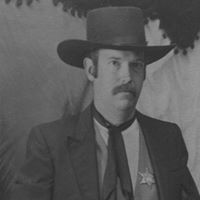

Lloyd K Duncan

Deceased

from Pacific, MO

- Also known as:

-

- Lloyd Kenton Duncan

- Lloyd J Duncan

- Lloyd Duncaninc

- Phone and address:

-

545 Osage St, Pacific, MO 63069

6362573088

Lloyd Duncan Phones & Addresses

- 545 Osage St, Pacific, MO 63069 • 6362573088 • 6362578348 • 6362713478

Resumes

Lloyd Duncan

view source

Lloyd Duncan

view source

Lloyd Duncan

view source

Lloyd Duncan

view sourceUs Patents

-

Milking Device

view source -

US Patent:42878535, Sep 8, 1981

-

Filed:Mar 24, 1980

-

Appl. No.:6/133313

-

Inventors:Lloyd P. Duncan - Washington MO

-

International Classification:A01J 504

-

US Classification:119 1455

-

Abstract:A milker has a lower base with a concave bottom and a lower exit under vacuum that can be closed by a float with valve until the milk level pivots and/or raises the float to open the exit. An enclosure body is fitted on the base and includes a main vacuum inlet and a milk inlet nipple positioned and angled to direct milk inflow at the side and/or below the float. An enclosure cap is releasably fitted on the top of the enclosure body and mounts an air valve, pulsation nipples and a further vacuum inlet. A central stem from the bottom extends up through a central passageway in the float and also through the cap to afford a fulcrum or support for an arm that pivots or slides to close the main vacuum inlet when the air valve is opened. The float can pivot and rise to a limited extent when milking or when the milker is inverted for washing. The assembled cap, enclosure body and base are interfitted and sealed when the inlets and milk outlet are in alignment.

-

Stretched Teat Cup

view source -

US Patent:39735214, Aug 10, 1976

-

Filed:May 12, 1975

-

Appl. No.:5/576248

-

Inventors:Lloyd P. Duncan - Washington MO

-

International Classification:A01J 504

-

US Classification:119 1447

-

Abstract:A teat cup has an outer rigid shell and an inner flexible inflation to receive an animal's teat in a pulsating elastic bore which is stretched by a spring or retaining member positioned between the shell and inflation. The stretched upper portion of the inflation becomes more responsive to the pulsations during milking. The spring member is fitted to the inflation near the upper mouth of the bore so that the member's lower portion bears on the inner surfaces of the shell or the spring member's shape inherently stretches the upper inflation area. Notches or openings and/or apertures are provided in the spring member to allow movement of the member as well as drainage of the teat cup when same is washed and inverted to dry.

-

Pulsating Teat Cups

view source -

US Patent:39317951, Jan 13, 1976

-

Filed:Jul 11, 1974

-

Appl. No.:5/487781

-

Inventors:Lloyd P. Duncan - Washington MO

-

International Classification:A01J 516

-

US Classification:119 1438

-

Abstract:A teat cup has a shell and an inner flexible inflation that hermetically seals each end of the shell, preferably leaving an elliptical space between the outer surface of the inflation and the inner surface of the shell. An aperture or opening in the shell communicates air to relieve the vacuum in the space when a valve in the aperture is moved by the collapsing and flattened inflation. The valve can be moved by the inflation located in the space or the valve can be pivoted by the flattened inflation to expose or register with a vacuum source or ambient atmosphere. The inflation is pulsed by a constant source of vacuum connected to an entrance that also leads to the space. The entrance can be valved shut by the inflation and a projection on same that is closely adjacent to the entrance. Also, a pair of inflations have their valved apertures interconnected to one another by a first conduit and a source of constant vacuum in communication with the entrances of the shells connected to one another by a second conduit so that the tandem pulsation of the inflations moves air back and forth through the first conduit.

-

Pulsation System

view source -

US Patent:40347125, Jul 12, 1977

-

Filed:Nov 24, 1975

-

Appl. No.:5/634331

-

Inventors:Lloyd P. Duncan - Washington MO

-

International Classification:A01J 504

-

US Classification:119 1436

-

Abstract:Teat cups are pulsed by a valve in a duct leading from the shell into the pulsation space between a resilient inflation and the shell. The valve alternately opens the pulsation space to ambient pressure and to a source of vacuum. The source of vacuum in the receiver or milk lines is in communication with the pulsation space through a tube or passage that is controlled by the valve. A timer connected to a solenoid actuator for the valve unseats the valve to allow air to enter the pulsation space, whereupon the inflation assumes a normal configuration. Upon seating to close ambient air entry while establishing vacuum to the space, the vacuum flattens the inflation. The timer sequences the air movement to ensure that milk flowing to the receiver clears the milk from the inflation and prevents back flow to the animal's teats.

