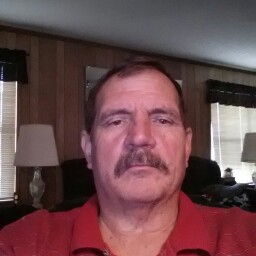

Ronald Dean Key

age ~67

from Broken Arrow, OK

- Also known as:

-

- Ronald D Key

- Ron Kee

- Phone and address:

-

3709 S Willow Ave, Broken Arrow, OK 74011

9188081084

Ronald Key Phones & Addresses

- 3709 S Willow Ave, Broken Arrow, OK 74011 • 9188081084

- 1824 15Th St, Broken Arrow, OK 74012 • 9183551386

- Tulsa, OK

Work

-

Position:Executive, Administrative, and Managerial Occupations

Education

-

Degree:Associate degree or higher

Us Patents

-

Apparatus For Crecovery

view source -

US Patent:7544272, Jun 9, 2009

-

Filed:Aug 16, 2001

-

Appl. No.:09/931218

-

Inventors:Ronald D. Key - Tulsa OK, US

William G. Brown - Tulsa OK, US -

Assignee:Linde Process Plants, Inc. - Tulsa OK

-

International Classification:B01D 3/00

-

US Classification:202 82, 202154

-

Abstract:An improved process for separating a hydrocarbon bearing feed gas containing methane and lighter, C(ethylene and/or ethane), and heavier components into a fraction containing predominantly methane and lighter components and a fraction containing predominantly Cand heavier hydrocarbon components including the steps of cooling and partially condensing and delivering the feed stream to a separator to provide a first residue vapor and a first liquid containing C, directing a first part of the first liquid containing Cinto a heavy-ends fractionation column wherein the liquid is separated into a second hydrocarbon bearing vapor residue and a second liquid product containing C; further cooling the second part of the first liquid containing Cand partially condensing the second hydrocarbon bearing vapor residue; combining the cooled second part of the first liquid and partially condensed second hydrocarbon-bearing vapor residue and directing them to a second separator effecting a third residue and a third liquid; cooling and directing a first part of the third liquid into the lights-ends fractionation column, to thereby condense C's and heavier components while the methane is evaporated in the light-ends fractionation column to thereby obtain fourth residue vapor and liquid, heating and supplying the fourth liquid recovered from the light-ends fractionation column to the heavy-ends fractionation column as a feed thereto; conducting the second part of the third liquid to the heavy-ends fractionation column as a feed thereto.

-

Process And Apparatus For Synthesis Gas Heat Exchange System

view source -

US Patent:7871449, Jan 18, 2011

-

Filed:Jan 31, 2006

-

Appl. No.:11/342705

-

Inventors:Ronald Dean Key - Broken Arrow OK, US

Maqsudur Rahman Khan - Broken Arrow OK, US -

Assignee:Linde Process Plants, Inc. - Tulsa OK

-

International Classification:F28D 7/10

-

US Classification:48 61, 165140, 165138, 165157, 422146

-

Abstract:The invention provides an improved process and apparatus for integrating the heat transfer zones of spiral-wound, plate fin, tube and finned tube exchangers thus increasing the overall effectiveness of the process.

