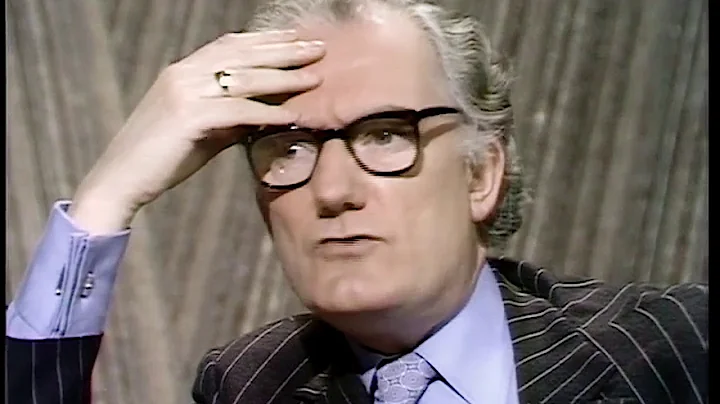

Ronald Leroy Mcghee

age ~54

from Lynnwood, WA

- Also known as:

-

- Ronald L Mcghee

- Ronald L Mcgee

- Ron Mcghee

Ronald Mcghee Phones & Addresses

- Lynnwood, WA

- Orondo, WA

- 7403 Mcdougall Ave, Everett, WA 98203 • 4254238627

- 8407 18Th St, Everett, WA 98204 • 4254238627

- 2007 Jackson Ave, Everett, WA 98203 • 4254238627

- 6028 Kenwood Dr, Everett, WA 98203 • 4254238627

- Washington Township, OH

- Douglas, WA

- Pullman, WA

- Redmond, WA

- Renton, WA

Us Patents

-

Fuselage Structure Splice

view source -

US Patent:20210261230, Aug 26, 2021

-

Filed:Feb 21, 2020

-

Appl. No.:16/798187

-

Inventors:- Chicago IL, US

Ronald Leroy McGhee - Lynnwood WA, US -

Assignee:The Boeing Company - Chicago IL

-

International Classification:B64C 1/06

B64F 5/10 -

Abstract:A fuselage structure splice may include a panel having an edge and a strap connected to the first panel along the panel edge. A strap surface not in contact with the panel tapers toward the panel with distance from the panel edge. A stringer is mounted on the panel and extends away from the edge of the panel and has a flange mounted to the panel. A fitting has a stringer base portion and a strap base portion. The stringer base portion is connected to the stringer flange and extends along a first line extending in a plane normal to the panel edge. The strap base portion of the fitting is mounted on the strap surface and extends along a second line in the plane. The second line is transverse to the first line and the strap base portion of the fitting has a constant thickness along the second line.

-

Method For Manufacturing A Composite Structure Using A Layup Of Net-Trimmed Plies Having A Staggered Edge Structure

view source -

US Patent:20210016524, Jan 21, 2021

-

Filed:Jul 16, 2019

-

Appl. No.:16/513027

-

Inventors:- Chicago IL, US

Ronald L. McGhee - Lynnwood WA, US

Devin A. Good - Snohomish WA, US

Wade A. Oswald - Mukilteo WA, US -

Assignee:The Boeing Company - Chicago IL

-

International Classification:B29C 70/54

B32B 3/26

B29C 70/30

B32B 27/08 -

Abstract:A method for manufacturing a composite structure. The method includes trimming plies of composite material to a near net-shape, thereby yielding a plurality of net-trimmed plies, wherein each net-trimmed ply of the plurality of net-trimmed plies includes an edge. The method further includes assembling a layup that includes the plurality of net-trimmed plies, wherein the assembling of the layup includes staggering the edges of the plurality of net-trimmed plies such that the edges define a staggered edge structure. The method further includes pressing the layup to form the staggered edge structure into a bevel.

-

Method For Co-Curing Perpendicular Stiffeners

view source -

US Patent:20190381700, Dec 19, 2019

-

Filed:Jun 18, 2018

-

Appl. No.:16/010905

-

Inventors:- Chicago IL, US

Eileen E. Miller - Summerville SC, US

Mark Allen Ulvin - Brier WA, US

Ronald Leroy McGhee - Lynnwood WA, US

David A. Lilienthal - Summerville SC, US -

International Classification:B29C 35/02

B32B 3/08

B32B 7/08

B32B 27/08

B29C 70/54

B32B 7/12 -

Abstract:A method for fabricating a composite structure is provided. A first number of layers of composite material is laid up to form a first set of stiffeners. A second number of layers of composite material is laid up to form a panel. The first set of stiffeners is associated with a first side of the panel. A pre-cured composite strip is positioned on a second side of the panel, opposite the first side. A third number of layers of composite material is laid up on the second side of the panel to form a second set of stiffeners running perpendicular to the first set of stiffeners. The pre-cured composite lies at an intersection between one of the first set of stiffeners and one of the second set of stiffeners. All the layers of composite material are co-cured to form the composite structure.

Name / Title

Company / Classification

Phones & Addresses

JUDAH BIBLE MINISTRIES

Resumes

Ronald Mcghee

view source

Ronald Man Mcghee

view source

Ronald Mcghee

view sourceYoutube

Googleplus

Ronald Mcghee

Flickr

Ronald Red Mcghee

view sourceMyspace

Ronald McGhee

view source

ronald mcghee

view sourceClassmates

Ronald McGhee

view sourceSchools:

Atkins Elementary School Atkins VA 1955-1962, Marion Middle School Marion VA 1962-1963

Ronald McGhee

view sourceSchools:

Wendell Smith Elementary School Chicago IL 1974-1981

Community:

Karen Hotchkiss, Marlon Hall

Ronald McGhee, Jellico Hi...

view source

Ronald McGhee | Southern ...

view source

Ronald McGhee,sr | Capito...

view source

Ron McGhee, Dexter High S...

view source

Ron McGhee | Oak Park Riv...

view source

Atkins Elementary School,...

view sourceGraduates:

Ashley Malchano (1997-2001),

Sarah Morgan (1974-1978),

Patricia Hamby (1962-1969),

Ronald McGhee (1955-1962)

Sarah Morgan (1974-1978),

Patricia Hamby (1962-1969),

Ronald McGhee (1955-1962)

Get Report for Ronald Leroy Mcghee from Lynnwood, WA, age ~54