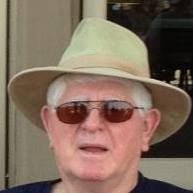

Robert F Metcalf

age ~75

from Salem, OR

- Also known as:

-

- Robert Frederick Metcalf

- Robert A Metcalf

- Robert D Metcalf

- Robert E Metcalf

- Robert F Demonnin

- Robert D Monnin

- Robert De

- Robert F

- Robert De A

- Metcalf Robert Monnin

- Phone and address:

- 4281 Grayce Ct SE, Salem, OR 97317

Robert Metcalf Phones & Addresses

- 4281 Grayce Ct SE, Salem, OR 97317

- Portland, OR

Ranks

-

Licence:Virginia - Authorized to practice law

-

Date:1976

Lawyers & Attorneys

Robert Cole Metcalf - Lawyer

view sourceLicenses:

Virginia - Authorized to practice law 1976

Isbn (Books And Publications)

Destructive and Useful Insects: Their Habits and Control

view sourceAuthor

Robert L. Metcalf

ISBN #

0070416923

Advances in Environmental Science and Technology

view sourceAuthor

Robert L. Metcalf

ISBN #

0471064807

The Future for Insecticides: Needs and Prospects Proceedings of a Rockefeller Foundation Conference, Bellagio, Italy, April 22-27, 1974

view sourceAuthor

Robert Lee Metcalf

ISBN #

0471598607

Making Stained Glass: A Handbook for the Amateur and the Professional

view sourceAuthor

Robert Metcalf

ISBN #

0070416605

Name / Title

Company / Classification

Phones & Addresses

Principal

Will DO LLC

Business Services at Non-Commercial Site

Business Services at Non-Commercial Site

7810 SW Danielle Ave, Beaverton, OR 97008

Town of Dartmouth

Executive Office · Public Finance/Taxation/Monetary Policy · Zoning Board of Appeals · Park Department · Land/Mineral/Wildlife Conservation Executive Office · Treasurer's Office · Planning Board · Assessor's Office

Executive Office · Public Finance/Taxation/Monetary Policy · Zoning Board of Appeals · Park Department · Land/Mineral/Wildlife Conservation Executive Office · Treasurer's Office · Planning Board · Assessor's Office

5089101802, 5089101824, 5089101812

Us Patents

-

Can Coater/Decorator Mandrel System

view source -

US Patent:49267884, May 22, 1990

-

Filed:Jan 2, 1987

-

Appl. No.:7/000202

-

Inventors:Robert L. Metcalf - Beaverton OR

-

Assignee:Wilbanks International, Inc. - Hillsboro OR

-

International Classification:B05C 1302

-

US Classification:118500

-

Abstract:A mandrel system for a can coating or decorating machine or the like comprising a ceramic sleeve member for supporting a workpiece and a sleeve support core member for supporting the ceramic sleeve member and at least two axially spaced bearing units supported by the sleeve support core member and/or the support core member.

-

Semiconductor Wafer Polishing Machine And Method

view source -

US Patent:59803673, Nov 9, 1999

-

Filed:Nov 12, 1997

-

Appl. No.:8/967881

-

Inventors:Robert L. Metcalf - Beaverton OR

-

International Classification:B24C 4700

-

US Classification:451285

-

Abstract:A semiconductor wafer polishing machine and method are described in which a motor driven rotating spindle is coupled to the wafer carrier by a flexible coupling element. The carrier is releasably attached to a load transfer plate by a vacuum pressure chamber to enable removal of the carrier for loading and unloading of wafers prior to and after polishing. The motor and spindle together with the load transfer plate and carrier are moved between and raised rest position and a lowered polish position by a positioning cylinder. A load pressure bellows applies a polishing load force to the load transfer plate through an air lubricated thrust bearing to urge the wafers on the carrier against a rotating polishing table for polishing the wafers. The air bearing isolates the load force of the bellows from the rotational force of the spindle and allows sliding movement of the load plate relative to the bellows. The carrier, load transfer plate and the polishing table may all be made of rigid foam material, such as metal or ceramic, in order to reduce the mass and weight of these elements while providing them with a strong rigid construction.

