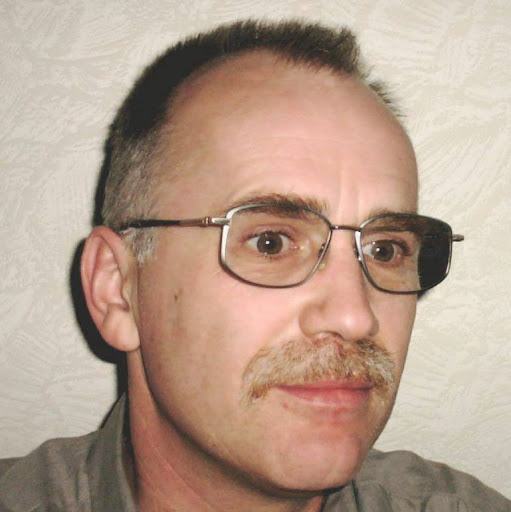

Peter A Gruber

age ~69

from Mohegan Lake, NY

Peter Gruber Phones & Addresses

- 5 Kings Ct, Mohegan Lake, NY 10547 • 9145282013

- 5 Kings Ct APT D, Mohegan Lake, NY 10547 • 9145282013

- Saint Augustine, FL

- Fishkill, NY

- Mount Kisco, NY

- Brewster, NY

- 5 Kings Ct APT D, Mohegan Lake, NY 10547

Work

-

Company:WEILER DIVISION-MONTEFIORE HOSPITAL

-

Address:1825 Eastchester Rd, Bronx, NY 10461

-

Phones:7189206626 7189042517

Education

-

School / High School:New York Medical College1988

Languages

English

Awards

Healthgrades Honor Roll

Ranks

-

Certificate:Emergency Medicine, 2004

Emails

Specialities

Emergency Medicine

Lawyers & Attorneys

Peter Gruber - Lawyer

view sourceOffice:

Slingerland & Clark, P.C.

Specialties:

Criminal Defense

Criminal Defense

Criminal Defense

ISLN:

917231757

Admitted:

1991

Law School:

Loyola University, J.D.

Us Patents

-

Method For Making Interconnect For Low Temperature Chip Attachment

view source -

US Patent:6340630, Jan 22, 2002

-

Filed:Mar 28, 2000

-

Appl. No.:09/536557

-

Inventors:Daniel George Berger - Wappingers Falls NY

Guy Paul Brouillette - Daudelin, CA

David Hirsch Danovitch - Des Aigles, CA

Peter Alfred Gruber - Mohegan Lake NY

Bruce Lee Humphrey - Jericho VT

Michael Liehr - Yorktown Heights NY

William Thomas Motsiff - Essex Junction VT

Carlos Juan Sambucetti - Croton-on-Hudson NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:A01L 2144

-

US Classification:438613, 438612, 438614, 438616

-

Abstract:A method of forming interconnects on an electronic device that can be bonded to another electronic device at a low processing temperature can be carried out by depositing a first interconnect material on the electronic device forming protrusions and then depositing a second interconnect material to at least partially cover the protrusions, wherein the second interconnect material has a lower flow temperature than the first interconnect material. The method is carried out by flowing a molten solder into a mold having microcavities to fill the cavities and then allowed to solidify. The mold is then aligned with a silicon wafer containing chips deposited with high melting temperatures solder bumps such that each microcavity of the mold is aligned with each high melting temperature solder bump on the chip. The aligned mold/wafer assembly is then passed through a reflow furnace to effect the transfer of the low melting temperature solder in the mold cavities onto the tip of the high melting temperature solder bumps on the wafer. A dual metallurgical composition bump is thereby formed by the two different solder alloys.

-

Method For Direct Chip Attach By Solder Bumps And An Underfill Layer

view source -

US Patent:6341418, Jan 29, 2002

-

Filed:Apr 29, 1999

-

Appl. No.:09/301890

-

Inventors:Guy P. Brouillette - Canton Shefford, CA

David H. Danovitch - Granby, CA

Peter A. Gruber - Mohegan Lake NY

Michael Liehr - Essex Junction VT

Carlos J. Sambucetti - Croton Hudson NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:H05K 334

-

US Classification:29840, 29832, 29833, 12818022

-

Abstract:A method for direct chip attach of a semiconductor chip to a circuit board by using solder bumps and an underfill layer is disclosed. In the method, a layer of in-situ polymeric mold material is first screen printed on the top surface of the semiconductor chip exposing a multiplicity of bond pads. The in-situ polymeric mold layer is formed with a multiplicity of apertures which are then filled with solder material in a molten solder screening process to form solder bumps. A thin flux-containing underfill material layer is then placed on top of a circuit board over a plurality of conductive pads which are arranged in a mirror image to the bond pads on the semiconductor chip. The semiconductor chip and the circuit board are then pressed together with the underfill layer inbetween and heated to a reflow temperature of higher than the melting temperature of the solder material until electrical communication is established between the bond pads and the conductive pads. In the bonded assembly, the in-situ polymeric mold layer and the underfill material layer forms a composite underfill to replace a conventional underfill material that must be injected between bonded chip and substrate by a capillary action in a time consuming process.

