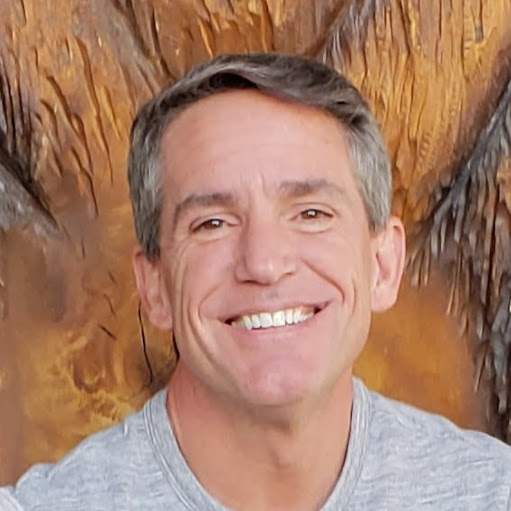

Thomas Charles Magee

age ~63

from San Jose, CA

- Also known as:

-

- Thomas C Magee

- Tom Magee

- Tom C Mcgee

- Phone and address:

-

1970 Coastland Ave, San Jose, CA 95125

4088396018

Thomas Magee Phones & Addresses

- 1970 Coastland Ave, San Jose, CA 95125 • 4088396018

- Campbell, CA

- 1970 Coastland Ave, San Jose, CA 95125

Work

-

Position:Administration/Managerial

Education

-

School / High School:Syracuse University College of Law

Ranks

-

Licence:New York - Currently registered

-

Date:1981

Emails

Lawyers & Attorneys

Thomas J. Magee - Lawyer

view sourceOffice:

HeplerBroom LLC

Phone:

3144804212 (Phone)

Specialties:

Products Liability

Insurance Coverages

Automobile

Professional Malpractice

Insurance Coverages

Automobile

Professional Malpractice

ISLN:

905253549

Admitted:

1985, Missouri

1986, Illinois

1985, U.S. District Court, Eastern District of Missouri

1987, U.S. Court of Appeals, Eighth Circuit

1989, U.S. Supreme Court

1990, U.S. District Court, Southern District of Illinois

1991, U.S. District Court, Western District of Missouri

2003, U.S. Court of Appeals, Seventh Circuit

1986, Illinois

1985, U.S. District Court, Eastern District of Missouri

1987, U.S. Court of Appeals, Eighth Circuit

1989, U.S. Supreme Court

1990, U.S. District Court, Southern District of Illinois

1991, U.S. District Court, Western District of Missouri

2003, U.S. Court of Appeals, Seventh Circuit

University:

Marquette University, Milwaukee, WI, B.S., 1982

Law School:

St. Louis University School of Law, J.D., cum laude, 1985

Links:

Site

Biography:

Recognized by: Super Lawyers <br /><br />Practice Description: <br /><br />Mr. Magee focuses his practice on trials involving complex litigation matters, including: <br /><br />· Products liabili...

Thomas H. Magee - Lawyer

view sourceLicenses:

New York - Currently registered 1981

Education:

Syracuse University College of Law

Thomas Magee - Lawyer

view sourceOffice:

Thomas M. Magee

Specialties:

Criminal Law

Family Law

Civil Litigation

Family Law

Civil Litigation

ISLN:

909724045

Admitted:

1994

University:

Texas Tech University, B.A., 1981

Law School:

University of South Dakota, J.D., 1994

Resumes

Business Analyst, Software Consultant, Project Manager

view sourceWork:

Init

Business Analyst, Software Consultant, Project Manager

Business Analyst, Software Consultant, Project Manager

Thomas Magee

view source

Thomas Magee

view source

Thomas Magee

view source

Thomas Magee

view source

Thomas Magee

view sourceWork:

Dr Thomas J Magee M.d

Executive

Dr Thomas J Magee M.d

Technician at Earthlink

Executive

Dr Thomas J Magee M.d

Technician at Earthlink

Thomas Magee

view source

Director, Global It Operations At Triquint Semiconductor

view sourcePosition:

Director, Global IT Operations at TriQuint Semiconductor

Location:

Tualatin, Oregon

Industry:

Semiconductors

Work:

TriQuint Semiconductor - Hillsboro, Oregon since Sep 2009

Director, Global IT Operations

Mentor Graphics Corporation Jul 2004 - Sep 2009

Enterprise Client Environments Manager

Mentor Graphics Oct 1998 - Jul 2004

Communication Services Manager

Director, Global IT Operations

Mentor Graphics Corporation Jul 2004 - Sep 2009

Enterprise Client Environments Manager

Mentor Graphics Oct 1998 - Jul 2004

Communication Services Manager

Education:

Azusa Pacific University 1989 - 1992

MA, Human Resource Leadership George Fox University 1981 - 1985

BA, Buseinss/Economics

MA, Human Resource Leadership George Fox University 1981 - 1985

BA, Buseinss/Economics

Skills:

Team Building

IT Operations

Public Speaking

Contract Negotiation

Improvisation

Open Source

Project Management

Program Management

IT Service Management

Troubleshooting

Team Leadership

Cross-functional Team Leadership

ITIL

IT Operations

Public Speaking

Contract Negotiation

Improvisation

Open Source

Project Management

Program Management

IT Service Management

Troubleshooting

Team Leadership

Cross-functional Team Leadership

ITIL

Us Patents

-

Memory System Using Ion Implanted Photodichroic Materials

view source -

US Patent:39720322, Jul 27, 1976

-

Filed:Sep 9, 1974

-

Appl. No.:5/504058

-

Inventors:Thomas J. Magee - Belmont CA

Matt Lehmann - Menlo Park CA -

Assignee:Stanford Research Institute - Menlo Park CA

-

International Classification:G11C 1142

G11C 1304 -

US Classification:340173CC

-

Abstract:There is provided a method and means for establishing storage sites in photodichroic materials using ion implantation.

-

Method Of Controlled Surface Texturization Of Crystalline Semiconductor Material

view source -

US Patent:41475640, Apr 3, 1979

-

Filed:Nov 18, 1977

-

Appl. No.:5/852786

-

Inventors:Thomas J. Magee - Belmont CA

Richard R. Pettijohn - Portola Valley CA

Shelley A. Stewart - Santa Clara CA

Malcolm Thackray - Stanford CA -

Assignee:SRI International - Menlo Park CA

-

International Classification:H01L 21306

-

US Classification:148 15

-

Abstract:A method of forming a microscopically texturized surface on a crystalline semiconductor material is disclosed which method includes the use of a radioactive source for uniformly irradiating the surface. The radioactive source includes a plane surface having a uniform distribution of radioactive material thereon In one arrangement the radioactive source surface area is at least the size of the polished crystalline semiconductor surface to be texturized, and the radioactive source is positioned closely adjacent the polished surface for a predetermined time period for uniform irradiation of the same. If desired, the radioactive source and crystalline surface may be relatively movable during irradiation of the surface, in which case the source may be in the form of an elongated strip of sufficient length to extend beyond opposite edges of the polished surface area to be texturized. In any case, the large-surface area radioactive source produces substantially uniform distribution of damage tracks in the crystalline surface, which surface then is anisotropically etched by use of a suitable etching solution. The damage tracks provide etching sites along which etching proceeds at a greater rate than in the undamaged area.

-

Laser Planarization Of Nonrefractory Metal During Integrated Circuit Fabrication

view source -

US Patent:47585331, Jul 19, 1988

-

Filed:Sep 22, 1987

-

Appl. No.:7/099792

-

Inventors:Thomas J. Magee - Belmont CA

John F. Osborne - Sunnyvale CA

Peter Gildea - Sunnyvale CA

Charles H. Leung - San Jose CA -

Assignee:XMR Inc. - Santa Clara CA

-

International Classification:H01L 21268

-

US Classification:437173

-

Abstract:Nonrefractory micrometer-thick deposited metal or metallization, for example, aluminum and aluminum alloy films, on integrated circuits are planarized by momentarily melting them with optical pulses from a laser, such as a xenon chloride excimer laser. The substrate, as well as any intervening dielectric and conducive layers, are preheated to preferably one-half the melting temperature of the metal to be planarized, thereby enhancing reflow of the metal upon melting. This improves planarization and reduces stress in the resolidified metal. Laser planarization offers an attractive technique for fabricating multilayer interconnect structures, particularly where a number of ground or power planes are included. Excellent step coverage and via filling is achieved without damaging lower layers of interconnect.

