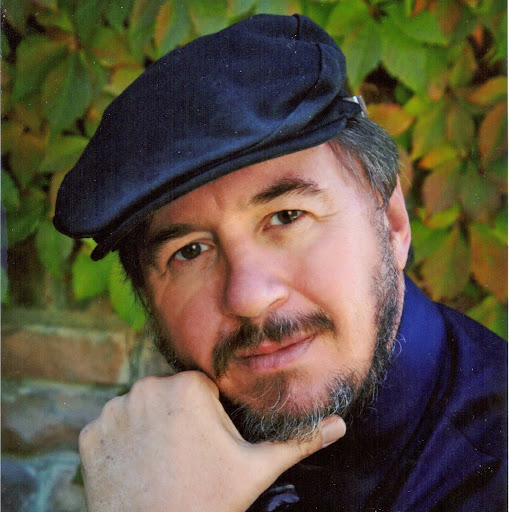

Stephen M Day

age ~86

from Tipp City, OH

- Also known as:

-

- Stephen Michael Day

- Stephen M Way

- Steve M Day

Stephen Day Phones & Addresses

- Tipp City, OH

- Fort Worth, TX

- Piqua, OH

- Dayton, OH

- 731 Cheyenne Pl, Tipp City, OH 45371 • 9376237703

Work

-

Position:Protective Service Occupations

Us Patents

-

Fiber Reinforced Composite Cores And Panels

view source -

US Patent:6740381, May 25, 2004

-

Filed:Dec 27, 2000

-

Appl. No.:09/749064

-

Inventors:Stephen W. Day - Dayton OH

Daniel M. Hutcheson - Bellbrook OH

G. Scott Campbell - Dayton OH -

Assignee:Webcore Technologies, Inc. - Centerville OH

-

International Classification:B32B 310

-

US Classification:428 56, 4283166, 4283099, 4283179, 428 86, 428 74, 4283186, 527821, 527901, 527941

-

Abstract:A fiber reinforced core is formed from plastics foam material having elongated porous and fibrous webs and/or rovings extending through the foam material. The rovings may extend angularly through the webs, and strips of the foam material may be helically wound with layers of crossing rovings to form the webs. Porous and fibrous skins for the core may be formed by the wound rovings and by parallel continuous rovings, and the foam strips may be formed with internal grooves adjacent the webs and connected by a feeder channel for infusing a hardenable adhesive resin into the grooves and outwardly through the webs to the skins with differential pressure on the resin.

-

Fiber Reinforced Composite Cores And Panels

view source -

US Patent:7393577, Jul 1, 2008

-

Filed:Mar 27, 2004

-

Appl. No.:10/810298

-

Inventors:Stephen W. Day - Dayton OH, US

G. Scott Campbell - Dayton OH, US

Danny E. Tilton - Dayton OH, US

Frederick Stoll - West Chester OH, US

Michael Sheppard - Dayton OH, US

Paul L. Galloway - Clayton OH, US -

Assignee:Webcore Technologies, Inc. - Miamisburg OH

-

International Classification:B32B 3/04

B32B 3/26 -

US Classification:428121, 4283166, 4283099, 4283179, 428 56, 428 74, 428123, 428126, 428127, 428128, 527821, 527901, 527941

-

Abstract:A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins.

-

Composite Cores And Panels

view source -

US Patent:8389104, Mar 5, 2013

-

Filed:Sep 30, 2010

-

Appl. No.:12/924612

-

Inventors:Stephen W. Day - Centerville OH, US

Michael S. Sheppard - Centerville OH, US -

Assignee:Milliken & Company - Spartanburg SC

-

International Classification:B32B 33/00

B32B 5/12 -

US Classification:428153, 416223 R, 416227 A, 416232

-

Abstract:A composite core panel has opposite side surfaces for receiving skins to form a composite sandwich panel. The core panel includes a plurality of spaced blocks of low density cellular material such as foam plastics and have opposite side surfaces forming the side surfaces of the core panel and opposite edge surfaces extending between the side surfaces. A plurality of parallel spaced elongated primary strips of structural cellular material such as balsa wood or engineered foam have a higher density and extend between the blocks, and the blocks have side surfaces adhesively attached to edge surfaces of the blocks. A plurality of parallel spaced secondary strips of structural high density cellular material such as balsa wood or engineered foam extend transversely to the primary strips and have end surfaces adhesively attached to the primary strips and side surfaces adhesively attached to the blocks.

