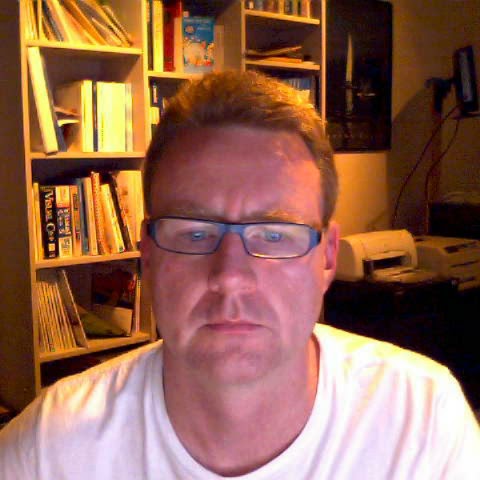

Richard A Crowe

age ~66

from Tampa, FL

- Also known as:

-

- Richard Anthony Crowe

- Richard A Crowfe

- Rick Crowe

- Anthony Crowe

- Dick Crowe

- Phone and address:

-

15902 Ellsworth Dr, Tampa, FL 33647

8139790940

Richard Crowe Phones & Addresses

- 15902 Ellsworth Dr, Tampa, FL 33647 • 8139790940

- Temple Terrace, FL

- Irving, TX

- Jamaica, NY

- 15902 Ellsworth Dr, Tampa, FL 33647

Work

-

Position:Sales Occupations

Education

-

Degree:Bachelor's degree or higher

Resumes

Vice Chairman & General Counsel At Embree Group

view sourceLocation:

United States

Industry:

Construction

Event Coordinator At Kahn's Catering

view sourceLocation:

United States

Manager

view sourceLocation:

Tampa, FL

Industry:

Financial Services

Work:

Ascensus

Manager

Manager

Education:

University of South Florida

Bachelors, Accounting

Bachelors, Accounting

Certifications:

Certified Public Accountant

Florida Institute of Cpas (Ficpa)

Florida Institute of Cpas (Ficpa)

Richard Crowe

view sourceIndustry:

Higher Education

Work:

University of Hawaii Fndtn

Vice President

University of Hawaii

Chief Executive Officer

University of Hawaii

Professor of Astronomy

Vice President

University of Hawaii

Chief Executive Officer

University of Hawaii

Professor of Astronomy

Education:

Western University 1970 - 1977

Richard Crowe

view source

Richard Crowe

view source

Richard Crowe

view source

Richard Crowe

view sourceLawyers & Attorneys

License Records

Richard Alan Crowe

License #:

PT00496 - Active

Category:

Physical Therapy

Issued Date:

Oct 15, 1982

Expiration Date:

May 1, 2018

Type:

Physical Therapist

Richard Anthony Crowe

Address:

15902 Ellsworth Dr, Tampa, FL 33647

License #:

AC0017537 - Active

Category:

Certified Public Accounting

Issued Date:

Sep 18, 1986

Effective Date:

Jan 2, 2010

Expiration Date:

Dec 31, 2017

Type:

Accountant

Richard Alan Crowe

License #:

PT00496 - Active

Category:

Physical Therapy

Issued Date:

Oct 15, 1982

Expiration Date:

Jan 5, 2018

Type:

Physical Therapist

Richard J Crowe

License #:

RS072408A - Expired

Category:

Real Estate Commission

Type:

Real Estate Salesperson-Standard

Name / Title

Company / Classification

Phones & Addresses

Director, Secretary

Embree Asset Group, Inc

Director

Texas Bankers Association

Business Association

Business Association

5124728388

Treasurer

Hillsborough County School District

School/Educational Services

School/Educational Services

17410 Commerce Park Blvd, Tampa, FL 33647

ALL Officers

CROWE MANAGEMENT, INC

President, Director

Datalogic Associates, Inc

16 Wakefield Rd, Staten Island, NY 10312

Vice President

Suncoast Pension & Benefits Group Inc

Pension and Retirement Fund Administrator

Pension and Retirement Fund Administrator

508 W Fletcher Ave, Tampa, FL 33612

105 Eisenhower Pkwy, Roseland, NJ 07068

PO Box 82040, Tampa, FL 33682

105 Eisenhower Pkwy, Roseland, NJ 07068

PO Box 82040, Tampa, FL 33682

President, Director

WAKEFIELD SECURITIES CORPORATION

5215 N Oconnor Blvd #530, Irving, TX 75039

5215 N O'connor Blvd, Irving, TX 75039

4 Shields Ct, Roanoke, TX

5215 N O'connor Blvd, Irving, TX 75039

4 Shields Ct, Roanoke, TX

Treasurer

Lady "G" Coffee Shop, Inc

6441 Reef Cir, Tampa, FL 33625

Us Patents

-

Chemical Processing Using Non-Thermal Discharge Plasma

view source -

US Patent:6923890, Aug 2, 2005

-

Filed:Aug 2, 2002

-

Appl. No.:10/211980

-

Inventors:Pascal J. Ricatto - Ridgewood NJ, US

Edward J. Houston - East Brunswick NJ, US

Richard Crowe - Hazlet NJ, US -

Assignee:PlasmaSol Corporation - Hoboken NJ

-

International Classification:D06M011/00

C01G015/12

C01B003/24

B01J019/08 -

US Classification:204164, 811551, 811552, 204165, 208 46, 423650, 423655

-

Abstract:A method for activating chemical reactions using a non-thermal capillary discharge plasma (NT-CDP) unit or a non-thermal slot discharge plasma (NT-SDP) unit (collectively referred to as “NT-CDP/SDP”). The NT-CDP/SDP unit includes a first electrode disposed between two dielectric layers, wherein the first electrode and dielectric layers having at least one opening (e. g. , capillary or a slot) defined therethrough. A dielectric sleeve inserted into the opening, and at least one second electrode (e. g. , in the shape of a pin, ring, metal wire, or tapered metal blade) is disposed in fluid communication with an associated opening. A non-thermal plasma discharge is emitted from the opening when a voltage differential is applied between the first and second electrodes. Chemical feedstock to be treated is then exposed to the non-thermal plasma. This processing is suited for the following exemplary chemical reactions as (i) partial oxidation of hydrocarbon feedstock to produce functionalized organic compounds; (ii) chemical stabilization of a polymer fiber (e. g.

-

Electrode Discharge, Non-Thermal Plasma Device (Reactor) For The Pre-Treatment Of Combustion Air

view source -

US Patent:7029636, Apr 18, 2006

-

Filed:Aug 2, 2002

-

Appl. No.:10/211936

-

Inventors:Pascal J. Ricatto - Ridgewood NJ, US

Edward J. Houston - East Brunswick NJ, US

Richard Crowe - Hazlet NJ, US -

Assignee:Plasmasol Corporation - Hoboken NJ

-

International Classification:B01J 19/08

-

US Classification:42218604, 204177, 60275

-

Abstract:A device for the pre-treatment of combustion air by exposure to non-thermal plasma at substantially atmospheric pressure and a method for operating the same. The device includes an inner electrode having a longitudinal channel defined therein to receive a fuel. An outer dielectric layer is separated a predetermined distance from the inner electrode so as to form a non-thermal atmospheric pressure plasma region therebetween for receiving the combustion air to be treated. The outer dielectric has at least one opening (e. g. , capillaries or slots) defined therethrough from which the non-thermal plasma is emitted. At least one outer electrode (e. g. , in the shape of a pin or ring) is disposed in fluid communication with the at least one opening. The treated combustion air and fuel are combined in a mixing region. The pretreatment device may be disposed in an unsealed or a sealed combustion burner.

-

Electrode For Use With Atmospheric Pressure Plasma Emitter Apparatus And Method For Using The Same

view source -

US Patent:7098420, Aug 29, 2006

-

Filed:Jul 2, 2002

-

Appl. No.:10/188690

-

Inventors:Richard Crowe - Hazlet NJ, US

Sergei Babko-Malyi - West Windsor NJ, US

Kurt Kovach - Highlands NJ, US

Seth Tropper - Old Bridge NJ, US -

Assignee:Plasmasol Corporation - Hoboken NJ

-

International Classification:B23K 10/00

-

US Classification:21912143, 21912157

-

Abstract:A plasma emitter apparatus and method for using the same that includes a primary electrode and a secondary electrode. The secondary electrode is porous, that is, it is configured to permit the passage of plasma discharge therethrough. Accordingly, the plasma is received at one side of the secondary electrode and emitted from its opposing plasma exiting side. The secondary electrode may be a laminate of multiple insulating material layers with at least one conductive layer sandwiched therebetween. A plurality of apertures are defined through the laminate and a dielectric sleeve is inserted into and retained in the aperture. The generated plasma passes through one or more holes defined in each of the dielectric sleeves. Alternatively, the secondary electrode may be formed as a plurality of unidirectional high voltage wires strung substantially parallel across a frame or a plurality of bidirectional high voltage wires interwoven and secured by a perimeter frame.

-

In Situ Sterilization And Decontamination System Using A Non-Thermal Plasma Discharge

view source -

US Patent:7192553, Mar 20, 2007

-

Filed:Nov 4, 2002

-

Appl. No.:10/287771

-

Inventors:Richard Crowe - Hazlet NJ, US

George Korfiatis - Basking Ridge NJ, US

Sergei Babko-Malyi - West Windsor NJ, US -

Assignee:Plasmasol Corporation - Hoboken NJ

Stevens Institute of Technology - Hoboken NJ -

International Classification:A61L 2/00

-

US Classification:422 23, 422 22, 422 28, 422 29

-

Abstract:A sterilization and decontamination system in which a non-thermal plasma discharge device is disposed upstream of a suspension media (e. g. , a filter, electrostatic precipitator, carbon bed). The plasma discharge device generates a plasma that is emitted through apertures (e. g. , capillaries or slits) in the primary dielectric. Plasma generated active sterilizing species when exposed to contaminants or undesirable particulate matter is able to deactivate or reduce such matter in contaminated fluid stream and/or on objects. Thus, the undesirable contaminants in the fluid to be treated are first reduced during their exposure to the plasma generated active sterilizing species in the plasma region of the discharge device. Furthermore, the plasma generated active sterilizing species are carried downstream to suspension media and upon contact therewith deactivate the contaminants collected on the suspension media itself. Advantageously, the suspension media may be cleansed in situ.