-

Ultrasonic Method And Actuator For Inducing Motion Of An Object

view source -

US Patent:6362557, Mar 26, 2002

-

Filed:Aug 28, 2000

-

Appl. No.:09/649486

-

Inventors:Peter A. Gruber - Mohegan Lake NY

Frederic Maurer - Valhalla NY

George F. Walker - New York NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:H01L 4108

-

US Classification:31032302, 31032316

-

Abstract:An actuator scaled to macroscopic or microscopic sizes, uses ultrasonic energy to induce motion of an object in a desired direction. The actuator includes one or more pair of piezoelectric transducers connected with a transducer tip. Supplying the piezoelectric transducers with alternating current electrical power causes the tip to vibrate at ultrasonic frequencies. Urging the vibrating tip into contact with a surface on the object at a selected angle of inclination induces the object to move in the desired direction at a rate determined by the inclination angle. Multiple actuators can be used to induce a fall range of movements of variously shaped objects. In microscopic form, the actuator can be used to create a MEMS device. The optional application of a compliant material either on the transducer tip or on the objects surface enhances the movement induced by the actuator.

-

Hybrid Molds For Molten Solder Screening Process

view source -

US Patent:6390439, May 21, 2002

-

Filed:Apr 7, 1999

-

Appl. No.:09/287370

-

Inventors:Steven A. Cordes - Cortlandt Manor NY

David Hirsch Danovitch - Quebec, CA

Peter Alfred Gruber - Mohegan Lake NY

James Louis Speidell - Poughquaq NY

Joseph Peter Zinter - Brewster NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:B29C 3300

-

US Classification:249119, 249134, 249139, 156 60, 264219, 216 79, 216 99

-

Abstract:Hybrid molds for molding a multiplicity of solder balls for use in a molten solder screening process and methods for preparing such molds are disclosed. A method for forming the multiplicity of cavities in a pyramidal shape by anisotropically etching a crystalline silicon substrate along a specific crystallographic plane is utilized to form a crystalline silicon face plate used in the present invention hybrid mold. In a preferred embodiment, a silicon face plate is bonded to a borosilicate glass backing plate by adhesive means in a method that ensures coplanarity is achieved between the top surfaces of the silicon face plate and the glass backing plate. In an alternate embodiment, an additional glass frame is used for bonding a silicon face plate to a glass backing plate, again with ensured coplanarity between the top surfaces of the silicon face plate and the glass frame. In a second alternate embodiment, a silicon face plate is encased in an extender material which may be borosilicate glass or a polymer. The encasing is performed on a leveling fixture such that the top surface of the silicon face plate and the top surface of the extender material after solidification are perfectly leveled.

-

Method And Apparatus For Forming Solder Bumps

view source -

US Patent:6394334, May 28, 2002

-

Filed:Mar 28, 2000

-

Appl. No.:09/536810

-

Inventors:Guy Paul Brouillette - Quebec, CA

Peter Alfred Gruber - Mohegan Lake NY

Frederic Maurer - Valhalla NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:B23K 100

-

US Classification:228 33, 228215

-

Abstract:The present invention discloses a method and apparatus for forming solder bumps by a molten solder screening technique in which a flexible die head constructed of a metal sheet is utilized for maintaining an intimate contact between the die head and a solder receiving mold surface, The flexible die head, when used in combination with a pressure means, is capable of conforming to any curved mold surface as long as the curvature is not more than 2. 5 m per inch of die length. The present invention further provides a method and apparatus for filling a multiplicity of cavities in a mold surface by providing a stream of molten solder and then intimately contacting the surface of the molten solder with a multiplicity of cavities such that the molten solder readily fills the cavities. The apparatus further provides means for removing excess molten solder from the surface of the mold without disturbing the molten solder already filled in the cavities. The present invention further discloses a flexible die for dispensing molten solder consisting of a die body that is constructed of a metal sheet capable of flexing of not less than 1.