-

Fiber Reinforced Composite Cores And Panels

view source -

US Patent:8419883, Apr 16, 2013

-

Filed:Nov 8, 2007

-

Appl. No.:11/983317

-

Inventors:Stephen W. Day - Dayton OH, US

G. Scott Campbell - Dayton OH, US

Danny E. Tilton - Dayton OH, US

Frederick Stoll - West Chester OH, US

Michael Sheppard - Dayton OH, US

Robin Banerjee - Centerville OH, US -

Assignee:Milliken & Company - Spartanburg SC

-

International Classification:B29C 65/00

B65H 81/00

B32B 5/14

B32B 7/12 -

US Classification:156264, 156169, 156172, 156191, 156195, 1563041, 1563043, 1563045, 1563046, 156428, 156430, 264145, 264148, 264151, 264241, 264257, 264258, 264259, 264263, 264265, 2642711, 264279, 2642791, 264319, 4283099, 4283166, 4283171

-

Abstract:A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips, and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins. Continuously wound strips or strip sections may be continuously fed either longitudinally or laterally into molding apparatus which may receive skin materials to form reinforced composite panels.

-

Composite Cores And Panels

view source -

US Patent:8470425, Jun 25, 2013

-

Filed:Sep 30, 2010

-

Appl. No.:12/924611

-

Inventors:Stephen W. Day - Centerville OH, US

Michael S. Sheppard - Centerville OH, US

Frederick Stoll - West Chester OH, US

Danny Tilton - Burnside KY, US -

Assignee:Milliken & Company - Spartanburg SC

-

International Classification:B29C 70/86

B32B 3/16

B31B 1/62 -

US Classification:428 53, 416223 R, 416227 A, 416232

-

Abstract:The plurality of pieces of low density cellular material, such as foam plastics, form a core panel having opposite side surfaces and with adjacent pieces having opposing edge surfaces extending between the side surfaces. Sheets of flexible material, such as veils or mats or scrim, are adhesively attached to the side surfaces, and portions of one sheet extend between the opposing adjacent edge surfaces for limiting flexing of the panel. The pieces may be tapered, and portions of the one sheet may project between the edge surfaces either partially or fully to form double wall webs. The webs may have flanges adhesively attached to the other sheet on the opposite side. One sheet may also be stretchable in areas not adhesively attached to the pieces to provide for curving the panel from a planar position maintained by the sheet on the opposite side.

-

Composite Reinforced Cores And Panels

view source -

US Patent:20120251814, Oct 4, 2012

-

Filed:Apr 4, 2011

-

Appl. No.:13/066002

-

Inventors:Stephen W. Day - Centerville OH, US

Michael S. Sheppard - Centerville OH, US

John P. Jones - Franklin OH, US

Thomas John Ewry - Trotwood OH, US

Danny E. Tilton - Dayton OH, US

Frederick Stoll - West Chester OH, US -

International Classification:B32B 5/14

B65H 81/06

B29C 65/00 -

US Classification:4283099, 156204, 156191

-

Abstract:A composite core panel is produced by arranging a plurality of foam strips in adjacent relation and advancing the strips with one or two flexible sheets of porous reinforcement material and adhesive between platens to form a panel. The sheet on one side of the strips is folded between adjacent strips to form double wall pleats which may project either partially or fully between the strips and may have folded end portions overlying the other side of the strips. The second sheet may also form double wall pleats between the strips and be connected to the pleats in the first sheet. The core panel may be cut to form reinforced strips which are connected by adhesive in various arrangements to form other core panels. A core panel may also be formed by wrapping each foam strip longitudinally with a strip of reinforcing material and connecting the strips with adhesive.

