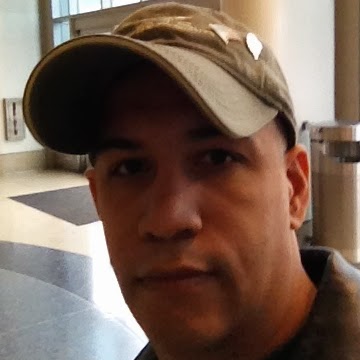

Ronald D Reece

age ~63

from Fairfield, OH

- Also known as:

-

- Ronald L Reece

- Ron D Reece

- Ron L Reece

- Ronald D Reese

- Paul Grabel

- Phone and address:

-

3844 River Rd, Hamilton, OH 45015

5138631876

Ronald Reece Phones & Addresses

- 3844 River Rd, Hamilton, OH 45015 • 5138631876

- Fairfield, OH

- Danvers, MA

- Atlanta, GA

- Painesville, OH

Us Patents

-

Systems And Methods That Mitigate Contamination And Modify Surface Characteristics During Ion Implantation Processes Through The Introduction Of Gases

view source -

US Patent:7511287, Mar 31, 2009

-

Filed:Nov 14, 2005

-

Appl. No.:11/273039

-

Inventors:Ronald N. Reece - Westwood MA, US

Serguei I. Kondratenko - Swampscott MA, US

Geumjoo Ra - North Andover MA, US

Louis P. Wainwright - Beverly MA, US

Gary N. Cai - Beverly MA, US -

Assignee:Axcelis Technologies, Inc. - Beverly MA

-

International Classification:H01J 37/36

-

US Classification:2504922, 25049221

-

Abstract:A contamination mitigation or surface modification system for ion implantation processes includes a gas source, a controller, a valve, and a process chamber. The gas source provides delivery of a gas, be it atmospheric or reactive, to the valve and is controlled by the controller. The valve is located on or about the process chamber and controllably adjusts flow rate and/or composition of the gas to the process chamber. The process chamber holds a target device, such as a target wafer and permits interaction of the gas with an ion beam to mitigate contamination of the target wafer and/or to modify the existing properties of the processing environment or target device to change a physical or chemical state or characteristic thereof. The controller selects and adjusts composition of the gas and flow rate according to contaminants present within the ion beam, or lack thereof, as well total or partial pressure analysis.

-

Ion Beam Incident Angle Detector For Ion Implant Systems

view source -

US Patent:20040195528, Oct 7, 2004

-

Filed:Apr 1, 2003

-

Appl. No.:10/404493

-

Inventors:Ronald Reece - Westwood MA, US

Michael Graf - Cambridge MA, US

Thomas Parrill - North Andover MA, US

Brian Freer - Medford MA, US -

International Classification:H01J037/317

H01J037/244 -

US Classification:250/492210, 250/397000

-

Abstract:The present invention facilitates semiconductor device fabrication by monitoring and correcting angular errors during ion implantation procedures via an incident ion beam angle detector. Additionally, the present invention facilitates semiconductor device fabrication by calibrating a process disk with respect to an incident ion beam without measuring implantation results on wafers prior to an ion implantation process.

-

In-Situ Wafer Temperature Measurement And Control

view source -

US Patent:20190304820, Oct 3, 2019

-

Filed:Mar 28, 2019

-

Appl. No.:16/367948

-

Inventors:- Beverly MA, US

Ronald N. Reece - Westwood MA, US

Petros Miltiades Kopalidis - Swampscott MA, US -

International Classification:H01L 21/67

H01L 21/683

H01L 21/687

H01J 37/317

H01J 37/20 -

Abstract:A thermal chuck selectively retains a workpiece on a clamping surface. The thermal chuck has one or more heaters to selectively heat the clamping surface and the workpiece. A thermal monitoring device determines a temperature of a surface of the workpiece when the workpiece resides on the clamping surface, defining one or more measured temperatures. A controller selectively energizes the one or more heaters based on the one or more measured temperatures. The thermal monitoring device may be one or more of a thermocouple or RTD in selective contact with the surface of the workpiece and an emissivity sensor or pyrometer not in contact with the surface. The thermal chuck can be part of an ion implantation system configured to implant ions into the workpiece. The controller can be further configured to control the heaters based on the measured temperatures.

Vehicle Records

-

Ronald Reece

view source -

Address:5480 Ponderosa Dr, Fairfield, OH 45014

-

Phone:5136427390

-

VIN:1G1ZH57B984248748

-

Make:CHEVROLET

-

Model:MALIBU

-

Year:2008

-

Ronald Reece

view source -

Address:13 Hurst Rd, Painesville, OH 44077

-

Phone:4403549771

-

VIN:5J6RE48367L002000

-

Make:HONDA

-

Model:CR-V

-

Year:2007

Resumes

Ronald Reece

view sourceName / Title

Company / Classification

Phones & Addresses

ANTWERP COMMUNITY BAND, INC

Treasurer

WESTWOOD COMMUNITY PLAYGROUND, INC

138 Church St, Westwood, MA 02090

Medicine Doctors

Ronald E. Reece

view sourceSpecialties:

Dermatology

Work:

Ronald E Reece MD

2701 Old Eureka Way STE 2A, Redding, CA 96001

5302460236 (phone), 5302460276 (fax)

2701 Old Eureka Way STE 2A, Redding, CA 96001

5302460236 (phone), 5302460276 (fax)

Education:

Medical School

Loma Linda University School of Medicine

Graduated: 1980

Loma Linda University School of Medicine

Graduated: 1980

Procedures:

Destruction of Benign/Premalignant Skin Lesions

Skin Surgery

Destruction of Skin Lesions

Skin Tags Removal

Skin Surgery

Destruction of Skin Lesions

Skin Tags Removal

Conditions:

Acne

Alopecia Areata

Atopic Dermatitis

Contact Dermatitis

Dermatitis

Alopecia Areata

Atopic Dermatitis

Contact Dermatitis

Dermatitis

Languages:

English

Description:

Dr. Reece graduated from the Loma Linda University School of Medicine in 1980. He works in Redding, CA and specializes in Dermatology. Dr. Reece is affiliated with Shasta Regional Medical Center.

Ronald Reece

view source

Ronald Reece

view source

Ronald Reece

view source

Ronald Reece

view source

Ronald Reece

view sourceMyspace

Googleplus

Ronald Reece

Work:

27 jobs since 14 years of age

About:

Ex raf , electronics distribution, recruitment, retired. Interested in n number of things

Ronald Reece

Ronald Reece

Ronald Reece

Ronald Reece

Flickr

Youtube

Classmates

Ronald Reece

view sourceSchools:

Peteetneet Elementary School Payson UT 1947-1949, Payson Adult High School Payson UT 1956-1959

Community:

Sherrie Fleenor, Karen Kennedy, Vickie Buckwalter

Ronald Reece

view sourceSchools:

Bluff City High School Bluff City TN 1961-1965

Community:

June Mcgaha

Ronald Reece

view sourceSchools:

Buena Vista High School Saginaw MI 1987-1991

Community:

Kelly Findlay

Ronald Reece

view sourceSchools:

Antwerp High School Antwerp OH 1975-1979

Community:

Jerry Conner, Micki Speer

Ronald Reece

view sourceSchools:

Longfellow Elementary School St. Louis MO 1944-1948

Community:

Mark Grisham, Michael Largent, Richard Miller, Richard Whitmore

ronald Reece | North Rose...

view source

Ronald Reece | Union-Endi...

view source

Ron Reece, Lyndon High Sc...

view sourceGet Report for Ronald D Reece from Fairfield, OH, age ~63