-

Cyclone Separator Having Abrasion Resistant Cone Covered By A Plastic Sleeve With Flexible Seal Regions

view source -

US Patent:45391050, Sep 3, 1985

-

Filed:Nov 17, 1983

-

Appl. No.:6/553320

-

Inventors:Robert L. Metcalf - Beaverton OR

-

Assignee:Wilbanks International, Inc. - Hillsboro OR

-

International Classification:B04C 528

-

US Classification:209211

-

Abstract:Cyclone separator apparatus and method of manufacture are described for providing a separator cone of abrasion resistant material covered by a sleeve of plastic material having flexible seal regions at least some of which are spaced from the outer surface of the cone. The cover sleeve of plastic is bonded to the cone of abrasion resistant material which is preferably made of aluminum oxide ceramic material, by heating the cone to a temperature above the melting temperature of the plastic, inserting the heated cone into the sleeve to melt the inner surface of the sleeve and cooling the assembly below such melting temperature to bond the sleeve to the cone. The sleeve may be made of polyethylene or other suitable thermoplastic or thermosetting plastic materials and the cleaner cone can be made of ceramic material, metal or other suitable abrasion resistant materials of high melting temperature than the plastic sleeve. As a result of the flexible seal regions formed by circular ridge projections on the outer surface of the plastic sleeve, the cyclone cleaner cone can be inserted through three mounting apertures in the walls of pressure chambers and sealed to wall flanges surrounding the apertures even though such apertures are not in exact alignment and the cleaner cone is not exactly symmetrical.

-

Drainage Foil Apparatus With Individually Replaceable Ceramic Segments

view source -

US Patent:41849159, Jan 22, 1980

-

Filed:Dec 8, 1978

-

Appl. No.:5/967864

-

Inventors:Robert L. Metcalf - Beaverton OR

-

Assignee:Wilbanks International, Inc. - Hillsboro OR

-

International Classification:D21F 148

D21F 154 -

US Classification:162352

-

Abstract:A drainage foil apparatus for removing liquid from material carried across the foil by a moving foraminous conveyor such as the wood pulp stock in a paper making machine, is described. The drainage foil apparatus includes a foil having at least a nose portion of ceramic material formed by laterally spaced ceramic segments. The segments are mounted on a support means enabling individual replacement of such segments when they become damaged or worn. The support means includes a mounting member of metal which extends into a slot in a lower surface portion of the ceramic segment and is bonded thereto by a bonding material provided within the slot. For easy replacement of the ceramic segments, the mounting member and slot are shaped to enable each segment to be inserted and removed from such mounting member without moving other segments. In one embodiment, the ceramic nose portion is separate from the rear portion of the foil, such rear portion being made of a different material such as a synthetic plastic. In another embodiment, both the nose portion and the rear portion of the foil are made integral with the same ceramic member.

-

Semiconductor Wafer Polishing Machine And Method

view source -

US Patent:57162581, Feb 10, 1998

-

Filed:Nov 26, 1996

-

Appl. No.:8/753517

-

Inventors:Robert L. Metcalf - Beaverton OR

-

International Classification:B24C 4700

-

US Classification:451 41

-

Abstract:A semiconductor wafer polishing machine and method are described in which a motor driven rotating spindle is coupled to the wafer carrier by a flexible coupling element. The carrier is releasably attached to a load transfer plate by a vacuum pressure chamber to enable removal of the carrier for loading and unloading of wafers prior to and after polishing. The motor and spindle together with the load transfer plate and carrier are moved between and raised rest position and a lowered polish position by a positioning cylinder. A load pressure bellows applies a polishing load force to the load transfer plate through an air lubricated thrust bearing to urge the wafers on the carrier against a rotating polishing table for polishing the wafers. The air bearing isolates the load force of the bellows from the rotational force of the spindle and allows sliding movement of the load plate relative to the bellows. The carrier, load transfer plate and the polishing table may all be made of rigid foam material, such as metal or ceramic, in order to reduce the mass and weight of these elements while providing them with a strong rigid construction.

-

Unengraved Metering Roll Of Porous Ceramic

view source -

US Patent:49676636, Nov 6, 1990

-

Filed:Oct 24, 1988

-

Appl. No.:7/261342

-

Inventors:Robert L. Metcalf - Beaverton OR

-

Assignee:Coors Porcelain Company - Golden CO

-

International Classification:B41F 146

-

US Classification:101348

-

Abstract:An unengraved metering roll made of porous ceramic material is described for depositing measured amounts of liquid as a coating on a substrate such as a metal can. The coating liquid is contained within the pores of the ceramic roll and deposited upon the object or a transfer roll without the use of metering cells which are ordinarily provided by engraving a pattern on the outer surface of the roll. The pores are of a substantially uniform size and are distributed substantially uniformly throughout the ceramic roll. The metering roll of porous ceramic material may be more easily resurfaced merely by grinding in a conventional manner to remove the original outer surface and replacing it with a new outer surface having pores which open to such outer surface for receipt of the coating liquid. The size of the pores and the amount of such pores in the ceramic body are controlled by mixing organic filler particles with the ceramic base material before firing so that such organic particles are burned out during heating of the molded roll body prior to sintering of the ceramic particles to form the porous ceramic roll. In this manner, the size and distribution of the particles can be controlled to match the characteristics of the coating liquid for which the roll is to be used.

