Sae Yoon Lee

age ~42

from Irvine, CA

- Also known as:

-

- Sae Y Lee

- Saeyoon Lee

- Shae Y Lee

- Saeyoon Park

Sae Lee Phones & Addresses

- Irvine, CA

- Vernon Hills, IL

- Wheeling, IL

- Fullerton, CA

- Norwalk, CA

Us Patents

-

Means And Method For Manufacture Of A High-Resolution Color Cathode Ray Tube

view source -

US Patent:47130342, Dec 15, 1987

-

Filed:Jul 23, 1985

-

Appl. No.:6/758174

-

Inventors:Sae D. Lee - Buffalo Grove IL

Kazimir Palac - Carpentersville IL -

Assignee:Zenith Electronics Corporation - Glenview IL

-

International Classification:H01J 9227

H01J 940 -

US Classification:445 45

-

Abstract:In-process articles of manufacture are disclosed for the manufacture of a high-resolution color cathode ray tube having a tensed foil shadow mask. A first article-in-process comprises a faceplate with a target area for receiving at least one pattern of phosphor deposits. The faceplate has attached at preselected, widely spaced locations on the sides thereof a plurality of discrete, detachable first indexing elements. An article-in-process comprises a shadow mask support assembly having a frame ultimately constituting a part of the tube envelope; the frame supports the shadow mask in precise adjacency to the target area. The frame has attached on the sides thereof a like plurality of discrete, detachable second indexing elements which are in facing adjacency to the first indexing elements on the faceplate when the faceplate and frame are mated. Temporary attachment of the indexing elements is by means of a thermally degradable cement. The faceplate and frame can be inter-registered in precise relationship by the temporary use of the first and second indexing elements in the process of screening the pattern of phosphor deposits on the target area and later in the final assembly of the tube.

-

Method For The Production Of Optical Waveguides Employing Trench And Fill Techniques

view source -

US Patent:52813053, Jan 25, 1994

-

Filed:May 22, 1992

-

Appl. No.:7/888568

-

Inventors:Sae H. Lee - Fullerton CA

Richard L. Davis - Redondo Beach CA -

Assignee:Northrop Corporation - Los Angeles CA

-

International Classification:H01L 21306

B44C 122 -

US Classification:156657

-

Abstract:A method is described for producing stacked optical waveguides in a silicon dioxide substrate and includes the steps of: etching a first trench in the substrate; filling the first trench with a glassy optical transmission media; depositing a layer of silicon dioxide over the filled trench; etching a second trench in the silicon dioxide layer, the second trench aligned with the first trench; and filling the second trench with a glassy optical transmission media.

-

Cathode Ray Tube Implosion Protection System

view source -

US Patent:47394129, Apr 19, 1988

-

Filed:Aug 8, 1986

-

Appl. No.:6/894984

-

Inventors:Sae D. Lee - Buffalo Grove IL

-

Assignee:Zenith Electronics Corporation - Glenview IL

-

International Classification:H01J 2987

-

US Classification:358247

-

Abstract:A resin bonding system which bonds an implosion protection panel to the faceplate of a CRT tube and is cured by exposure to ultraviolet radiation. The resin bonding system is designed for differential adhesion so that the faceplate separates more easily from the resin than does the implosion protection panel, thus achieving superior implosion performance.

-

Means And Method For Manufacture For A High-Resolution Color Cathode Ray Tube

view source -

US Patent:47907851, Dec 13, 1988

-

Filed:Dec 11, 1987

-

Appl. No.:7/131968

-

Inventors:Sae D. Lee - Buffalo Grove IL

Kazimir Palac - Carpentersville IL -

Assignee:Zenith Electronics Corporation - Glenview IL

-

International Classification:H01J 920

-

US Classification:445 45

-

Abstract:Components-in process and assemblies-in-process are disclosed for use in the manufacture of a high-resolution color cathode ray tube having a tensed foil shadow mask. A first component-in-process comprises a faceplate with a target area for receiving at least one pattern of phosphor deposits. The faceplate has attached at preselected, widely spaced locations on the sides thereof a plurality of discrete, detachable first indexing elements. A second component-in-process comprises a shadow mask support assembly having a frame ultimately constituting a part of the tube envelope; the frame supports the shadow mask in precise adjacency to the target area. The frame has attached on the sides thereof a like plurality of discrete, detachable second indexing elements which are in facing adjacency to the first indexing elements on the faceplate when the faceplate and frame are mated. Temporary attachment of the indexing elements is by means of a thermally degradable cement. The faceplate and frame can be inter-registered in precise relationship by the temporary use of the first and second indexing elements in the process of screening the pattern of phosphor deposits on the target area and later in the final assembly of the tube.