-

Composite Cores And Panels

view source -

US Patent:20130251935, Sep 26, 2013

-

Filed:May 21, 2013

-

Appl. No.:13/898927

-

Inventors:Stephen W. Day - Centerville OH, US

Michael S. Sheppard - Centerville OH, US

Frederick Stoll - West Chester OH, US

Danny Tilton - Burnside KY, US -

International Classification:B32B 3/16

B32B 37/18

E04C 2/38 -

US Classification:428 71, 527831, 156300, 428189, 428 98, 428158

-

Abstract:The plurality of pieces of low density cellular material, such as foam plastics, form a core panel having opposite side surfaces and with adjacent pieces having opposing edge surfaces extending between the side surfaces. Sheets of flexible material, such as veils or mats or scrim, are adhesively attached to the side surfaces, and portions of one sheet extend between the opposing adjacent edge surfaces for limiting flexing of the panel. The pieces may be tapered, and portions of the one sheet may project between the edge surfaces either partially or fully to form double wall webs. The webs may have flanges adhesively attached to the other sheet on the opposite side. One sheet may also be stretchable in areas not adhesively attached to the pieces to provide for curving the panel from a planar position maintained by the sheet on the opposite side.

-

Fiber Reinforced Composite Cores And Panels

view source -

US Patent:20130273308, Oct 17, 2013

-

Filed:Mar 25, 2013

-

Appl. No.:13/849924

-

Inventors:Stephen W. Day - Dayton OH, US

G. Scott Campbell - Dayton OH, US

Danny E. Tilton - Dayton OH, US

Frederick Stoll - Spartanburg SC, US

Michael Sheppard - Centerville OH, US

Robin Banerjee - Centerville OH, US -

International Classification:B32B 5/12

B32B 7/00 -

US Classification:428114

-

Abstract:A fiber reinforced core panel is formed from strips of plastics foam helically wound with layers of rovings to form webs which may extend in a wave pattern or may intersect transverse webs. Hollow tubes may replace foam strips. Axial rovings cooperate with overlying helically wound rovings to form a beam or a column. Wound roving patterns may vary along strips for structural efficiency. Wound strips may alternate with spaced strips, and spacers between the strips enhance web buckling strength. Continuously wound rovings between spaced strips permit folding to form panels with reinforced edges. Continuously wound strips are helically wrapped to form annular structures, and composite panels may combine both thermoset and thermoplastic resins. Continuously wound strips or strip sections may be continuously fed either longitudinally or laterally into molding apparatus which may receive skin materials to form reinforced composite panels.

Isbn (Books And Publications)

Democratic Consolidation, the International Dimension: Hungary, Poland, and Spain

view sourceAuthor

Stephen Day

ISBN #

3789068438

Name / Title

Company / Classification

Phones & Addresses

Director

Smith Brothers Retail, Inc

Chairman

Dover Saddlery Retail, Inc

Retailer of Equestrian Equipment

Retailer of Equestrian Equipment

DAKOTA STREET CENTER, INC

Dayton, OH

ZMD ENTERPRISE LLC

CRINKITS LLC

2DAYS, INC

President

SMITH BROTHERS, INC

508 Carroll St, Fort Worth, TX 76107

PO Box 1100, Littleton, MA 01460

PO Box 1100, Littleton, MA 01460

PANEL TECHNOLOGY, INC

Dayton, OH

Wikipedia References

Stephen Day (British Politician)

License Records

Stephen C Day

License #:

RS100830A - Expired

Category:

Real Estate Commission

Type:

Real Estate Salesperson-Standard

Resumes

Assistant To Tom Fontana At Levinson/Fontana Company

view sourcePosition:

Assistant to Tom Fontana at Levinson/Fontana Company

Location:

United States

Industry:

Motion Pictures and Film

Work:

Levinson/Fontana Company - New York City since Jan 2013

Assistant to Tom Fontana

NBC - Greater New York City Area Oct 2011 - Dec 2012

SMASH - Post Production Assistant

The Upright Citizens Brigade Theatre - Greater New York City Area Oct 2011 - May 2012

Writer's Assistant & Production Coordinator for Hot Dang!

Godlove Casting - New York City, NY Apr 2011 - Sep 2011

Casting Assistant

Celebrity Ping Pong Sep 2010 - Jun 2011

Staff Photographer & Editorial Assistant

Assistant to Tom Fontana

NBC - Greater New York City Area Oct 2011 - Dec 2012

SMASH - Post Production Assistant

The Upright Citizens Brigade Theatre - Greater New York City Area Oct 2011 - May 2012

Writer's Assistant & Production Coordinator for Hot Dang!