-

Method And Apparatus For Applying Solder To An Element On A Substrate

view source -

US Patent:6425518, Jul 30, 2002

-

Filed:Jul 25, 2001

-

Appl. No.:09/912845

-

Inventors:Peter Alfred Gruber - Mohegan Lake NY

Chon Cheong Lei - Poughkeepsie NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:B23K 3102

-

US Classification:228256, 228223, 22818021

-

Abstract:There is provided a method for applying solder to an element on a surface of a substrate. The method comprises the steps of (a) placing a mold over the surface, where the mold includes a conduit that contains the solder, and (b) heating the solder to a molten state so that the solder flows from the conduit onto the element. The conduit enjoys two degrees of horizontal freedom with respect to the surface such that the conduit becomes substantially aligned with the element when the solder is in the molten state. There is also provided a system for applying solder to an element on a surface of a substrate.

-

Method For Forming Three-Dimensional Circuitization And Circuits Formed

view source -

US Patent:6426241, Jul 30, 2002

-

Filed:Nov 12, 1999

-

Appl. No.:09/439112

-

Inventors:Steven A. Cordes - Cortlandt Manor NY

Peter A. Gruber - Mohegan Lake NY

James L. Speidell - Poughquag NY

Wayne J. Howell - Williston VT

Thomas G. Ference - Essex Junction VT -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:H01L 2144

-

US Classification:438108, 438124, 438126, 438127, 438637

-

Abstract:A method for forming three-dimensional circuitization in a substrate is provided for forming conductive traces and via contacts. In the method, a substrate formed of a substantially insulating material is first provided, grooves and apertures in a top surface of and through the substrate are then formed, followed by filling the grooves and apertures with an electrically conductive material such as a solder. The method can be carried out at a low cost to produce high quality circuit substrates by utilizing an injection molded solder technique or a molten solder screening technique to fill the grooves and the apertures. The grooves and the apertures in the substrate may be formed by a variety of techniques such as chemical etching, physical machining and hot stamping.

-

Method For Filling High Aspect Ratio Via Holes In Electronic Substrates And The Resulting Holes

view source -

US Patent:6452117, Sep 17, 2002

-

Filed:May 31, 2001

-

Appl. No.:09/871555

-

Inventors:Brian Eugene Curcio - Binghamton NY

Peter Alfred Gruber - Mohegan Lake NY

Frederic Maurer - Valhalla NY

Konstantinos I. Papathomas - Endicott NY

Mark David Poliks - Vestal NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:H01R 1204

-

US Classification:174262, 174260, 174263, 174264, 174266, 361760, 361795, 361803, 439 65, 257698, 257778, 257737

-

Abstract:High aspect ratio (5:1-30:1) and small (5 m-125 m) diameter holes in a dielectric substrate are provided, which are filled with a solidified conductive material, as well as a method of filling such holes using pressure and vacuum. In certain embodiments, the holes are lined with conductive material and/or capped with a conductive material. The invention also contemplates a chip carrier formed by such material.

Isbn (Books And Publications)

Von Dobler Bis DV-CAM: Ergonomics Fur Amateurfilm Zur Geschichte Der Kinematographie

view sourceAuthor

Peter Gruber

ISBN #

3631340230

Name / Title

Company / Classification

Phones & Addresses

Director

Glen Rose Lions Club

Civic/Social Association

Civic/Social Association

Peter Gruber MD

Emergency Medicine

Emergency Medicine

305 E 161 St, Bronx, NY 10451

7185792500

7185792500

Wikipedia References

Peter Gruber (Footballer)

License Records

Peter Gruber

License #:

E011934 - Expired

Category:

Emergency medical services

Issued Date:

Oct 16, 2009

Expiration Date:

Oct 31, 2011

Type:

Sierra-Sacramento Valley EMS Agency

Resumes

Fo At Globaljet

view sourcePosition:

fo at globaljet

Location:

United States

Industry:

Building Materials

Work:

globaljet

fo

fo

Medicine Doctors

Dr. Peter J Gruber, Bronx NY - MD (Doctor of Medicine)

view sourceSpecialties:

Emergency Medicine

Address:

111 E 210Th St, Bronx, NY 10467

7189202323 (Phone)

WEILER DIVISION-MONTEFIORE HOSPITAL

1825 Eastchester Rd, Bronx, NY 10461

7189206626 (Phone), 7189042517 (Fax)

MONTEFIORE MEDICAL CENTER

1825 Eastchester Rd, Bronx, NY 10461

7189042500 (Phone), 7189042827 (Fax)

7189202323 (Phone)

WEILER DIVISION-MONTEFIORE HOSPITAL

1825 Eastchester Rd, Bronx, NY 10461

7189206626 (Phone), 7189042517 (Fax)

