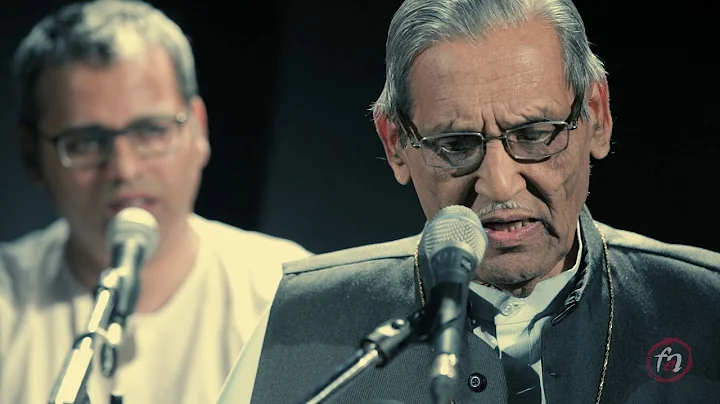

Sharad R Moghe

age ~88

from Cumming, GA

- Also known as:

-

- Sharad Penelope Moghe

Sharad Moghe Phones & Addresses

- Cumming, GA

- Northfield, OH

- 5556 Broadview Rd, Cleveland, OH 44134 • 2163516972 • 2163515893

- Parma, OH

- 603 Stearns Hill Rd, Waltham, MA 02451

- Twinsburg, OH

- Streetsboro, OH

Us Patents

-

Carbon/Carbon Composite Fasteners

view source -

US Patent:51277832, Jul 7, 1992

-

Filed:May 25, 1989

-

Appl. No.:7/356815

-

Inventors:Sharad R. Moghe - Northfield Center OH

Mark J. Purdy - Akron OH

Wei-Teh Shih - Yorba Linda CA

James A. Tallon - Buena Park CA -

Assignee:The B.F. Goodrich Company - Akron OH

-

International Classification:F16B 3504

B65H 8100 -

US Classification:411411

-

Abstract:A carbon and/or ceramic fiber reinforced carbon and/or ceramic matrix composite threaded member including a core, a fiber containing thread-defining element bonded to the exterior of the core and a reinforcing fabric layer securing the thread-defining element to the core. The thread-defining element may be an integral part of a tubular braided reinforcing fabric or applied to the core prior to application of a reinforcing fabric layer. Externally and internally threaded members and methods for their manufacture are described.

-

Fiber Reinforced Composite Threaded Member

view source -

US Patent:51142902, May 19, 1992

-

Filed:Dec 16, 1988

-

Appl. No.:7/285482

-

Inventors:Sharad R. Moghe - Northfield Center OH

-

Assignee:The B. F. Goodrich Company - Akron OH

-

International Classification:F16B 3504

B32B 3100 -

US Classification:411411

-

Abstract:A threaded member including a core, a thread-defining element helically extending around and along the core and a reinforcing tubular fabric layer bonded to the exterior surface of the combined core and thread-defining element. The radial projection of the thread-defining element defines a helical thread whose contour is followed by the fabric layer and the exterior surface of the threaded member. The composite threaded member may be formed by forming a braided or knit fabric layer on an elongated spiral wrapped core. The spiral wrapped thread-defining element and the fabric reinforcing layer is bonded to the core. A polymer sheath protects the underlying structure.

-

Braided Composite Threaded Member

view source -

US Patent:50927272, Mar 3, 1992

-

Filed:Dec 16, 1988

-

Appl. No.:7/285480

-

Inventors:Sharad R. Moghe - Northfield Center OH

-

Assignee:The B. F. Goodrich Company - Akron OH

-

International Classification:F16B 3504

-

US Classification:411411

-

Abstract:A threaded member including a core having an integral tubular braided layer bonded to the exterior surface of the core. The braided layer includes at least one element of greater radial projection which defines a helical thread on the exterior surface of the core. The composite threaded member may be formed by forming a braided layer on an elongated core. The braided layer includes at least one element of greater radial projection relative to the core than the remainder of the elements forming the braided layer. The element of greater radial projection defines a helical thread on the core. The braided layer is bonded to the core.

