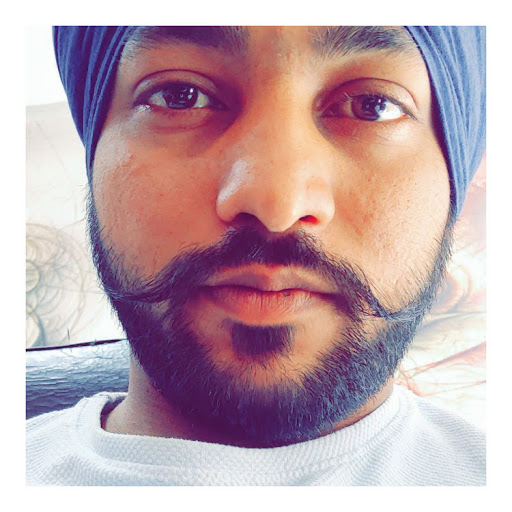

Jugraj S Singh

age ~61

from Lake Orion, MI

- Also known as:

-

- Jugra J Singh

- Sandeep Singh

- Jagraj Singh

- Ugra Singh

- Singh Jugraj

- J Singh

- Phone and address:

-

3337 Glacier Dr, Lake Orion, MI 48360

2483933363

Jugraj Singh Phones & Addresses

- 3337 Glacier Dr, Lake Orion, MI 48360 • 2483933363

- Oakland, MI

- Detroit, MI

- Everett, WA

- 3337 Glacier Dr, Lake Orion, MI 48360 • 2488637094

Work

-

Company:7-elevenOct 2014

-

Position:Cashier

Education

-

School / High School:Punjabi University- Patiala, Punjab1985

-

Specialities:Economics

Emails

Us Patents

-

Elevated Temperature Forming Method And Preheater Apparatus

view source -

US Patent:20100192659, Aug 5, 2010

-

Filed:Feb 5, 2009

-

Appl. No.:12/366310

-

Inventors:Paul Edward Krajewski - Troy MI, US

Richard Harry Hammar - Shelby Township MI, US

Jugraj Singh - Lake Orion MI, US

Dennis Cedar - Rochester MI, US

Peter A. Friedman - Ann Arbor MI, US

Yingbing Luo - Ann Arbor MI, US -

International Classification:B21D 22/00

F27B 9/00 -

US Classification:72349, 432121

-

Abstract:An elevated temperature forming system in which a sheet metal workpiece is provided in a first stage position of a multi-stage pre-heater, is heated to a first stage temperature lower than a desired pre-heat temperature, is moved to a final stage position where it is heated to a desired final stage temperature, is transferred to a forming press, and is formed by the forming press. The preheater includes upper and lower platens that transfer heat into workpieces disposed between the platens. A shim spaces the upper platen from the lower platen by a distance greater than a thickness of the workpieces to be heated by the platens and less than a distance at which the upper platen would require an undesirably high input of energy to effectively heat the workpiece without being pressed into contact with the workpiece.

-

Elevated Temperature Forming Method And Preheater Apparatus

view source -

US Patent:20130205854, Aug 15, 2013

-

Filed:Mar 7, 2013

-

Appl. No.:13/788918

-

Inventors:Richard Harry Hammar - Shelby Township MI, US

Jugraj Singh - Lake Orion MI, US

Dennis Cedar - Rochester MI, US

Peter A. Friedman - Ann Arbor MI, US

Yingbing Luo - Ann Arbor MI, US -

Assignee:USAMP - Southfield MI

-

International Classification:B21D 22/20

B21D 24/16 -

US Classification:72 38, 72347, 723427, 72338, 72325, 72348

-

Abstract:An elevated temperature forming system in which a sheet metal workpiece is provided in a first stage position of a multi-stage pre-heater, is heated to a first stage temperature lower than a desired pre-heat temperature, is moved to a final stage position where it is heated to a desired final stage temperature, is transferred to a forming press, and is formed by the forming press. The preheater includes upper and lower platens that transfer heat into workpieces disposed between the platens. A shim spaces the upper platen from the lower platen by a distance greater than a thickness of the workpieces to be heated by the platens and less than a distance at which the upper platen would require an undesirably high input of energy to effectively heat the workpiece without being pressed into contact with the workpiece.