-

Cathode Ray Tube Contrast Enhancement Systems

view source -

US Patent:48413720, Jun 20, 1989

-

Filed:Dec 15, 1986

-

Appl. No.:6/941458

-

Inventors:Sae D. Lee - Buffalo Grove IL

-

Assignee:Zenith Electronics Corporation - Glenview IL

-

International Classification:H01J 2987

-

US Classification:358247

-

Abstract:A resin bonding system which bonds a substantially flat implosion protection panel to the nominally flat faceplate of a flat tension mask CRT tube and is cured by exposure to ultraviolet radiation. The resin bonding system is designed for differential adhesion so that the faceplate separates more easily from the resin than does the implosion protection panel, thus achieving superior implosion performance. It also incorporates a contrast-enhancing neutral density agent, preferably confined to a flat layer adjacent to and adhered to the flat surface of the implosion panel in order to achieve uniform neutral density filtration across the face of the tube. The neutral density agent is preferably an organic dye. Because the nominally flat faceplate is actually somewhat concave after evacuation of the tube, confining the neutral density agent to the layer which adheres to the flat faceplate avoids mottling of the CRT picture which would otherwise result from changes in the thickness of the pigmented layer across the face of the CRT.

-

Flat Tension Mask Cathode Ray Tube Implosion System

view source -

US Patent:49300156, May 29, 1990

-

Filed:Apr 6, 1988

-

Appl. No.:7/178111

-

Inventors:Lawrence W. Dougherty - Sleepy Hollow IL

Sae D. Lee - Buffalo Grove IL

Melvin F. Rogers - Western Springs IL -

Assignee:Zenith Electronics Corporation - Glenview IL

-

International Classification:H04N 565

-

US Classification:358246

-

Abstract:A CRT implosion protection system having a resin system releasably bonding an implosion panel to the faceplate of a flat or concave CRT and a tension band system secured around the periphery of the faceplate which exerts compression thereon. The tension band system includes a pair of keeper bars which prevent the tension band from slipping, and which secure an external magnetic shield to the CRT.

-

Contrast Enhancing Optical Coupling Pad For Projection Tv

view source -

US Patent:46212949, Nov 4, 1986

-

Filed:Mar 30, 1984

-

Appl. No.:6/595085

-

Inventors:Sae D. Lee - Buffalo Grove IL

-

Assignee:Zenith Electronics Corporation - Glenview IL

-

International Classification:H04N 574

-

US Classification:358237

-

Abstract:An image projection system using a projection type cathode ray tube and lens element. The improvement being a direct optical coupling between the display surface and the lens element comprised of a transparent, compressible, multi-layer, resin formulated pad wherein the outer layer of the pad are peelable.