Lloyd Duncan

view source

Lloyd Duncan

view source

Lloyd Duncan

view source

Lloyd Duncan

view source

Lloyd Duncan

view source

Lloyd Duncan

view source

Lloyd Duncan

view source

Lloyd Ray Duncan

view sourceYoutube

Myspace

Classmates

Lloyd Duncan

view sourceSchools:

Whiteland Elementary School Whiteland IN 1948-1958

Community:

Stephanie Anderson, John Lewis, Sherry Devine, Kathy Janeway, Connie Pendleton

Lloyd Duncan

view sourceSchools:

Roachdale High School Roachdale IN 1945-1949

Community:

Susan Gilstrap, Mike Beck, Steve Parker, Michelle Donovan, Taylor Graham

Lloyd Duncan

view sourceSchools:

Newton-Conover High School Newton NC 1981-1985

Community:

Jonathan Birchfield, Paula Yount, Jackie Hartsoe, Tony Haney, Alison Madden, Diane Suddreth

Lloyd Duncan, Colfax High...

view source

Akiva School, Nashville, ...

view sourceGraduates:

Lloyd Duncan (1968-1972),

Yonatan Limor (1988-1994),

Sean Preston (1983-1990),

Esther King (1974-1978)

Yonatan Limor (1988-1994),

Sean Preston (1983-1990),

Esther King (1974-1978)

Roachdale High School, Ro...

view sourceGraduates:

Lori Hoyle (1977-1981),

Lloyd Duncan (1945-1949),

Crystal Gatlin (1986-1990),

Patricia Osborne (1955-1959)

Lloyd Duncan (1945-1949),

Crystal Gatlin (1986-1990),

Patricia Osborne (1955-1959)

Duncan Lloyd | Richmond C...

view source

Northern State University...

view sourceGraduates:

Lloyd Duncan (1962-1966),

Bill Benedict (1977-1981),

Denita Hove (1990-1996),

Sarah Rausch (1993-1999),

Vicki Matta (2003-2003),

Tom Schmitt (1953-1957)

Bill Benedict (1977-1981),

Denita Hove (1990-1996),

Sarah Rausch (1993-1999),

Vicki Matta (2003-2003),

Tom Schmitt (1953-1957)

Googleplus

Lloyd Duncan

Lloyd Duncan

Lloyd Duncan

Lloyd Duncan

Lloyd Duncan

Get Report for Lloyd K Duncan from Pacific, MODeceased

![Duncan Lloyd - Red Moon [Official Video] Duncan Lloyd - Red Moon [Official Video]](https://i.ytimg.com/vi/PVNEZmaZZZ4/hqdefault.jpg?sqp=-oaymwEcCOADEI4CSFXyq4qpAw4IARUAAIhCGAFwAcABBg==&rs=AOn4CLBg5JLELhw9VHaOSA7FSS03m10mjw)

![Duncan Lloyd - Young Dreams [Official Video] Duncan Lloyd - Young Dreams [Official Video]](https://i.ytimg.com/vi/zAnYIGUM6vg/hqdefault.jpg?sqp=-oaymwEcCOADEI4CSFXyq4qpAw4IARUAAIhCGAFwAcABBg==&rs=AOn4CLBlmGQOS42JQjy02JfeTrCLitQXwQ)

![Duncan Lloyd - Really [Official Video] Duncan Lloyd - Really [Official Video]](https://i.ytimg.com/vi/ox_oyZmVpzY/hq720.jpg?sqp=-oaymwEcCNAFEJQDSFXyq4qpAw4IARUAAIhCGAFwAcABBg==&rs=AOn4CLDsncF3KfPWhoPyFJ0ic_po-l4FfA)

![Duncan Lloyd - A Chime [Official Video] Duncan Lloyd - A Chime [Official Video]](https://i.ytimg.com/vi/Wl0AXEcJfiY/hqdefault.jpg?sqp=-oaymwE2COADEI4CSFXyq4qpAygIARUAAIhCGAFwAcABBvABAfgB_gSAAuADigIMCAAQARhlIGUoZTAP&rs=AOn4CLCXPEOWSmAmAixuir9sOfxBjZ3yzw)

![Duncan Lloyd - Heart In Delay [Official Video] Duncan Lloyd - Heart In Delay [Official Video]](https://i.ytimg.com/vi/yPmgOLX2qsU/hq720.jpg?sqp=-oaymwEcCNAFEJQDSFXyq4qpAw4IARUAAIhCGAFwAcABBg==&rs=AOn4CLDgtFsz81dk8ZR0UCBkXTe0kcoCGA)