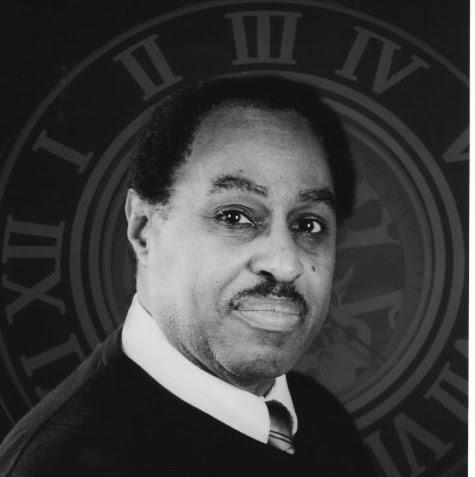

Ronald J Mallet

Deceased

from Minden, LA

- Also known as:

-

- Ronald James Mallet

- Phone and address:

-

338 Tanglewood Dr, Minden, LA 71055

3183773592

Ronald Mallet Phones & Addresses

- 338 Tanglewood Dr, Minden, LA 71055 • 3183773592 • 3183829154

- Irving, TX

- Jennings, LA

- 731 Ledoux St, Jennings, LA 70546 • 3372887515

Work

-

Position:Technicians and Related Support Occupations

Education

-

Degree:Associate degree or higher

Us Patents

-

Pipe Testing Apparatus

view source -

US Patent:6430990, Aug 13, 2002

-

Filed:Nov 10, 2000

-

Appl. No.:09/709861

-

Inventors:Ronald James Mallet - Kaplan LA

-

Assignee:Ronald J. Mallet - Kaplan LA

Kenneth Ray Mallet - Kaplan LA

P. Warren Trahan - Lafayette LA

Fred B. Trahan - Jennings LA -

International Classification:G01M 304

-

US Classification:73 495, 73 407

-

Abstract:An apparatus for forming a test chamber within a tubular and internally pressure testing the tubular with a test gas. The apparatus is comprised of a generally cylindrical tester body having first and second spaced-apart sealing assemblies that are expandable against the inner wall of the tubular by a piston assembly so as to form a test chamber defined by the inner wall of the tubular and the expanded seal assemblies. The pistons of the first sealing assembly are gas actuated pistons acting in cooperation with the seals of the first sealing assembly in response to a gas under pressure. The pistons of the second sealing assembly are fluid actuated pistons acting in cooperation with the seals of the second sealing assembly in response to a fluid under pressure. The pressure of the gas and the pressure of the fluid used to actuate the first and second pistons are controlled independently of each other. The gas used to activate the first set of pistons is directed to the test chamber to serve as a test gas.

-

Appparatus For Pressure Testing Of Tubulars

view source -

US Patent:55633366, Oct 8, 1996

-

Filed:Sep 13, 1995

-

Appl. No.:8/527742

-

Inventors:Ronald J. Mallet - Rayne LA

-

International Classification:G01M 308

-

US Classification:73 491

-

Abstract:An apparatus for pressure testing of tubulars. The apparatus comprises a tester body having multiple spaced-apart external circumferential seal elements expansible by piston movement; a seal gas saver valve connected to the tester body; and a pressurized seal and test gas source to supply gas to the tester. The tester body is inserted into a tubular so that the seal elements are astride a desired test area, typically a tubular connection. Seal gas pressure is then applied to move the pistons and expand the seal elements against the tubular wall, forming a test chamber. Test gas is then introduced into the chamber to achieve a desired pressure, and external containment and sensing means are used to detect any escape of test gas, thereby showing a leak. When the test is complete, the test gas pressure is released, and the seal gas pressure is reduced, with the seal gas flowing back into a reclamation tank. When a desired seal gas retention pressure is reached, the seal gas saver valve closes, maintaining the pressure in the seal gas supply line and venting the small remaining seal gas volume in the tester body.

Classmates

Ronald Mallet

view sourceSchools:

Austin High School Port Arthur TX 1963-1967

Community:

Jerry Bodin, John Brocks, Ben Morris, Michelle Simmons

Steven F. Austin High Sch...

view sourceGraduates:

Ronald White (1998-2002),

Patricia Ratley (1996-2000),

Ronald Mallet (1963-1967),

Donna Gaspard (1974-1978)

Patricia Ratley (1996-2000),

Ronald Mallet (1963-1967),

Donna Gaspard (1974-1978)

Flickr

Myspace

Ronald Mallet

view sourceBirthday:

1923

Youtube

Googleplus

Ronald Mallet

Ronald Mallet

Get Report for Ronald J Mallet from Minden, LADeceased