-

Process And Apparatus For Crecovery

view source -

US Patent:8093440, Jan 10, 2012

-

Filed:Jun 4, 2009

-

Appl. No.:12/478066

-

Inventors:Ronald D. Key - Tulsa OK, US

William G. Brown - Tulsa OK, US -

Assignee:Linde Process Plants, Inc. - Tulsa OK

-

International Classification:C10G 7/00

-

US Classification:585800, 585802, 208348, 208349, 208351, 208354, 208355, 208356

-

Abstract:An improved process for separating a hydrocarbon bearing feed gas containing methane and lighter, C(ethylene and/or ethane), and heavier components into a fraction containing predominantly methane and lighter components and a fraction containing predominantly Cand heavier hydrocarbon components including the steps of cooling and partially condensing and delivering the feed stream to a separator to provide a first residue vapor and a first liquid containing C, directing a first part of the first liquid containing Cinto a heavy-ends fractionation column wherein the liquid is separated into a second hydrocarbon bearing vapor residue and a second liquid product containing C; further cooling the second part of the first liquid containing Cand partially condensing the second hydrocarbon bearing vapor residue; combining the cooled second part of the first liquid and partially condensed second hydrocarbon-bearing vapor residue and directing them to a second separator effecting a third residue and a third liquid; cooling and directing a first part of the third liquid into the lights-ends fractionation column, to thereby condense C's and heavier components while the methane is evaporated in the light-ends fractionation column to thereby obtain fourth residue vapor and liquid, heating and supplying the fourth liquid recovered from the light-ends fractionation column to the heavy-ends fractionation column as a feed thereto; conducting the second part of the third liquid to the heavy-ends fractionation column as a feed thereto.

-

Process And Apparatus For Synthesis Gas Heat Exchange System

view source -

US Patent:20120018126, Jan 26, 2012

-

Filed:Jan 14, 2011

-

Appl. No.:13/006712

-

Inventors:Ronald Dean Key - Broken Arrow OK, US

Maqsudur Rahman Khan - Broken Arrow OK, US -

International Classification:F28D 15/00

-

US Classification:16510414

-

Abstract:The invention provides an improved process and apparatus for integrating the heat transfer zones of spiral-wound, plate fin, tube and finned tube exchangers thus increasing the overall effectiveness of the process.

-

Methods For Separating Hydrocarbon Gases

view source -

US Patent:20140013796, Jan 16, 2014

-

Filed:Jul 12, 2012

-

Appl. No.:13/547153

-

Inventors:Zaheer I. Malik - Tulsa OK, US

Ronald D. Key - Broken Arrow OK, US -

International Classification:F25J 3/02

-

US Classification:62620

-

Abstract:A process for separating a hydrocarbon gas into a fraction containing a predominant portion of the methane or ethane and lighter components and a fraction containing a predominant portion of the C2 or C3 and heavier components in which the feed gas is treated in one or more heat exchange and expansion steps; partly condensed feed gas is directed into a separator wherein a first residue vapor is separated from a C2 or C3-containing liquid; and C2 or C3-containing liquids at substantially the pressure of separation are directed into a distillation column wherein the liquid is separated into a second residue to recover a C2 or C3-containing product. A portion of the vapor and/or a portion of the liquid from the first hydrocarbon vapor/liquid separation is further cooled and introduced into a fractionation column to increase the C2 or C3 and heavier hydrocarbons recovery from the natural gas stream.

-

Process For C.sub.2 Recovery

view source -

US Patent:48955841, Jan 23, 1990

-

Filed:Jan 12, 1989

-

Appl. No.:7/296432

-

Inventors:Loren L. Buck - Tulsa OK

Ronald D. Key - Broken Arrow OK -

Assignee:Pro-Quip Corporation - Ponca City OK

-

International Classification:F25J 302

-

US Classification:62 29

-

Abstract:An improved process for separating a hydrocarbon bearing feed gas containing methane and lighter, C. sub. 2 (ethylene and ethane) and heavier components into a fraction containing predominantly methane and lighter components and a fraction containing predominantly C. sub. 2 and heavier hydrocarbon components including the steps of cooling and partially condensing and delivering the feed stream to a separator to provide a first residue vapor and a C. sub. 2 containing liquid, directing a portion of the C. sub. 2 containing liquid into a heavy ends fractionation column wherein the liquid is separated into a second hydrocarbon bearing vapor residue and a C. sub. 2 containing product, conducting a portion of the first residue vapors with at least part of the partially condensed second residue into a light ends fractionating column to thereby obtain third residue vapors and liquids, supplying the liquids recovered from the light ends fractionating column to the heavy ends fractionation column as the liquid feed thereto and directing part of the C. sub. 2 containing liquid from the first step into intimate contact with the second residue, which liquid provides additional liquefied methane which acts with the partially condensed second residue as a direct contact refrigerant to thereby condense C. sub. 2 and heavier components while the methane itself is evaporated in the light ends fractionation column.