-

Method For Cleaning Surfaces Using Uv Lasers

view source -

US Patent:51511355, Sep 29, 1992

-

Filed:Sep 15, 1989

-

Appl. No.:7/407817

-

Inventors:Thomas J. Magee - Belmont CA

Charles S. Leung - San Jose CA

Richard L. Press - San Jose CA -

Assignee:Amoco Corporation - Chicago IL

-

International Classification:H01L 21268

B08B 700 -

US Classification:134 1

-

Abstract:The invention relates to a new method for cleaning chemical, metallic and particulate contaminants from solid surfaces. The new method comprises irradiating the surface with essentially ultraviolet laser radiation whose parameters are selected to avoid causing substantial chemical or physical change at the surface.

Medicine Doctors

Thomas H. Magee

view sourceSpecialties:

Radiology

Work:

Neuroskeletal Imaging Institute

2222 S Hbr City Blvd STE 520, Melbourne, FL 32901

3214099990 (phone), 3214099989 (fax)

Neuroskeletal Imaging

1315 S Orange Ave STE 1B, Orlando, FL 32806

4079999977 (phone), 4079999988 (fax)

2222 S Hbr City Blvd STE 520, Melbourne, FL 32901

3214099990 (phone), 3214099989 (fax)

Neuroskeletal Imaging

1315 S Orange Ave STE 1B, Orlando, FL 32806

4079999977 (phone), 4079999988 (fax)

Education:

Medical School

New York Medical College

Graduated: 1986

New York Medical College

Graduated: 1986

Languages:

English

Spanish

Spanish

Description:

Dr. Magee graduated from the New York Medical College in 1986. He works in Melbourne, FL and 1 other location and specializes in Radiology.

Classmates

Thomas Magee

view sourceSchools:

McAdory High School Mccalla AL 2002-2006

Community:

Linda Franklin, Barbara Norris

Thomas Magee

view sourceSchools:

Central High School Chestertown NY 1961-1965

Community:

Barbara Barrett, Ray Strickland, Mindie Seiferth, David Bedell

Thomas Magee

view sourceSchools:

Valley Center High School Valley Center CA 2000-2004

Thomas Magee, Pine Tree H...

view source

Thomas Magee | Tarpon Spr...

view source

Thomas Magee | Franklinto...

view source

thomas darcy magee, Montr...

view source

Central High School, Ches...

view sourceGraduates:

Lucretia Ellsworth (1941-1945),

Lucy Baker (1978-1979),

Patricia Woods (1967-1971),

Thomas Magee (1961-1965)

Lucy Baker (1978-1979),

Patricia Woods (1967-1971),

Thomas Magee (1961-1965)

Flickr

Myspace

Googleplus

Thomas Magee

Work:

TriQuint Semiconductor - IT Operations Manager (2009)

Mentor Graphics - Network and Desktop Manager (1993-2009)

Mentor Graphics - Network and Desktop Manager (1993-2009)

Thomas Magee

Work:

Celtic Root - Landscaper/Carpenter

Education:

Downingtown West High School

Thomas Magee

Work:

KopyKatDR - Owner (1)

Thomas Magee

Thomas Magee

Thomas Magee

Thomas Magee

Thomas Magee

Thomas C. Magee

view source

Thomas Magee

view source

Thomas Magee

view source

Thomas Magee

view source

Thomas Magee

view source

Thomas Magee

view source

Thomas Magee

view source

Thomas Magee

view sourcePlaxo

Gloria Thomas MaGee

view sourceNew Orleans, LAAssistant Professor at Xavier University of Louisi... Past: Assistant Professor at Mississippi State University, Postdoctoral Fellow at National...

Youtube

Get Report for Thomas Charles Magee from San Jose, CA, age ~63