License Records

Robert Jefferson Metcalf

License #:

CGC1510014 - Active

Category:

Construction Industry

Issued Date:

Oct 28, 2005

Effective Date:

Sep 8, 2010

Expiration Date:

Aug 31, 2018

Type:

Certified General Contractor

Organization:

METCALF CONSTRUCTION INC

Robert Stephen Metcalf

License #:

CCC1330968 - Active

Category:

Construction Industry

Issued Date:

Apr 27, 2016

Effective Date:

Apr 27, 2016

Expiration Date:

Aug 31, 2018

Type:

Certified Roofing Contractor

Organization:

METRO DESIGN-BUILD, INC

Resumes

Owner And Operator

view sourceLocation:

Portland, OR

Industry:

Luxury Goods & Jewelry

Work:

Metcalf Music & Time

Owner and Operator

Owner and Operator

Education:

Some College

Watch Repair/Restoration, Some College

Watch Repair/Restoration, Some College

Skills:

Watch Repair/Restoration

Customer Service

Music Production

Social Media

Music

Teaching

Songwriting

Marketing

Social Networking

Social Media Marketing

Microsoft Excel

Photoshop

Editing

Composing Music

Customer Service

Music Production

Social Media

Music

Teaching

Songwriting

Marketing

Social Networking

Social Media Marketing

Microsoft Excel

Photoshop

Editing

Composing Music

Robert Metcalf

view source

Robert Metcalf

view source

Robert Metcalf

view sourceSkills:

Teaching

Photoshop

Microsoft Office

Microsoft Word

Powerpoint

Research

Microsoft Excel

English

Customer Service

Windows

Photoshop

Microsoft Office

Microsoft Word

Powerpoint

Research

Microsoft Excel

English

Customer Service

Windows

Robert Metcalf

view sourceLocation:

United States

Robert Metcalf

view sourceLocation:

United States

Robert Metcalf

view sourceLocation:

United States

Robert Metcalf

view sourceLocation:

United States

Medicine Doctors

Robert Paul Metcalf

view sourceSpecialties:

General Practice

Nuclear Medicine

Radiology

Diagnostic Radiology

Nuclear Radiology

Nuclear Medicine

Radiology

Diagnostic Radiology

Nuclear Radiology

Education:

University of Oklahoma(1964)

Plaxo

Robert Metcalf

view sourceVescom

Robert Metcalf

view sourceNC Army National Guard

Classmates

Robert Metcalf

view sourceSchools:

Chester High School Chester VT 1958-1962

Community:

Larry Moffitt, Robert Balch

Robert Metcalf

view sourceSchools:

Lee Academy Clarksdale MS 1968-1972

Community:

Garrett Krug, Bryan Battenfield, Robin Williams

Robert Metcalf

view sourceSchools:

Bryan High School Yellow Springs OH 1947-1951

Community:

Judyth Scaggs, Caroline Loe

Robert Metcalf

view sourceSchools:

Clinton High School Clinton TN 1963-1967

Community:

Betty Pounders, Sandy Lafever

Robert Metcalf

view sourceSchools:

St. Xavier High School Louisville KY 1955-1959

Community:

Bettyjoe Roberts, Linda Metzger, Irene Destefano, Rich Bacon, Peggy Stone

Robert Metcalf

view sourceSchools:

Ss. Katherine & Mark High School Bettendorf IA 1995-1999

Community:

Mark Hall, Mark Hess, Holly Mcdonald

Robert Metcalf

view sourceSchools:

Boston Technical High School Boston MA 1970-1974

Robert Metcalf

view sourceSchools:

Sierra Vista High School Baldwin Park CA 1972-1976

Community:

Kathleen Livingston, Benny Esparza, Jackie Fuentes

Robert Metcalf Sr.

view source

Robert L Metcalf

view source

Robert Metcalf Jr

view source

Robert Metcalf

view source

Robert Metcalf

view source

Robert Metcalf Jr

view source

Robert Metcalf

view source

Robert Metcalf

view sourceGoogleplus

Robert Metcalf

Education:

University of Wollongong - Engineering

Tagline:

"livin life in the fast lane"

Robert Metcalf

Education:

California Institute of Technology - Mechanical Engineering

Robert Metcalf

Work:

Home sweet home - Owner/Operator (2006)

Robert Metcalf

Education:

University of South Alabama - Nursing

Robert Metcalf

Robert Metcalf

Robert Metcalf

Robert Metcalf

Youtube

Myspace

Robert Metcalf

view sourceLocality:

South Pasadena Adjacent, California

Gender:

Male

Birthday:

1939

Flickr

Get Report for Robert F Metcalf from Salem, OR, age ~75