-

Process For C2 Recovery

view source -

US Patent:62780352, Aug 21, 2001

-

Filed:Mar 17, 2000

-

Appl. No.:9/527175

-

Inventors:Ronald D. Key - Tulsa OK

William G. Brown - Tulsa OK -

International Classification:C07C 700

C10G 300

B01D 300 -

US Classification:585800

-

Abstract:An improved process for separating a hydrocarbon bearing feed gas containing methane and lighter, C. sub. 2 (ethylene and/or ethane), and heavier components into a fraction containing predominantly methane and lighter components and a fraction containing predominantly C. sub. 2 and heavier hydrocarbon components including the steps of cooling and partially condensing and delivering the feed stream to a separator to provide a first residue vapor and a first liquid containing C. sub. 2, directing a first part of the first liquid containing C. sub. 2 into a heavy-ends fractionation column wherein the liquid is separated into a second hydrocarbon bearing vapor residue and a second liquid product containing C. sub. 2 ; further cooling the second part of the first liquid containing C. sub. 2 and partially condensing the second hydrocarbon bearing vapor residue; combining the cooled second part of the first liquid and partially condensed second hydrocarbon-bearing vapor residue and directing them to a second separator effecting a third residue and a third liquid; cooling and directing a first part of the third liquid into the lights-ends fractionation column, to thereby condense C. sub.

-

Process And Apparatus For C3 Recovery

view source -

US Patent:63115166, Nov 6, 2001

-

Filed:Jan 27, 2000

-

Appl. No.:9/492189

-

Inventors:Ronald D. Key - Tulsa OK

Steven C. Brantingham - Tulsa OK -

International Classification:F25J 300

-

US Classification:62619

-

Abstract:An improved process for separating a hydrocarbon bearing feed gas containing methane and lighter, C. sub. 2 (ethylene and/or ethane), C. sub. 3 (propylene and/or propane) and heavier components into a fraction containing predominantly C. sub. 2 and lighter components and a fraction containing predominantly C. sub. 3 and heavier hydrocarbon components including the steps of cooling and partially condensing and delivering the feed stream to a separator to provide a first residue vapor and a C. sub. 3 containing liquid, directing a portion of the C. sub. 3 containing liquid into a heavy-ends fractionation column wherein the liquid is separated into a second hydrocarbon bearing vapor residue, a second C. sub. 2 containing liquid stream, and a C. sub. 3 containing product.

License Records

Ronald J Key

License #:

2705141010

Category:

Contractor

Resumes

Vice President - Technology And Sales At Linde Process Plants

view sourceLocation:

Tulsa, Oklahoma Area

Industry:

Oil & Energy

Ronald Key

view source

Ronald Key

view source

Ronald Key

view source

Ronald Key

view sourceLocation:

United States

Ronald Key

view sourceLocation:

United States

Flickr

Youtube

Classmates

Ronald Key

view sourceSchools:

Dunean School Greenville SC 1960-1967, Tanglewood Middle School Greenville SC 1967-1968

Community:

Robert Rocha, Steve Williams, Janice Ballew, Rick Hollifield, Susie Culberson

Ronald Key

view sourceSchools:

Robbinsville Middle School Robbinsville NC 1962-1966

Community:

Linda Cook, William Hill, Mary Brown, Gwenda Hooper

Ronald Key

view sourceSchools:

Robbinsville Elementary School Robbinsville NC 1961-1965

Community:

Holly Hampton, Mary Holloway, Tammy Odom, Ruth Robinson, Brandy Moore, Phyllis Moody, Heather Millsaps, Gary Farley, Mary Underwood, Laura Higdon, Edith Hensley

Ronald Key, Sumner High S...

view source

Ronald Key, Dora High Sch...

view source

Hardin High School, Hardi...

view sourceGraduates:

Ronald Key (1956-1960),

kenneth nolen (1962-1966)

kenneth nolen (1962-1966)

Ronald Key

view source

Ronald Key

view source

Ronald Key

view sourceGoogleplus

Ronald Key

Ronald Key

Ronald Key

Education:

UNCC

Myspace

Get Report for Ronald Dean Key from Broken Arrow, OK, age ~67