Name / Title

Company / Classification

Phones & Addresses

Owner

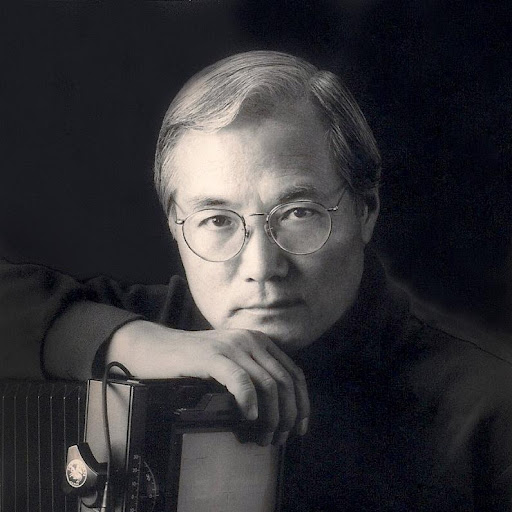

Sae Lee Portrait Gallery

Whol Durable Goods

Whol Durable Goods

8322 Beverly Blvd, Los Angeles, CA 90048

President

NIPPON MOTORS INC

Ret Auto/Home Supplies Whol Auto Parts/Supplies Whol Used Auto Parts · Car Sales

Ret Auto/Home Supplies Whol Auto Parts/Supplies Whol Used Auto Parts · Car Sales

12132 166 St, Cerritos, CA 90703

5624071212, 5624071217

5624071212, 5624071217

President

LG HOUSEHOLD AND HEALTH CARE AMERICA, INC

Whol Drugs/Sundries

Whol Drugs/Sundries

13102 Imperial Hwy, Santa Fe Springs, CA 90670

17777 Ctr Ct Dr N, Artesia, CA 90703

5626538055

17777 Ctr Ct Dr N, Artesia, CA 90703

5626538055

President

OORALLE, INC

Business Services at Non-Commercial Site

Business Services at Non-Commercial Site

331 S Ardmore Ave #216, Los Angeles, CA 90020

1036 S Serrano Ave, Los Angeles, CA 90006

1036 S Serrano Ave, Los Angeles, CA 90006

Director

Father School Mission Center

School/Educational Services

School/Educational Services

616 S Westmoreland Ave, Los Angeles, CA 90005

2133825440

2133825440

Manager

Baskin Robbins

Eating Places

Eating Places

8938 N Greenwood Ave, Niles, IL 60714

8472991666

8472991666

Owner

Wienerschnitzel

Fast-Food Rest Chain · Restaurants

Fast-Food Rest Chain · Restaurants

1951 Hbr Blvd, Costa Mesa, CA 92627

9496315181

9496315181

Manager

Baskin-Robbins

Doughnuts

Doughnuts

7039 W Dempster St, Niles, IL 60714

Resumes

Sae Lee

view sourceLocation:

United States

Owner At Sae Lee Portrait Gallery

view sourcePosition:

owner at sae lee portrait gallery

Location:

Greater Los Angeles Area

Industry:

Photography

Work:

sae lee portrait gallery

owner

owner

Director Of Program Evaluation At Didi Hirsch Community Mental Health Services

view sourcePosition:

Director of Program Evaluation at Didi Hirsch Community Mental Health Services

Location:

Greater Los Angeles Area

Industry:

Research

Work:

Didi Hirsch Community Mental Health Services - Culver City, CA since May 2012

Director of Program Evaluation

Harder+Company Community Research May 2007 - Apr 2012

Research Associate

Evaluation, Management, and Training Associates Apr 2005 - Feb 2007

Research Associate

Los Angeles Unified School District Oct 2000 - Jul 2002

Educational Research Analyst

Director of Program Evaluation

Harder+Company Community Research May 2007 - Apr 2012

Research Associate

Evaluation, Management, and Training Associates Apr 2005 - Feb 2007

Research Associate

Los Angeles Unified School District Oct 2000 - Jul 2002

Educational Research Analyst

Education:

Claremont Graduate University

University of California, Los Angeles

University of California, Los Angeles

Skills:

Program Evaluation

SPSS

Research Design

Qualitative Research

Survey Design

Focus Groups

PowerPoint

Quantitative Research

Survey Methodology

Multivariate Statistics

Community Needs Assessments

Social Network Analysis

Project Management

SPSS

Research Design

Qualitative Research

Survey Design

Focus Groups

PowerPoint

Quantitative Research

Survey Methodology

Multivariate Statistics

Community Needs Assessments

Social Network Analysis

Project Management

Languages:

Korean

Career Counselor At Uc Riverside

view sourceLocation:

Greater Los Angeles Area

Industry:

Higher Education

Lawyers & Attorneys

Sae Hyun Lee - Lawyer

view sourceLicenses:

Texas - Eligible To Practice In Texas 2010

Education:

University of Houston Law Center

Degree - Master of Laws

Graduated - 2012

University of Texas School of Law

Degree - Master of Laws

Graduated - 2012

University of Texas School of Law

Specialties:

Oil - Gas - 100%

Languages:

Korean

Googleplus

Sae Lee

Sae Lee

Tagline:

Beauty, class, and elegance lie within the soul; money, power, and romance are waiting for us all

Sae Lee

Sae Lee

Sae Lee

Sae Lee

Sae Lee

Sae Lee

Youtube

Myspace

Flickr

Classmates

Sae Yeun Lee

view sourceSchools:

Duncan U. Fletcher Middle School Jacksonville Beach FL 1991-1994

Irvington Middle School, ...

view sourceGraduates:

sae Lee (2000-2002),

Allison Gabriel (1981-1984),

Deborah Azerrad (1974-1976),

Peter Bernhardt (1974-1978)

Allison Gabriel (1981-1984),

Deborah Azerrad (1974-1976),

Peter Bernhardt (1974-1978)

Taylor Middle School, Mil...

view sourceGraduates:

Joanne Shweid (1988-1992),

Edward Bowen (1972-1974),

Sae Lee (1990-1991),

Angleica Lee (2000-2004)

Edward Bowen (1972-1974),

Sae Lee (1990-1991),

Angleica Lee (2000-2004)

Sae Young Lee

view source

Sae Yong Lee

view source

Sae Byeol Lee

view source

Sae Kyoul Lee

view source

Sae Byull Lee

view source

Sae Lome Lee

view source

Sae Young Lee

view source

Sae Young Lee

view sourceGet Report for Sae Yoon Lee from Irvine, CA, age ~42

![[Award] MBC 2004 Drama Award Lee Seo Jin [Award] MBC 2004 Drama Award Lee Seo Jin](https://i.ytimg.com/vi/kt60ClP1FRo/0.jpg)