-

In Situ Sterilization And Decontamination System Using A Non-Thermal Plasma Discharge

view source -

US Patent:20080063577, Mar 13, 2008

-

Filed:Feb 21, 2007

-

Appl. No.:11/677378

-

Inventors:Richard Crowe - Hazlet NJ, US

George Korfiatis - Basking Ridge NJ, US

Sergei Babko-Malyi - West Windsor NJ, US -

Assignee:STEVENS INSTITUTE OF TECHNOLOGY - Hokoken NJ

PLASMASOL CORPORATION - Hokoken NJ -

International Classification:B01J 19/12

H05H 1/24 -

US Classification:422186040

-

Abstract:A sterilization and decontamination system in which a non-thermal plasma discharge device is disposed upstream of a suspension media (e.g., a filter, electrostatic precipitator, carbon bed). The plasma discharge device generates a plasma that is emitted through apertures (e.g., capillaries or slits) in the primary dielectric. Plasma generated active sterilizing species when exposed to contaminants or undesirable particulate matter is able to deactivate or reduce such matter in contaminated fluid stream and/or on objects. Thus, the undesirable contaminants in the fluid to be treated are first reduced during their exposure to the plasma generated active sterilizing species in the plasma region of the discharge device. Furthermore, the plasma generated active sterilizing species are carried downstream to suspension media and upon contact therewith deactivate the contaminants collected on the suspension media itself. Advantageously, the suspension media may be cleansed in situ. To increase the sterilization efficiency an additive, free or carrier gas (e.g., alcohol, water, dry air) may be injected into the apertures defined in the primary dielectric. These additives increase the concentration of plasma generated active sterilizing agents while reducing the byproduct of generated undesirable ozone pollutants. Downstream of the filter the fluid stream may be further treated by being exposed to a catalyst media or additional suspension media to further reduce the amount of undesirable particulate matter.

Youtube

Myspace

Richard Crowe (Richard) ...

view sourceRichard Crowe (Richard)'s profile on Myspace, the leading social entertainment destination powered by the passion of our fans.

Flickr

Plaxo

Richard Crowe

view sourceFresno, CaliforniaDirector BRAC & Enhanced Use Developemnt Office at...

Richard Crowe

view sourcePrincipal at Booz Allen & Hamilton Past: Chief Technical Officer at PlasmaSol, Account Executive at United Technologies...

Classmates

Richard Crowe

view sourceSchools:

Troup Junior High School Lagrange GA 1977-1978

Richard Crowe

view sourceSchools:

Remington High School Remington IN 1958-1962

Community:

Trena Pelsy, Joan Harries, Rita Adamson

Richard Crowe

view sourceSchools:

Eastern District High School Bloomfield IN 1977-1981

Community:

Harold Allen

Richard Beck (Crowe)

view sourceSchools:

Frayser Baptist High School Memphis TN 1971-1975

Community:

Phoebe Cox, Steve Sigman

Richard Crowe

view sourceSchools:

Franklin Community High School Franklin IN 1971-1975

Community:

Mike Porterfield

Richard Crowe

view sourceSchools:

Burton High School Burton OH 1956-1960

Community:

Gale Bartholomew, Susan Rogers, Rose Castilyn, Charles Milliken, Jeanette Williams

Richard Crowe

view sourceSchools:

Northeast Metropolitan High School Wakefield MA 1976-1980

Community:

Deborah Sekenski, Joe Callahan, Christopher Smith, Silvia Pontoriero, Karen Cummings, Susan Darling, Scott Seaver, Geri Bechat

Richard Crowe

view sourceSchools:

Blessed Sacrament School Providence RI 1941-1951

Community:

Stephen Sako, Anthony Fiore, Arlene Gemma, Lois Fink, Letitia Verona, Vincenza Pettinato, Eleanor Kelly, Louis Scorpio, Myrna Corsi, Richard Haskins

Googleplus

Richard Crowe

Work:

Ford Motor Company - APA Facilities & Hosting Analyst

Richard Crowe

Richard Crowe

Richard Crowe

Richard Crowe

Richard Crowe

Richard Crowe

Richard Crowe

Richard Crowe

view source

Richard Crowe

view source

Richard W Crowe

view source

Richard Crowe

view source

Richard D Crowe

view source

Richard T Crowe

view source

Richard W. Crowe

view source

Richard Crowe

view sourceGet Report for Richard A Crowe from Tampa, FL, age ~66