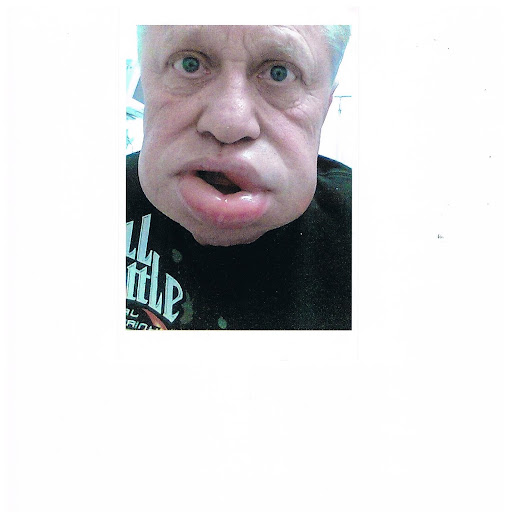

Robert Kolb

age ~50

from San Jacinto, CA

- Also known as:

-

- Rober Kolb

- Stacey Kolb

Robert Kolb Phones & Addresses

- San Jacinto, CA

- Kansas City, MO

- Hemet, CA

- Desert Hot Springs, CA

Lawyers & Attorneys

Robert Kolb - Lawyer

view sourceOffice:

Latina, Inc.

Specialties:

Uniform Commercial Code Law

Importing Chemicals

Importing Chemicals

ISLN:

905789758

Admitted:

1971

University:

St Johns; St Johns

Robert Kolb - Lawyer

view sourceISLN:

905789741

Admitted:

1971

University:

Golden Gate University, B.B.A.

Law School:

San Francisco Law School, J.D.

Us Patents

-

Three Stage Single Pass High Density Drying Apparatus For Particulate Materials

view source -

US Patent:6584699, Jul 1, 2003

-

Filed:May 15, 2001

-

Appl. No.:09/858013

-

Inventors:Richard L. Ronning - Overland Park KS

Robert Kolb - Olathe KS -

Assignee:Ronning Engineering, Co., Inc. - Overland Park KS

-

International Classification:F26B 1102

-

US Classification:34134, 34318, 34 63, 34108, 34109, 34115, 34602, 34604, 34135

-

Abstract:A single pass, multiple stage, rotary drum heat exchange dryer ( ) is provided for drying products such as distillers grains and includes a tubular shell ( ) with a moist product inlet ( ), an opposed dried product outlet ( ), and an internal drying chamber ( ). The chamber ( ) includes a convection drying first stage ( ), and conductive drying final curing stage ( ) an intermediate stage ( ); the stage ( ) is subdivided into a plurality of preferably contiguous drying zones ( ). The zones ( ) include individual flighting assemblies ( ) which are of increasing density and present progressively increasing heat transfer ratios. Preferably, one of the initial zones has a heat transfer ratio of from about 1. 5-2. 5 ft , whereas another of the zones closer to the final stage has a heat transfer of from about 2. 75-3. 75 ft.

-

Centrifugal Separator Apparatus For Removing Particulate Material From An Air Stream

view source -

US Patent:6589306, Jul 8, 2003

-

Filed:Jul 18, 2001

-

Appl. No.:09/908260

-

Inventors:Richard L. Ronning - Overland Park KS

Robert Kolb - Olathe KS -

Assignee:Ronning Engineering Co., Inc. - Overland Park KS

-

International Classification:B01D 4512

-

US Classification:55349, 554591

-

Abstract:Horizontal, negative pressure centrifugal separator apparatus ( ) is provided for separating particulate material from an air stream that exhausts from the outlet of a horizontal, industrial size, rotary drum dryer ( ). The centrifugal separator is especially adapted to be connected to the negative pressure inlet of a primary fan ( ) which pulls large volumes of air through the rotary drum dryer. The separator apparatus includes wall structure which defines two aligned primary spiral separation plenum chambers (e. g. ) joined to an intermediate spiral discharge plenum chamber (e. g. ), all of which intercommunicate. A pair of oppositely facing plenum chamber divider members each having a central aperture therein are mounted in the plenum chambers on opposite sides of the discharge plenum chamber and function as pressure regain stacks. Air streams containing particulate materials which are introduced into the air inlets of the primary separation plenum chambers each follow a serpentine path in a respective primary chamber before flowing through a corresponding plenum chamber divider member spiral velocity regain stack into the spiral chamber of the discharge plenum chamber. Discharge openings are provided in the primary spiral plenum chambers in positions permitting particulate material separated from the air stream as a result of centrifugal force thereon, to gravitate to a collection point therebelow.