-

Method Of Incremental Cold Forming An Angled Corner In A Continuous Sheet Of Advanced High Strength Metal

view source -

US Patent:20180021832, Jan 25, 2018

-

Filed:Jul 20, 2016

-

Appl. No.:15/214510

-

Inventors:Dajun Zhou - Troy MI, US

Changqing Du - Troy MI, US

Robert D Miller - Lake Orion MI, US

Jugraj Singh - Lake Orion MI, US -

International Classification:B21D 22/02

-

Abstract:An outer bend radius is cold formed in an outer position within a final arc of the angled corner with an outer bend radius male die member. A central bend radius is cold formed in a central position spaced from the outer position and within the final arc of the angled corner with a central bend radius male die member. An inner bend radius is cold formed in an inner position that is spaced from the outer and central positions and the inner position is within a final arc of the angled corner with an inner bend radius male die member. The angled corner is transferred between each of the bend radii male die members using a continuous advanced high strength metal sheet in which the angled corner is formed.

Wikipedia

Jugraj Singh

view sourceJugraj Singh, born in 1983 to a sikh family in Punjab. A self coached drag- flicker who became a youth icon for anybody who ever followed Indian Hockey or ...

Resumes

Senior Technical Specialist

view sourceLocation:

3337 Glacier Dr, Lake Orion, MI 48360

Industry:

Automotive

Work:

Fca Fiat Chrysler Automobiles

Senior Technical Specialist

Fca Fiat Chrysler Automobiles Nov 2003 - Nov 2016

Materials Specialist at Chrysler

General Motors Jul 1997 - Oct 1999

Product Design

Boeing Sep 1995 - Jul 1997

Product Design

Barc Sep 1987 - Sep 1992

Research Scientist

Senior Technical Specialist

Fca Fiat Chrysler Automobiles Nov 2003 - Nov 2016

Materials Specialist at Chrysler

General Motors Jul 1997 - Oct 1999

Product Design

Boeing Sep 1995 - Jul 1997

Product Design

Barc Sep 1987 - Sep 1992

Research Scientist

Education:

University of Windsor 1992 - 1994

Masters, Engineering Indian Institute of Technology (Banaras Hindu University), Varanasi 1983 - 1987

Masters, Engineering Indian Institute of Technology (Banaras Hindu University), Varanasi 1983 - 1987

Skills:

Automotive

Product Design

Root Cause Analysis

Ppap

Fmea

Cae

Product Design

Root Cause Analysis

Ppap

Fmea

Cae

Interests:

Kids

Electronics

Outdoors

Sweepstakes

Reading

Automobiles

Travel

Electronics

Outdoors

Sweepstakes

Reading

Automobiles

Travel

Languages:

English

Jugraj Singh

view source

Jugraj Veer Singh

view source

Jugraj Singh

view sourceWork:

7-Eleven

Oct 2014 to 2000

Cashier US Market

Dec 2013 to Oct 2014

Cashier (Customer care, store supervisor)

Oct 2014 to 2000

Cashier US Market

Dec 2013 to Oct 2014

Cashier (Customer care, store supervisor)

Education:

Punjabi University

Patiala, Punjab

1985

Economics Punjabi University

Patiala, Punjab

1983

Economics and Political Science

Patiala, Punjab

1985

Economics Punjabi University

Patiala, Punjab

1983

Economics and Political Science

Youtube

Googleplus

Jugraj Singh

Work:

SSJCO - ARTICLE

Education:

Mumbai University Institute of Chemical Technology - COMMERCE

About:

IT ALWAYS ME & MYSELF WHICH MATTERS AT THE END.

Jugraj Singh

Education:

St.joseph

Jugraj Singh

Jugraj Singh

Jugraj Singh

Jugraj Singh

Jugraj Singh

Jugraj Singh

Flickr

Jugraj Singh Sandhu

view source

Jugraj Singh Singh

view source

Jugraj Singh

view source

Jugraj Singh

view source

Jugraj Singh

view source

Jugraj Singh

view source

Jugraj Singh

view source

Jugraj Singh

view sourceMyspace

Classmates

Jugraj Singh

view sourceSchools:

Benjamin Banneker Middle School Burtonsville MD 2005-2009

Community:

Kim Hodge, Palmer Allen

Jugraj Singh | Royal Cent...

view source

Benjamin Banneker Middle ...

view sourceGraduates:

Jugraj Singh (2005-2009),

Pascal Yang (2000-2004),

Merrica Barr (1996-2000),

Cede Derricott (1999-2003),

tony Jones (1993-1995)

Pascal Yang (2000-2004),

Merrica Barr (1996-2000),

Cede Derricott (1999-2003),

tony Jones (1993-1995)

Get Report for Jugraj S Singh from Lake Orion, MI, age ~61