Godlove Casting - New York City, NY Apr 2011 - Sep 2011

Casting Assistant

Celebrity Ping Pong Sep 2010 - Jun 2011

Staff Photographer & Editorial Assistant

Education:

University of Michigan 2005 - 2009

B.A., Russian Literature & Language, English Literature & Language College for Creative Studies 2004 - 2005

University of Detroit Jesuit High School 2001 - 2005

B.A., Russian Literature & Language, English Literature & Language College for Creative Studies 2004 - 2005

University of Detroit Jesuit High School 2001 - 2005

Skills:

Final Cut Pro

Adobe Creative Suite

Russian

Film

Video Production

Video Editing

Film Production

Final Draft

Editing

Television

Avid

Photography

Producing

FileMaker

Avid Media Composer

After Effects

Creative Writing

Video

Photoshop

Social Media

Adobe Creative Suite

Russian

Film

Video Production

Video Editing

Film Production

Final Draft

Editing

Television

Avid

Photography

Producing

FileMaker

Avid Media Composer

After Effects

Creative Writing

Video

Photoshop

Social Media

Languages:

English

Russian

Russian

Sales Manager

view sourceIndustry:

Transportation/Trucking/Railroad

Work:

Southwest Truck Brokers

Sales Manager

Sales Manager

Stephen Day

view source

Stephen Day

view source

Stephen L Day

view source

Small Business Owner

view sourceWork:

Small Business Owner

Stephen Day

view source

Stephen Day

view sourceLocation:

United States

Medicine Doctors

Stephen M. Day

view sourceSpecialties:

Cardiovascular Disease

Work:

Cardiovascular GroupVirginia Heart

4660 Kenmore Ave STE 1200, Alexandria, VA 22304

7037518111 (phone), 7037511105 (fax)

4660 Kenmore Ave STE 1200, Alexandria, VA 22304

7037518111 (phone), 7037511105 (fax)

Education:

Medical School

Medical College of Wisconsin School of Medicine

Graduated: 1993

Medical College of Wisconsin School of Medicine

Graduated: 1993

Procedures:

Angioplasty

Cardiac Stress Test

Cardioversion

Pacemaker and Defibrillator Procedures

Cardiac Catheterization

Continuous EKG

Echocardiogram

Electrocardiogram (EKG or ECG)

Cardiac Stress Test

Cardioversion

Pacemaker and Defibrillator Procedures

Cardiac Catheterization

Continuous EKG

Echocardiogram

Electrocardiogram (EKG or ECG)

Conditions:

Acute Myocardial Infarction (AMI)

Atrial Fibrillation and Atrial Flutter

Cardiac Arrhythmia

Cardiomyopathy

Endocarditis

Atrial Fibrillation and Atrial Flutter

Cardiac Arrhythmia

Cardiomyopathy

Endocarditis

Languages:

Chinese

English

Spanish

English

Spanish

Description:

Dr. Day graduated from the Medical College of Wisconsin School of Medicine in 1993. He works in Alexandria, VA and specializes in Cardiovascular Disease. Dr. Day is affiliated with Inova Alexandria Hospital, Inova Fairfax Medical Campus and Virginia Hospital Center.

Stephen D. Day

view sourceSpecialties:

Family Medicine

Work:

Dekalb Medical Primary Care Group LLCStonecrest Primary Care

8225 Mall Pkwy STE 100, Lithonia, GA 30038

7709812100 (phone), 7708088445 (fax)

8225 Mall Pkwy STE 100, Lithonia, GA 30038

7709812100 (phone), 7708088445 (fax)

Education:

Medical School

University of Pittsburgh School of Medicine

Graduated: 1988

University of Pittsburgh School of Medicine

Graduated: 1988

Procedures:

Arthrocentesis

Destruction of Benign/Premalignant Skin Lesions

Electrocardiogram (EKG or ECG)

Hearing Evaluation

Skin Tags Removal

Vaccine Administration

Destruction of Benign/Premalignant Skin Lesions

Electrocardiogram (EKG or ECG)

Hearing Evaluation

Skin Tags Removal

Vaccine Administration

Conditions:

Abnormal Vaginal Bleeding

Acne

Acute Bronchitis

Acute Conjunctivitis

Acute Pharyngitis

Acne

Acute Bronchitis

Acute Conjunctivitis

Acute Pharyngitis

Languages:

English

Spanish

Spanish

Description:

Dr. Day graduated from the University of Pittsburgh School of Medicine in 1988. He works in Lithonia, GA and specializes in Family Medicine. Dr. Day is affiliated with Dekalb Medical Center At Hillandale.

