoing mold are disclosed. Similarly, co-injection molded articles and containers that may result from the foregoing mold, apparatus, and methods are disclosed.

Plaxo

Swenson, Paul

view sourceFinancial Advisor at martinwight company llc

Guy Paul Swenson

view sourceAustin, TX

Classmates

Paul Swenson

view sourceSchools:

Elbow Lake-West Central High School Elbow Lake MN 1973-1977

Community:

Carl Paetow, Dennis Bah, Ernest Leivestad, Marion Johnson

Paul Swenson

view sourceSchools:

Sunset High School San Antonio TX 1995-1999

Community:

Kelly Burford, Jennifer Waters

Paul Swenson

view sourceSchools:

Onida High School Onida SD 1961-1965

Community:

Jo Williams, Kenneth Kost, Jean Sargent, Helen Howard, Gary Holloway, Larry Mayes, Myron Phares, Nancy Rempfer, Barbara Kellogg, Jesse Comde, Doug Marsh, Pamela Birdsall

Paul Swenson

view sourceSchools:

Willmar High School Willmar MN 1990-1994

Community:

Nyssa Olsen, Ryna Gaylor, Jason Crowe, Jay Kocka, Brian Carlson, Peter Barrientos, Mark Rodriguez, Allison Rice, Kelly Anderson, Matthew Erickson, Brian Klause, Amy Norby

Paul Swenson

view sourceSchools:

Sheridan Hills Elementary School Richfield MN 1972-1979, St. Peter's School Richfield MN 1974-1975, Pequot Lakes Elementary School Pequot Lakes MN 1975-1976, Ironton Elementary School Crosby MN 1976-1979, Crosby-Ironton Junior High School Crosby MN 1979-1982

Community:

Sharon Kern, Jerry Stirewalt, Lori Wassen, Rich Curren, Nancy Mount, Mary Endrizzi, Charlotte Stimack, James Tscheu, Eric Larson, William Adams, David Dotzler

Crosby-Ironton Junior Hig...

view sourceGraduates:

Valene Perpich (1974-1977),

Tamsyn Dalton (1994-1996),

Paul Swenson (1979-1982),

Tammy Woodcock (1980-1983),

Rhonda Mcgregor (1970-1972)

Tamsyn Dalton (1994-1996),

Paul Swenson (1979-1982),

Tammy Woodcock (1980-1983),

Rhonda Mcgregor (1970-1972)

St. Peter's School, Richf...

view sourceGraduates:

Paul Carter (1985-1989),

Courtney Simons (1987-1990),

Paul Barcomb (1980-1982),

Paul Swenson (1974-1975)

Courtney Simons (1987-1990),

Paul Barcomb (1980-1982),

Paul Swenson (1974-1975)

Youtube

Myspace

Googleplus

Paul Swenson

Paul Swenson

Paul Swenson

Paul Swenson

Paul Swenson

Paul Swenson

Paul Swenson

Paul Swenson

Paul Richard Swenson

view source

Paul Swenson

view source

Paul Swenson

view source

Paul Swenson

view source

Paul Swenson

view source

Paul Swenson

view source

Paul Swenson

view source

Paul Swenson

view sourceFlickr

Get Report for Paul J Swenson from Webster, MA, age ~47