MONTEFIORE MEDICAL CENTER

1825 Eastchester Rd, Bronx, NY 10461

7189042500 (Phone), 7189042827 (Fax)

Certifications:

Emergency Medicine, 2004

Awards:

Healthgrades Honor Roll

Languages:

English

Hospitals:

111 E 210Th St, Bronx, NY 10467

WEILER DIVISION-MONTEFIORE HOSPITAL

1825 Eastchester Rd, Bronx, NY 10461

MONTEFIORE MEDICAL CENTER

1825 Eastchester Rd, Bronx, NY 10461

Jacobi Medical Center

1400 Pelham Parkway South, Bronx, NY 10461

WEILER DIVISION-MONTEFIORE HOSPITAL

1825 Eastchester Rd, Bronx, NY 10461

MONTEFIORE MEDICAL CENTER

1825 Eastchester Rd, Bronx, NY 10461

Jacobi Medical Center

1400 Pelham Parkway South, Bronx, NY 10461

Education:

Medical School

New York Medical College

Graduated: 1988

Medical School

Long Island Jewish Med Center

Graduated: 1988

New York Medical College

Graduated: 1988

Medical School

Long Island Jewish Med Center

Graduated: 1988

Peter J. Gruber

view sourceSpecialties:

Congenital Cardiac Surgery (Thoracic Surgery), Transplant Surgery

Work:

University Of Iowa Cardiac & Thoracic Surgery

200 Hawkins Dr STE SE500GH, Iowa City, IA 52242

3193563440 (phone), 3193563891 (fax)

200 Hawkins Dr STE SE500GH, Iowa City, IA 52242

3193563440 (phone), 3193563891 (fax)

Education:

Medical School

University of Pennsylvania School of Medicine

Graduated: 1992

University of Pennsylvania School of Medicine

Graduated: 1992

Languages:

English

Description:

Dr. Gruber graduated from the University of Pennsylvania School of Medicine in 1992. He works in Iowa City, IA and specializes in Congenital Cardiac Surgery (Thoracic Surgery) and Transplant Surgery. Dr. Gruber is affiliated with University Of Iowa Hospitals & Clinics.

Peter J Gruber, Bronx NY

view sourceSpecialties:

Emergency Medicine

Work:

Montefiore Medical Center

111 E 210Th St, Bronx, NY 10467

MMG-Comprehensive Family Care Center CFCC

305 E 161St St, Bronx, NY 10451

Montefiore Medical Center

600 E 233Rd St, Bronx, NY 10466

111 E 210Th St, Bronx, NY 10467

MMG-Comprehensive Family Care Center CFCC

305 E 161St St, Bronx, NY 10451

Montefiore Medical Center

600 E 233Rd St, Bronx, NY 10466

Education:

New York Medical College (1988)

Peter J Gruber, Bronx NY

view sourceSpecialties:

Emergency Medicine Physician

Address:

111 E 210Th St, Bronx, NY 10467

Board certifications:

American Board of Emergency Medicine Certification in Emergency Medicine

Plaxo

Peter Gruber

view sourceInfineon Technologies Past: Siemens AG

Googleplus

Peter Gruber

Work:

Zep Solar - Senior Product Development Engineer

Peter Gruber

Lived:

Yorktown Heights, NY

Peter Gruber

Peter Gruber

Peter Gruber

Peter Gruber

Peter Gruber

Peter Gruber

Flickr

Peter Gruber

view source

Peter Gruber

view source

Peter Gruber

view source

Peter Gruber

view source

Gruber Peter

view source

Hans Peter Gruber

view source

Peter Gruber

view source

Peter Gruber

view sourceClassmates

Peter Gruber

view sourceSchools:

Middlesex High School Middlesex VA 1981-1985

Community:

Charles Cooke

Peter Gruber | Piedmont B...

view source

Peter Gruber | Foothill M...

view source

Addison Trail High School...

view sourceGraduates:

Annamarie Mancini (1987-1991),

Kristina Kolioulis (2000-2004),

Pete Gruber (1972-1976),

Robert Szuflita (1988-1992)

Kristina Kolioulis (2000-2004),

Pete Gruber (1972-1976),

Robert Szuflita (1988-1992)

Foothill Middle College, ...

view sourceGraduates:

Peter Gruber (1995-1999),

Seth Anison (2005-2009),

Gail Kirk (1992-1996),

Jerry Gaylor (1961-1972),

Evelyn Perez (2005-2009)

Seth Anison (2005-2009),

Gail Kirk (1992-1996),

Jerry Gaylor (1961-1972),

Evelyn Perez (2005-2009)

Youtube

Get Report for Peter A Gruber from Mohegan Lake, NY, age ~69