-

Triaxially Braided Composite Nut And Bolt

view source -

US Patent:50805479, Jan 14, 1992

-

Filed:Mar 30, 1990

-

Appl. No.:7/502375

-

Inventors:Sharad R. Moghe - Northfield Center OH

-

Assignee:The B. F. Goodrich Company - Akron OH

-

International Classification:F16B 3716

-

US Classification:411436

-

Abstract:A hollow composite internally threaded member such as a nut includes a reinforcing fabric layer such as a braided or knit layer extending in the axial direction of the member and conforming to its threads and an exterior cross-sectional configuration defined by a tubular braided triaxial fabric having axially extending elements of greater size than the remainder of the elements forming the triaxial fabric. A method of making such an internally threaded member comprises forming and embedding in a mtrix at least one reinforcing fabric layer and one triaxial fabric layer on an externally threaded cylindrical core and thereafter removing the core. Such internally threaded member may be threadedly joined and bonded to an externally threaded member of complementary thread pitch and thread diameter to form a bolt. The externally threaded member may comprise an elongate core having an integral tubular fabric layer bonded to its exterior surface.

-

Composite Nut And Bolt

view source -

US Patent:50339257, Jul 23, 1991

-

Filed:Dec 16, 1988

-

Appl. No.:7/285483

-

Inventors:Sharad R. Moghe - Northfield Center OH

-

Assignee:The B. F. Goodrich Company - Akron OH

-

International Classification:F16B 3500

F16B 3716 -

US Classification:411366

-

Abstract:A hollow composite internally threaded member such as a nut includes a reinforcing fabric layer such as a braided or knit layer extending in the axial direction of the member and conforming to its threads. A method of making such an internally threaded member comprises forming and embedding in a polymeric matrix a reinforcing fabric layer on an externally threaded cylindrical core and thereafter removing the core. Such internally threaded member may be threadedly joined and adhesively bonded to an externally threaded member of complementary thread pitch and thread diameter to form a bolt. The externally threaded member may comprise an elongate core having an integral tubular fabric layer bonded to its exterior surface.

-

Extruder Strainer Plate

view source -

US Patent:41509323, Apr 24, 1979

-

Filed:Apr 18, 1977

-

Appl. No.:5/788220

-

Inventors:Sharad R. Moghe - Northfield Center OH

-

Assignee:The B. F. Goodrich Company - Akron OH

-

International Classification:B29F 306

-

US Classification:425197

-

Abstract:Aramid fiber reinforced hose having the fiber in discrete particles extruded with the elastomer to provide orientation of the aramid fibers in two oppositely helical overlapping directions. A strainer plate is located within the extruder that has a series of apertures on concentric circles with each series of apertures extending through the plate at opposite helical directions.

-

Composite Structure Attachment System

view source -

US Patent:48185787, Apr 4, 1989

-

Filed:Jan 11, 1988

-

Appl. No.:7/142381

-

Inventors:Sharad R. Moghe - Northfield Center OH

-

Assignee:The B. F. Goodrich Company - Akron OH

-

International Classification:B32B 300

-

US Classification:428 57

-

Abstract:A load-bearing member is positioned in a slot extending through a composite structure of laminated reinforced plastic having overlapping layers of fabric plies embedded in a thermoplastic material. A connecting means such as a shank of a bolt connects the load-bearing member with a second structure. The load-bearing member has a flat surface engageable with a flat surface of the slot which is generally parallel with the edge surface of the composite structure in abutting relationship with a surface of the second structure. The slot extends through the overlapping layers of fabric plies in such a manner that the load is distributed by the load-bearing member to avoid the concentration of forces which cause shear failure and delamination.

Youtube

Get Report for Sharad R Moghe from Cumming, GA, age ~88