Stephen V. Day

view sourceSpecialties:

Podiatric Medicine

Work:

Stephen V Day DPM

1610 James Bowie Dr STE A102, Baytown, TX 77520

2814271802 (phone), 2814273664 (fax)

1610 James Bowie Dr STE A102, Baytown, TX 77520

2814271802 (phone), 2814273664 (fax)

Procedures:

Arthrocentesis

Hallux Valgus Repair

Hallux Valgus Repair

Conditions:

Hallux Valgus

Plantar Fascitis

Tinea Pedis

Plantar Fascitis

Tinea Pedis

Languages:

English

Spanish

Spanish

Description:

Dr. Day works in Baytown, TX and specializes in Podiatric Medicine. Dr. Day is affiliated with Houston Methodist San Jacinto Hospital.

Myspace

Stephen Day

view sourceGoogleplus

Stephen Day

Work:

Quad Services - Bid/Tender Manager and Estimator (2012)

RU Stranded Pty Ltd - Director - Strategy (2011-2011)

CPM Asia Pacific - Intel Knowledge Specialist (2005-2009)

Smartek Solutions - Project Director (2001-2004)

RU Stranded Pty Ltd - Director - Strategy (2011-2011)

CPM Asia Pacific - Intel Knowledge Specialist (2005-2009)

Smartek Solutions - Project Director (2001-2004)

Education:

University of Newcastle, Australia - Arts/Law

About:

Opinionated Politico and Technophile

Bragging Rights:

Married to the most beautiful person on the planet!

Stephen Day

Work:

Serta

Education:

Cornell College

Stephen Day

Education:

Wayland Baptist University, McCurdy High School

Stephen Day

Work:

GE Healthcare - IT Consultant (2010)

Stephen Day

Work:

Keller Williams Realty - Realtor

Stephen Day

Work:

Plebnet - Administrator

Stephen Day

Stephen Day

Plaxo

Stephen Day

view source

Stephen Day

view sourceIT Director at Western Healthcare Alliance

stephen day

view sourceCox Communications

Stephen Day

view sourceSingapore

Flickr

Stephen John Day

view source

Daryl Stephen Day

view source

Stephen Rollin Day

view source

Stephen M Day

view source

Stephen Day Culver Jr.

view source

Stephen C Day

view source

Stephen F. Day

view source

Robert Stephen Day

view sourceClassmates

Stephen Day

view sourceSchools:

Univesity of Michigan Ann Arbor MI 1966-1970

Community:

Gerald Kagan, Michael Dautermann, Fern Migdal

Stephen Day

view sourceSchools:

Marion Academy Marion AL 1964-1965

Community:

Linda Kelsey, Amos Jackson, Kenneth Mahan

Stephen Day

view sourceSchools:

Akeley Elementary School Lock Haven PA 1971-1975, Flemington Elementary School Lock Haven PA 1976-1976

Community:

Scott Hartmann

Stephen Day

view sourceSchools:

Holy Spirit School Indianapolis IN 1966-1970, Brookview Elementary School Indianapolis IN 1970-1971, Lakeside Elementary School Indianapolis IN 1971-1972, Woodview Junior High School Indianapolis IN 1972-1974, Latin High School Indianapolis IN 1974-1978

Community:

Joe Miller, Bob Goins, Tony Malcak, Thomas Wagner

Stephen Day

view sourceSchools:

Palm Harbor Middle School Palm Harbor FL 1984-1986, East Lake High School Tarpon Springs FL 1987-1990

Community:

Leslie Edwards, Freedom Irvin, Gary Gonzalez

Stephen Day

view sourceSchools:

Central Catholic High School Denver CO 1974-1978

Community:

Carl Glick, Dave Hastings, Barbara Espinoza, Julie Glotzbach, Renee Cabral

Youtube

Get Report for Stephen M Day from Tipp City, OH, age ~86