Name / Title

Company / Classification

Phones & Addresses

President

Ronning Engineering Co Inc

Packaging and Containers · Engineering Services · Engineering Svcs

Packaging and Containers · Engineering Services · Engineering Svcs

7304 W 130 St #150, Shawnee Mission, KS 66213

7304 W 130 St, Overland Park, KS 66213

9132398118, 9132398119

7304 W 130 St, Overland Park, KS 66213

9132398118, 9132398119

BCS CONSULTING LLC

BNC ELECTRONICS, LLC

GREAT LAKES DOG TRAINING, LLC

Resumes

Engineering Manager At Black & Veatch

view sourceLocation:

Kansas City, Missouri Area

Industry:

Oil & Energy

Robert Kolb

view sourceMedicine Doctors

Robert M. Kolb

view sourceSpecialties:

Emergency Medicine

Work:

Emergency Physicians Professional Associates

5435 Feltl Rd, Hopkins, MN 55343

9528359880 (phone), 9528354403 (fax)

5435 Feltl Rd, Hopkins, MN 55343

9528359880 (phone), 9528354403 (fax)

Education:

Medical School

A.T. Still University of Health Sciences/ Kirksville College of Osteopathic Medicine

Graduated: 2005

A.T. Still University of Health Sciences/ Kirksville College of Osteopathic Medicine

Graduated: 2005

Languages:

English

Description:

Dr. Kolb graduated from the A.T. Still University of Health Sciences/ Kirksville College of Osteopathic Medicine in 2005. He works in Minnetonka, MN and specializes in Emergency Medicine.

Isbn (Books And Publications)

Elements of War Crimes Under the Rome Statute of the International Criminal Court: Sources and Commentary

view sourceAuthor

Robert Kolb

ISBN #

0521818524

Andreae and the Formula of Concord: Six Sermons on the Way to Lutheran Unity

view sourceAuthor

Robert Kolb

ISBN #

0570037417

Confessing the Faith: Reformers Define the Church, 1530-1580

view sourceAuthor

Robert Kolb

ISBN #

0570045568

Solutions Manual to Accompany Futures, Options and Swaps

view sourceAuthor

Robert Kolb

ISBN #

0631216197

Robert Kolb

view source

Robert Kolb

view source

Robert Kolb

view source

Robert Kolb

view source

Robert Kolb

view source

Robert Kolb

view source

Robert Kolb

view source

Robert Kolb

view sourceYoutube

Plaxo

Robert Kolb

view sourceClassmates

Robert Kolb

view sourceSchools:

Carmel High School Carmel IN 1983-1987

Community:

Brook Myers, Paula Hatcher

Robert Kolb

view sourceSchools:

Accident High School Accident MD 1945-1949

Community:

Earle Edmunds, George Robertson

Robert Kolb

view sourceSchools:

Columbian Grammar School East Orange NJ 1948-1957

Community:

Joseph Quinn

Robert Kolb

view sourceSchools:

Spring Valley High School Spring Valley NY 1950-1954

Community:

Mark Katz

Robert Kolb

view sourceSchools:

Tilghman High School Paducah KY 1966-1970

Robert Kolb

view sourceSchools:

Bowen High School Bowen IL 1943-1947

Community:

Matt English, Karen Brown

Robert Kolb

view sourceSchools:

Exeter High School Exeter PA 1958-1962

Community:

Deborah Robison, Jill Impink

Robert Kolb

view sourceSchools:

Ascension School Oak Park IL 1956-1961

Community:

Matt Peters, Michael Mike, John Vranicar, John Moran, Nicholas Esposito, Brenda Farmer, Nick Becker, John Clarke, Charles Miller, Pat Barney

Myspace

Flickr

Googleplus

Robert Kolb

Robert Kolb

Robert Kolb

Robert Kolb

Robert Kolb

Robert Kolb

Robert Kolb

Robert Kolb

Get Report for Robert Kolb from San Jacinto, CA, age ~50